Carbon-based micro-nano photo-thermal coating layer and preparation method thereof

A micro-nano coating technology, which is applied to coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of poor mechanical properties, optical properties and chemical stability of solar thermal materials, and achieve simple structure, Good thermal stability, the effect of improving absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

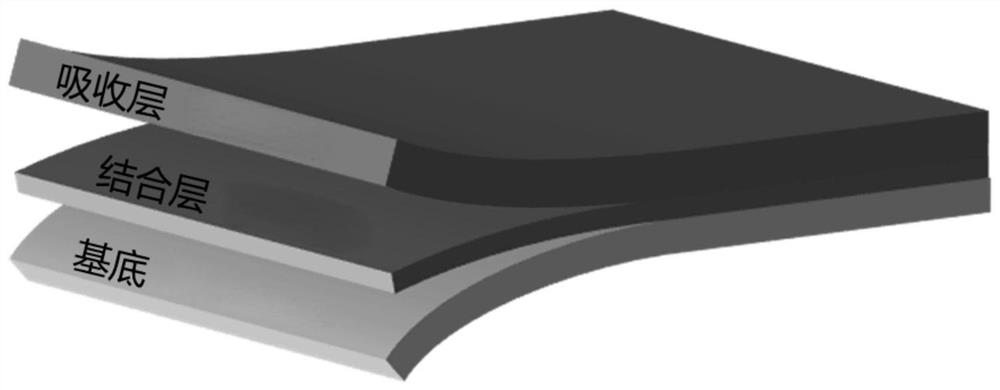

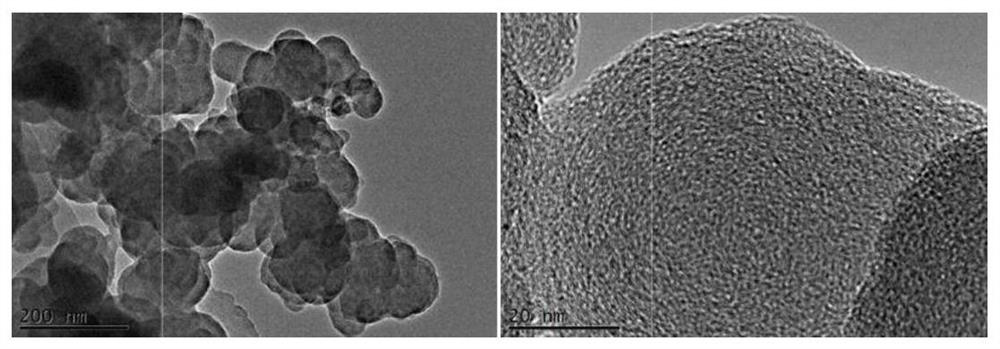

[0039] A preparation method of the above-mentioned carbon-based micro-nano photothermal coating comprises the following steps:

[0040] Use industrial pure aluminum as the base layer material, put it into the spin coater after ultrasonic cleaning and drying; adjust the time and speed of the spin coater to 20s, 500r / min, 60s, 800r / min in turn; use a syringe to extract For 1.5ml of RTV-1, add 1ml dropwise when loading, and when the spin coater starts to work, add the remaining 0.5ml RTV-1 to the base layer through the small hole of the spin coater cover within the first 20s. Before spin-coating, the substrate should be cleaned with ethanol to remove the oxide layer, pollutants and burrs on the surface of the substrate; next, the spin-coated coating should be placed in the air to dry for 10 minutes, and after ultrasonic cleaning for 10 minutes, it will be ignited by physical and chemical deposition. For candles, deposit uniformly at a distance of 2.9 cm from the wick for 2 minute...

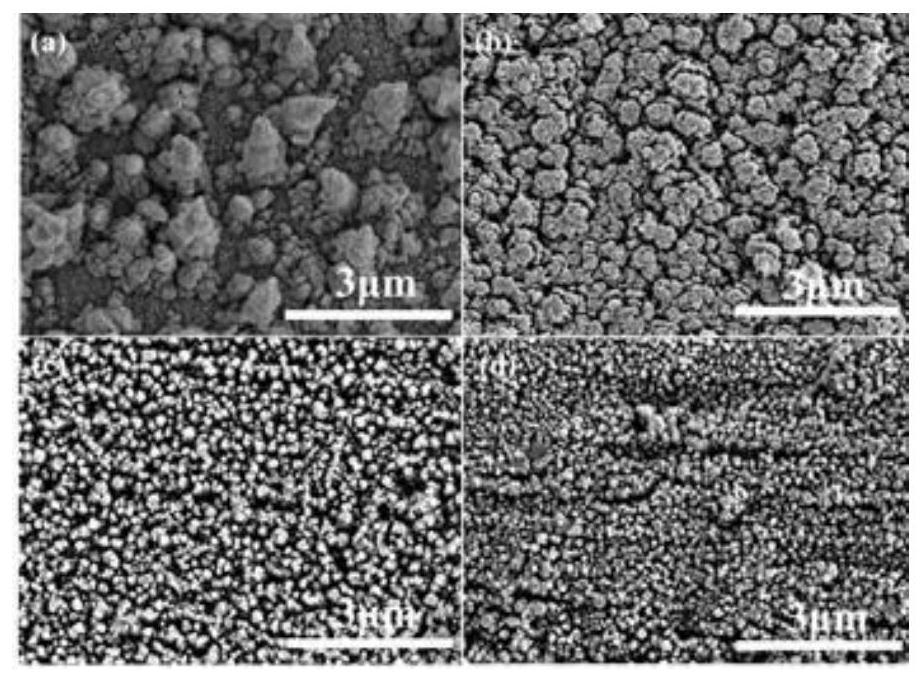

Embodiment 1

[0050] 1. Put the grade 1235 aluminum alloy with surface roughness Ra<1μm, no rust spots and pits on the surface into the spin coater after ultrasonic cleaning and drying;

[0051] 2. Pour anhydrous ethanol with a purity of 99.7% into the beaker, and use the structure of the aluminum alloy to ensure that they do not touch each other. During the ultrasonic cleaning process, keep the internal temperature of the cleaning machine at 28°C, and the height of the water level line is higher than that of the beaker. The height of anhydrous ethanol inside; when wrapping, care should be taken to prevent water from entering the inside of the beaker, and the interior should not allow the substrate and the base to adsorb each other, keep a distance of 1cm, work at a power of 100W, and ultrasonic cleaning time for 30min.

[0052] 3. When spin-coating the bonding layer, use 2 times of spin-coating RTV-1, the motor voltage is 220V, the spin-coating time is 20s, and the spin-coating speed is 500...

Embodiment 2

[0057] 1. Put the grade 1235 aluminum alloy with surface roughness Ra<1μm, no rust spots and pits on the surface into the spin coater after ultrasonic cleaning and drying;

[0058] 2. Pour anhydrous ethanol with a purity of 99.7% into the beaker, and use the structure of the aluminum alloy to ensure that they do not touch each other. During the ultrasonic cleaning process, keep the internal temperature of the cleaning machine at 28°C, and the height of the water level line is higher than that of the beaker. The height of anhydrous ethanol inside; when wrapping, care should be taken to prevent water from entering the inside of the beaker, and the interior should not allow the substrate and the base to adsorb each other, keep a distance of 1cm, work at a power of 100W, and ultrasonic cleaning time for 30min.

[0059] 3. When spin-coating the bonding layer, use 2 times of spin-coating RTV-1, the motor voltage is 220V, the spin-coating time is 20s, and the spin-coating speed is 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Surface finish | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com