Electroplastic rotary pressing device

A technology of electroplasticity and energization device, applied in the field of electroplastic spinning device, can solve the problems of reducing plastic deformation resistance, poor plasticity, etc., and achieve the effects of reducing plastic deformation resistance, improving efficiency, and low cost and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

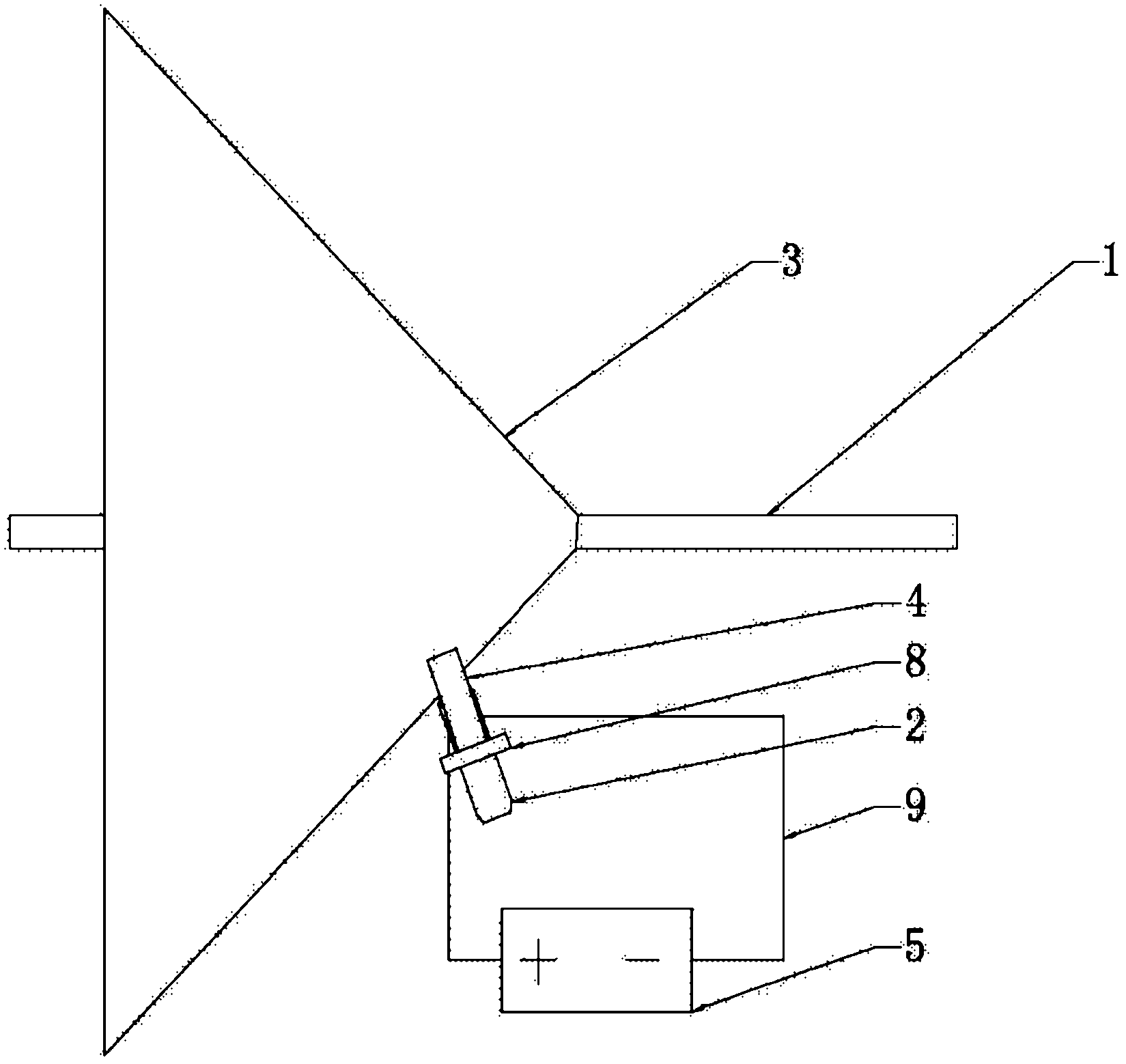

[0023] Such as figure 1 As shown, this embodiment includes: a main shaft 1, a rotary wheel 2, a blank 3, a power supply 4, a pulse power supply 5, a spring 6, a conductive rod 7, a spinning frame 8 and a wire 9, wherein the external pulse power supply 5 passes through the wire 9 It is connected to the energizing device 4, and the two energizing devices 4 are respectively connected to the positive and negative poles of the pulse power supply 5.

