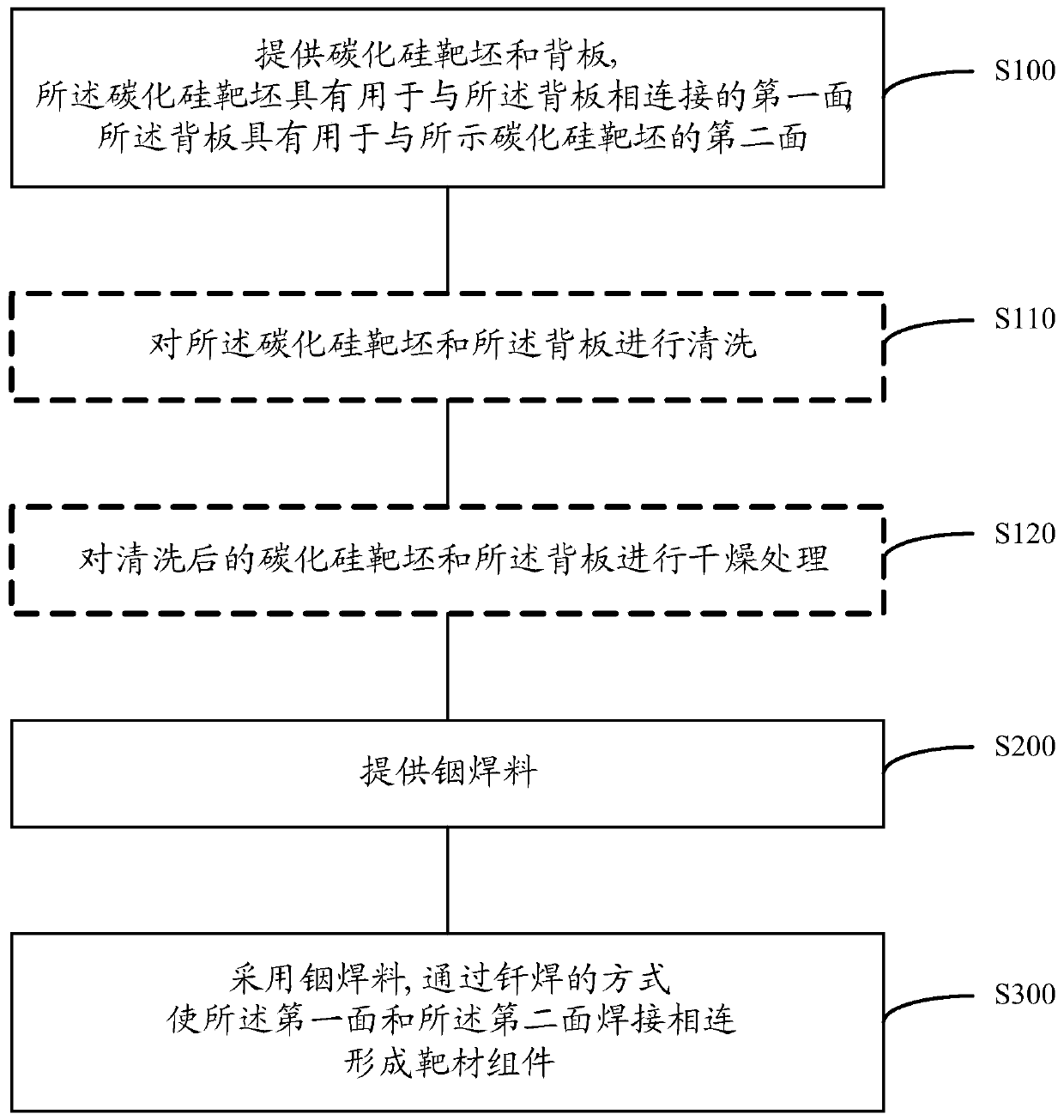

Manufacturing method of target assembly

A manufacturing method and component technology, applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve problems such as low yield, and achieve the effects of improving yield, easy plastic deformation, and reducing fragmentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

