Wet clutch friction plate surface groove profile line optimization method

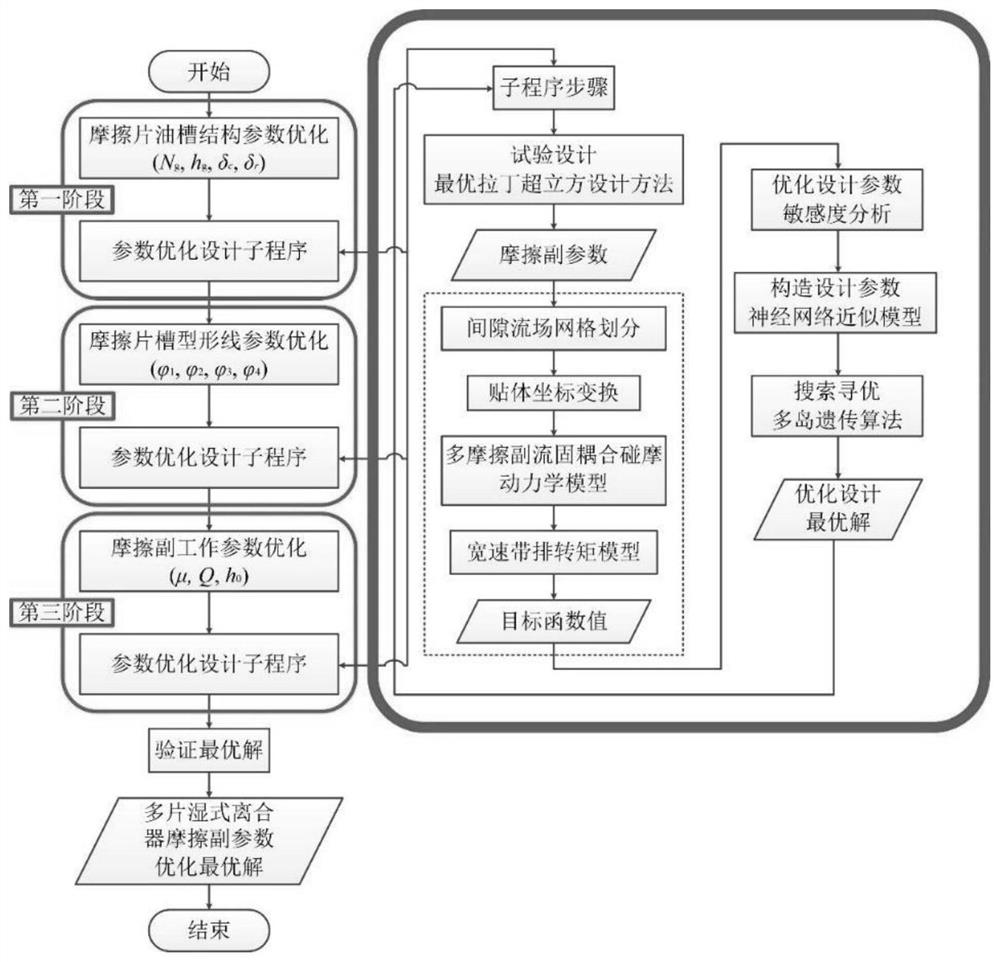

A wet clutch and optimization method technology, applied in the field of vehicle clutch friction plates, can solve problems such as engine power consumption, thermal damage failure, reduction of hydraulic transmission system efficiency, etc. The effect of reducing displacement torque, rubbing frequency and axial rubbing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

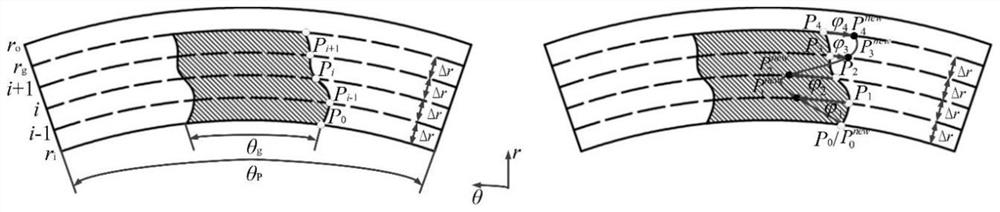

[0041] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as figure 2 As shown in , it is a schematic diagram of parametric representation and optimization of any oil tank shape line by curve interpolation method (the shaded part is the tank area), where r g is the outer radius of the groove area on the surface of the friction plate, θ p (θ p =2π / N g ) is the circumferential angle corresponding to a periodic structure of the friction plate, θ g is the circumferential angle corresponding to the groove area, P i is the discrete point of the given oil groove shape line, the subscript i is the number of the discrete point, and the i-th discrete point P on the groove shape line i The coordinates in the cylindrical coordinate system are (r i ,θ i ), for the convenience of modeling, each discrete point P on the groove shape line of the oil tank i Distributed equidistantly along the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com