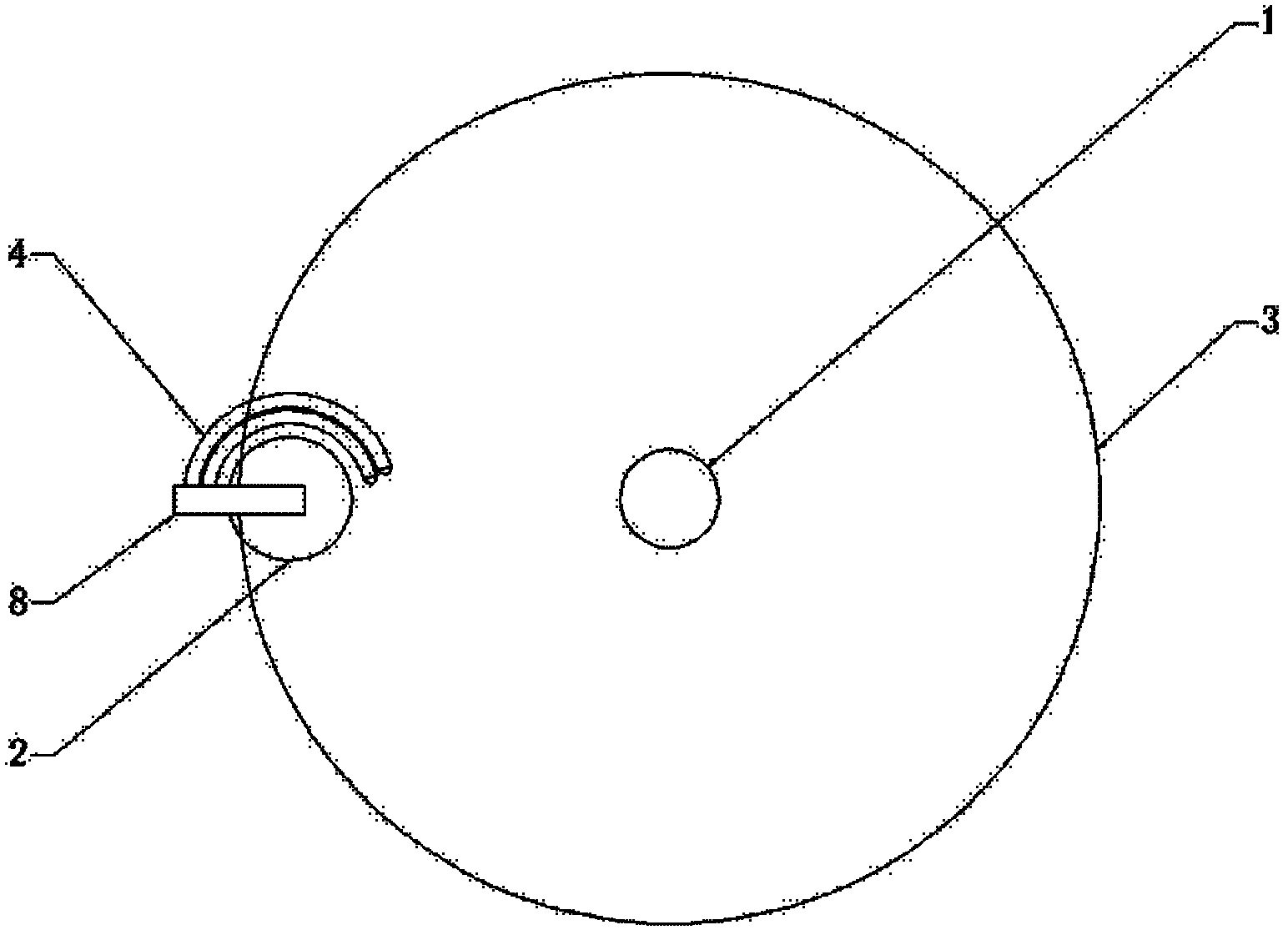

[0024] Such as figure 2 As shown, there are two electrification devices 4, which are distributed on one side of the rotary wheel 2, and are on the same plane as the rotary wheel 2. The devices 4 are all fixed on the wheel frame 8 so that they can move synchronously with the wheel 2 .

