Electroplastic auxiliary cold spraying device and coating preparation method

An electroplastic and cold spraying technology, applied in the field of conductive powder, can solve the problems of high performance parameters of cold spraying device, difficult to guarantee bonding strength, unfavorable coating growth, etc., so as to overcome uncoordinated deformation and improve the microstructure state. , Improve the effect of coating deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

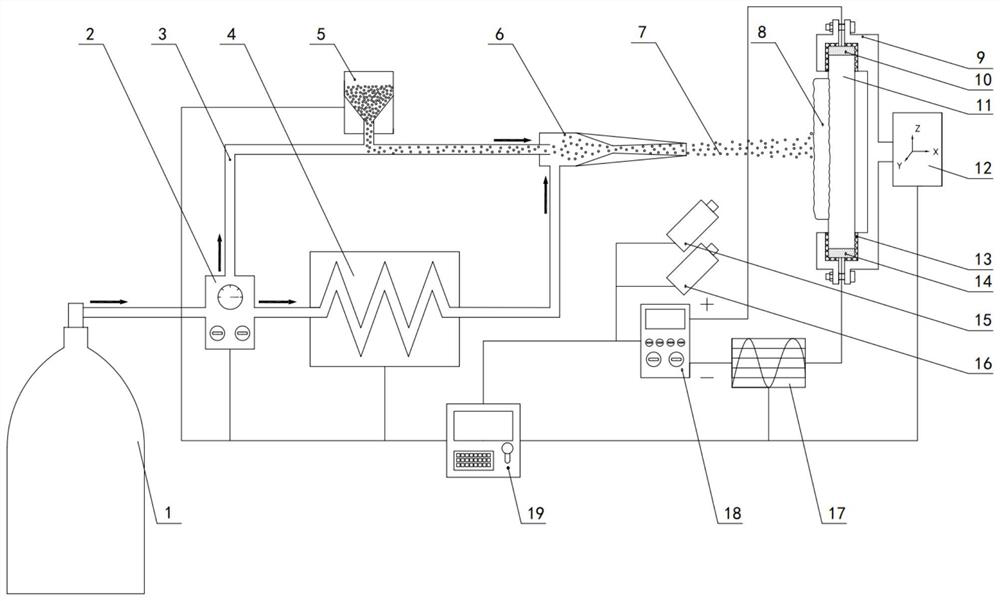

[0025] see figure 1 As shown, the electroplastic assisted cold spraying device of the present invention includes a gas storage tank 1, a gas valve 2, a gas heater 4, a powder feeder 5, a Laval nozzle 6, a sample table 12 and several gas pipelines 3 . Wherein, the air valve 2 has 1 input port and 2 output ports, and the Laval nozzle 6 has 2 input ports and 1 output port. The gas outlet of the gas storage tank 1 is connected to an input port of the gas valve 2 through the gas pipeline 3, and the first output port of the gas valve 2 is connected to the first input port of the Laval nozzle 6 through the gas pipeline 3, and the gas valve 2 The second output port of the gas heater 4 is connected to the input port of the gas heater 4 through the gas pipeline 3, and the output port of the gas heater 4 is connected to the second input port of the Laval nozzle 6 through the gas pipeline 3. The output port of the Laval nozzle 6 is arranged horizontally, facing the sprayed surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com