Polycrystalline silicon reduction furnace with 48 pairs of rods

A technology of polysilicon and reduction furnace, which is applied in the field of reduction furnace for producing polysilicon and reduction furnace for producing polysilicon by electrochemical reaction, which can solve the problems of affecting product quality cost, large power consumption, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

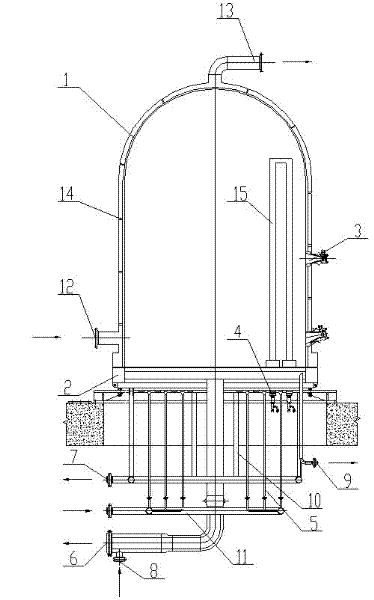

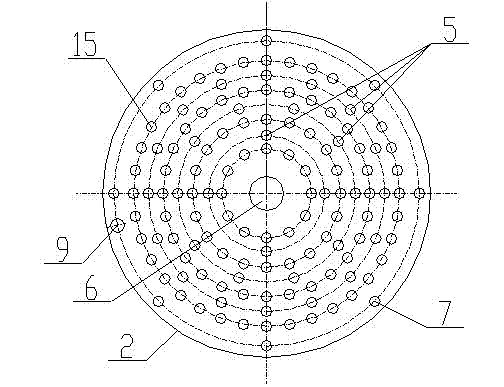

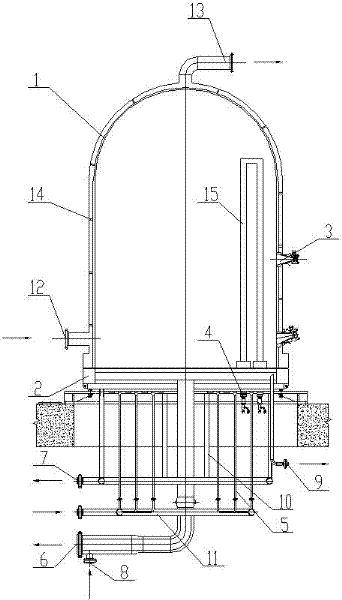

[0015] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the front structure of the 48-pair rod polysilicon reduction furnace of the present invention. figure 2 It is a top view of the chassis of the present invention. Depend on figure 1 of figure 2 It can be seen that the 48 pairs of rod polysilicon reduction furnaces of the present invention include a furnace body 1 and a chassis 2. The furnace body 1 has a cooling water chamber, and the chassis 2 has a water-cooled structure. On the chassis 2, 48 pairs are evenly arranged in four circles. (96) electrodes 4, 18 pairs of electrodes 4 are arranged on the outermost circle of the chassis 2, 14 pairs of electrodes 4 are arranged on the second circle, 10 pairs of electrodes 4 are arranged on the third circle, and 6 pairs of electrodes 4 are arranged on the innermost circle. The positive and negative poles of the electrodes 4 are arranged on the chassis 2 at intervals one by one.

[0016] There are 30 evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com