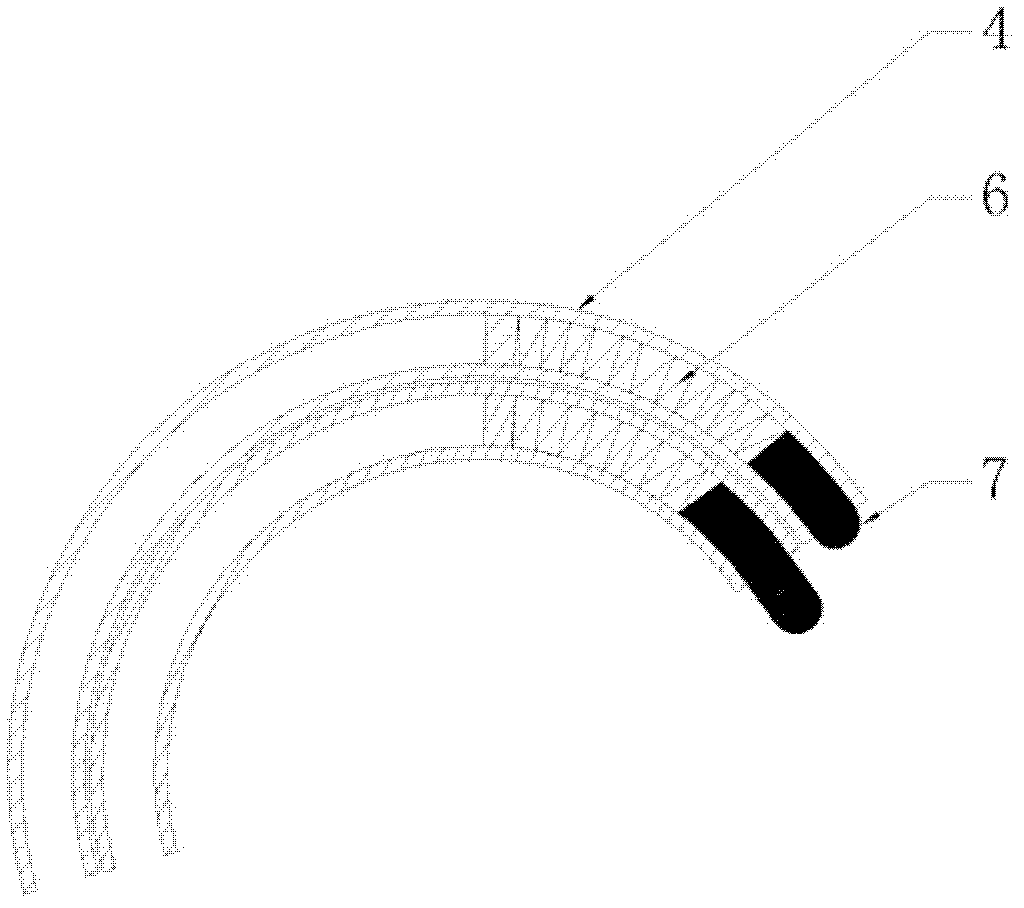

[0025] Such as image 3 As shown, the shell of the energizing device 4 is insulated, and there is a conductive rod 7 inside. The head of the conductive rod 7 is hemispherical, so that it can form surface contact with the blank 3 under pressure, and t...

Embodiment 2

[0029] In this implementation example, the blank to be processed is a tungsten-copper refractory alloy, which is circular, with a diameter of 1100mm and a thickness of 1.5mm. The process parameters of the continuous pulse power output pulse current are: peak current 2000A, frequency 300HZ, pulse width 40μs , duty cycle 10%.

[0030] This embodiment is the same as other implementations of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com