Ultrafast laser processing method and device of transparent material

A technology of transparent materials and processing methods, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as processing limitations, and achieve the effects of stable laser output, improved removal efficiency, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

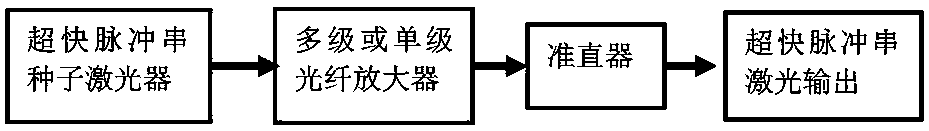

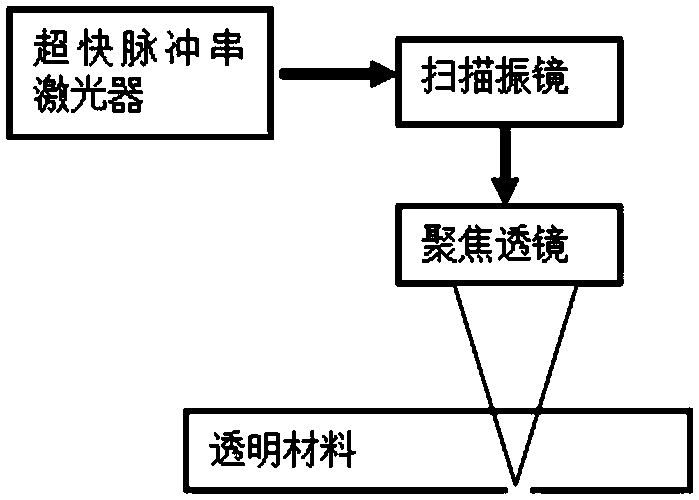

[0039] Embodiment one: see figure 2 As shown, a transparent material processing device is composed of an ultrafast pulse train laser, a scanning galvanometer, and a focusing lens. See figure 1 , the ultrafast pulse train laser is mainly composed of a pulse train seed laser with an output wavelength between 1020 nm and 1090 nm, a multi-stage or single-stage fiber amplifier, and a collimator, and the output light of the pulse train seed laser passes through the fiber amplifier After amplified, the collimator outputs a laser pulse train after being collimated; the laser pulse train is focused on the position of the transparent material to be processed by the focusing lens after passing through the scanning galvanometer.

[0040] In this embodiment, the scanning galvanometer is a three-dimensional galvanometer, the repetition rate of the laser is 600,000 total pulses per second, the pulse width is 180ps, the number of laser pulses in the pulse train is 2, and each pulse in the pu...

Embodiment 2

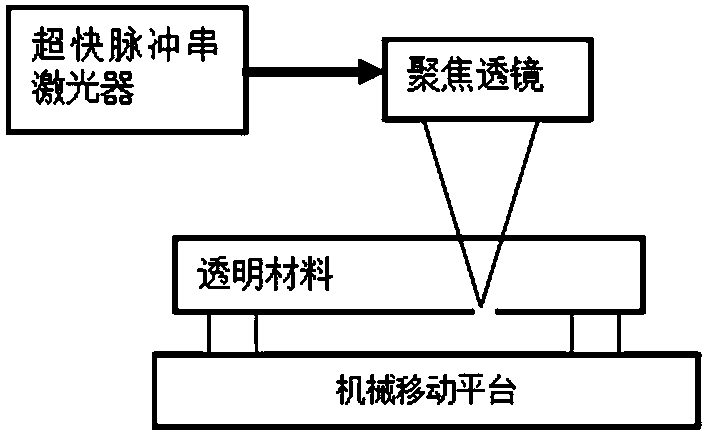

[0041] Embodiment two: see attached image 3 As shown, a transparent material processing device is composed of an ultrafast pulse train laser and a focusing lens, see figure 1 , the ultrafast burst laser is mainly composed of an ultrafast burst seed laser with an output wavelength between 1020 nm and 1090 nm, a multi-stage or single-stage fiber amplifier, and a collimator, and the output light of the burst seed laser is passed through After being amplified by the fiber amplifier, the collimator outputs a laser pulse train after being collimated; the laser pulse train is focused on the position of the transparent material to be processed by the focusing lens.

[0042] In this embodiment, the pulse train laser is focused on the transparent material by the lens, the lens is installed on the moving belt, and the linear cutting is realized by moving the lens, the transparent material is arranged on the mechanical moving platform, and the transparent material is relatively relativel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Peak power | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com