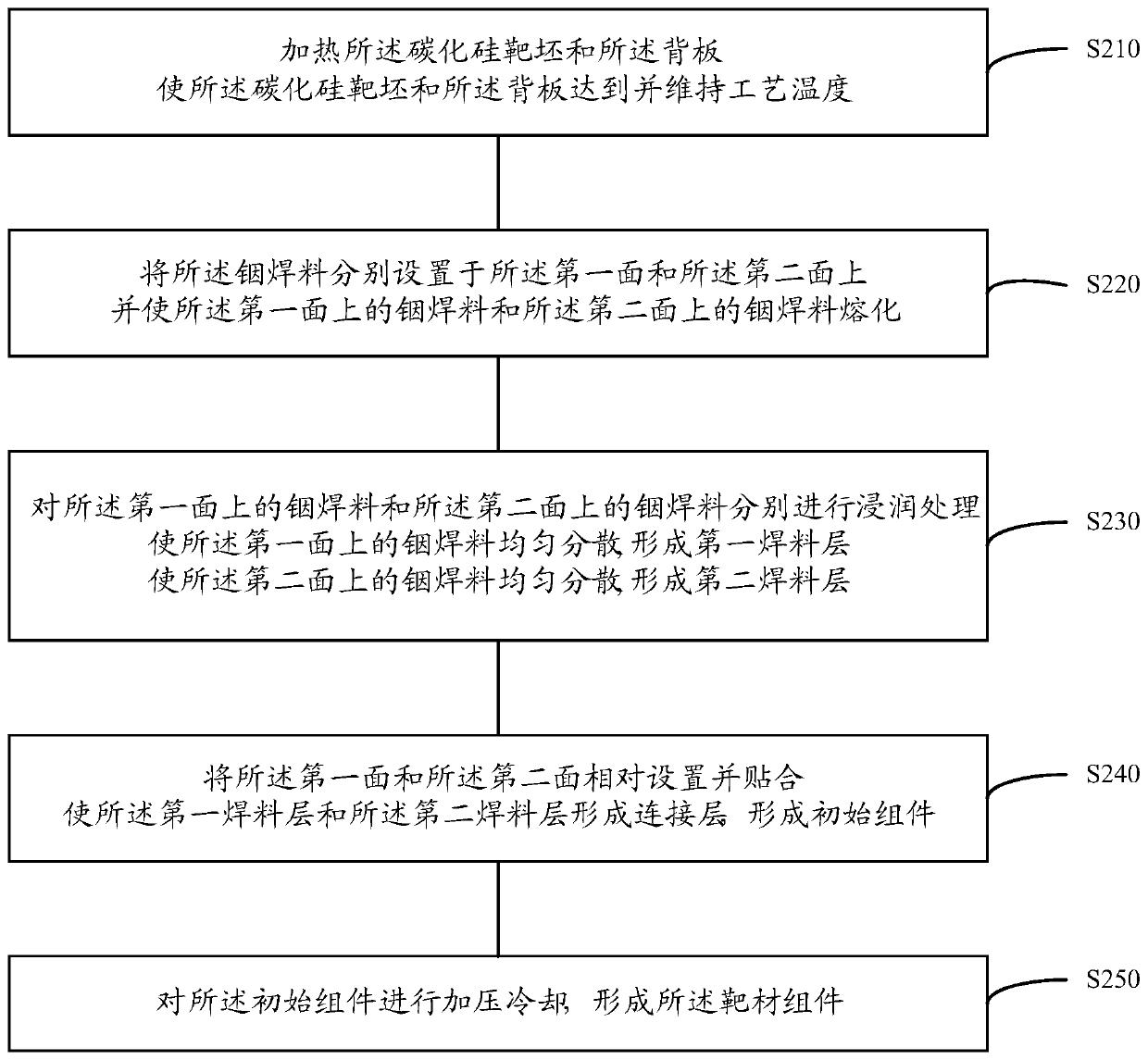

Method used

Image

Examples

Embodiment Construction

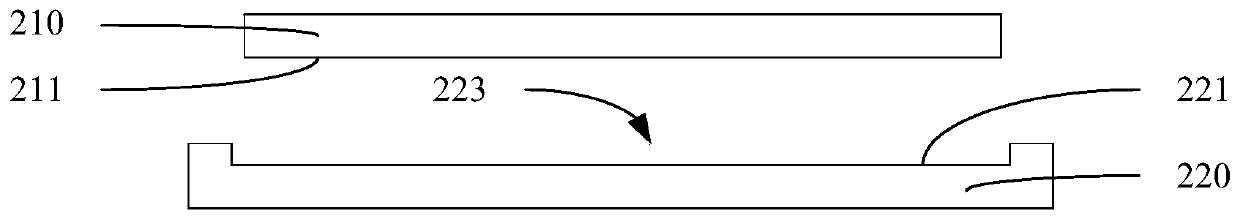

[0035] It can be seen from the background art that the silicon carbide target assembly in the prior art has the problem of low yield. Now combined with the structure of the silicon carbide target component to analyze the reasons for its low yield:

[0036] The silicon carbide target assembly is formed by welding the silicon carbide target blank and the back plate by using solder. In the prior art, the method of manufacturing silicon carbide target components usually uses tin solder to realize the welding of the two.

[0037] Silicon carbide material is relatively brittle, and it is prone to cracking during the manufacturing process of target components. Moreover, tin solder has high hardness after cooling and solidification, and it is difficult to play a buffering role between the silicon carbide target blank and the back plate. Therefore, in the prior art, tin solder is used to connect the silicon carbide target blank and the back plate by welding. SiC target blanks are pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com