Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

A technology of porous ceramics and ceramic materials, applied in the field of porous ceramic powder filter material and its manufacturing, can solve problems such as coating pressure drop exceeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

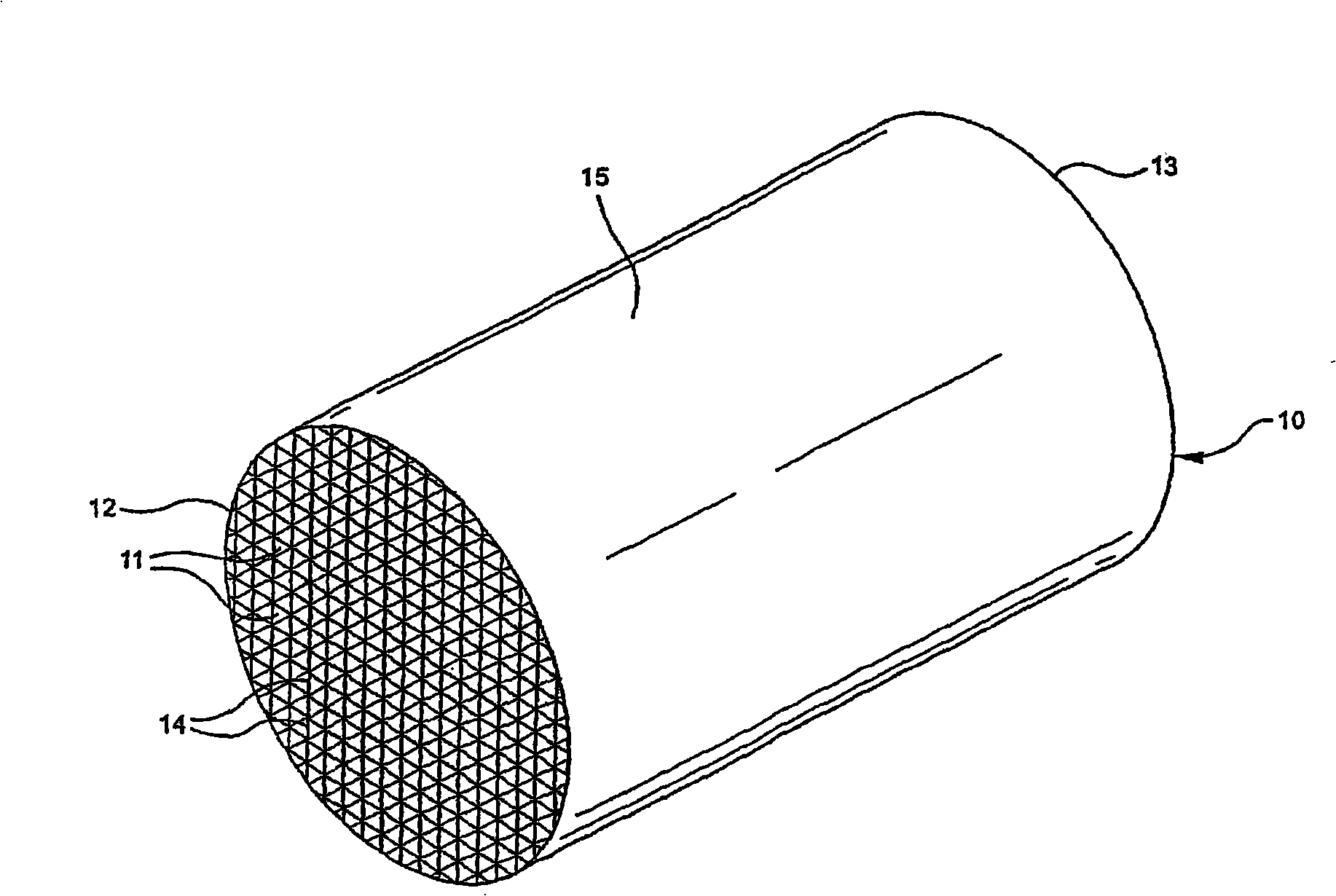

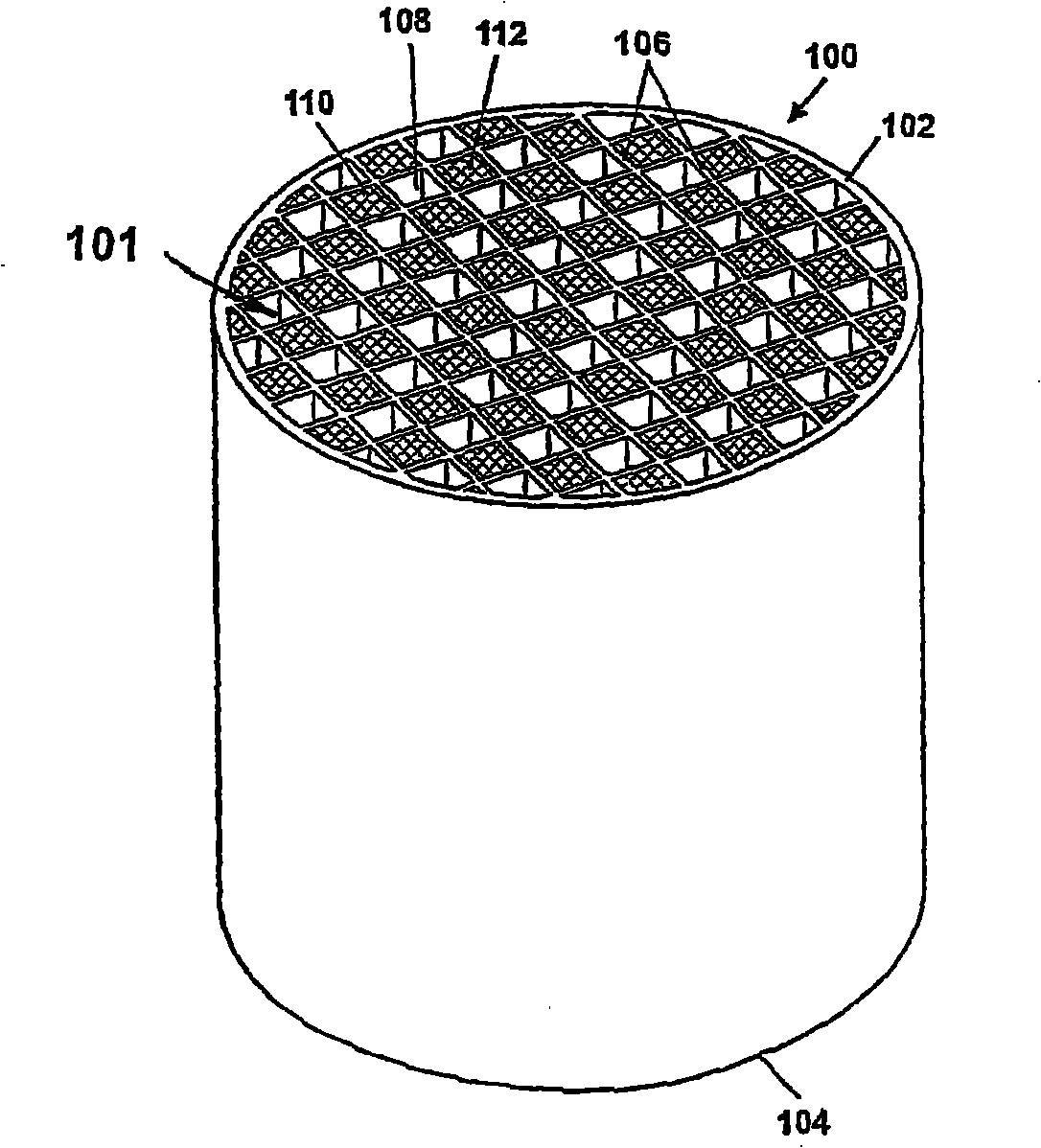

[0076] Such as figure 1 As shown, take dry component, wherein comprise each example pore forming agent of the present invention listed in table 2 and molding aid (such as cellulose materials such as methyl cellulose, and sodium stearate), prepared cordierite Green body 10 serves as an example of the present invention. The dry ingredients are then mixed with a solvent carrier such as water and agitated in a preferably stainless steel grinder to form an extrudable plastic compound. The plasticized mass is then shaped, preferably extruded, into a green body as described in US 5,205,991 et al. After extrusion, the porous honeycomb green bodies were cut to record lengths.

[0077] The extruded green body 10 has a honeycomb structure having a plurality of substantially parallel celled honeycomb channels 11 formed at least in part of intersecting honeycomb walls 14 (otherwise referred to as a "network") extending from a first end 12 extends to the second end 13. The green body 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com