Transverse swing control method for wheel-rail low-power bogie

A technology of lateral swing and low power, applied in the field of railway wagon manufacturing, can solve problems such as inconvenient maintenance and unstable positioning, and achieve the effects of reducing unsprung mass, reducing operation and maintenance costs, and reducing dynamic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

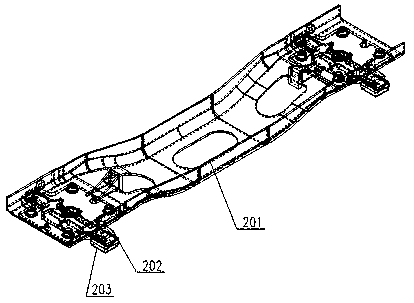

[0028] as attached Figure 2-4 As shown, the present invention relates to a novel wheel-rail low dynamic action bogie comprising the above-mentioned side frame lateral swing control device, including a side frame lateral swing control device (101), a wheel set (102), a rolling bearing device (103), a bearing Saddle (104), eight-shaped rubber elastic pad (105), side frame composition (106), bolster composition (107), central suspension damping device (108), constant contact elastic side bearing (109) and foundation braking device (110).

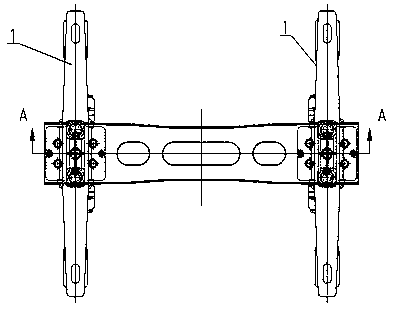

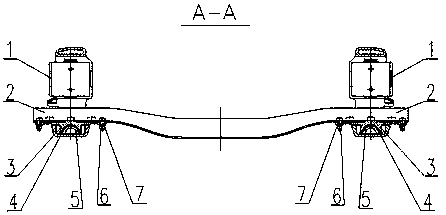

[0029] The side frame swing control device includes a side frame (1), a spring support plate (2), a spring bearing seat (3), a spherical wear-resistant liner (4), and a spherical positioning seat (5).

[0030] Two spherical positioning seats (5) are arranged on the installation surface of the lower chord inner cavity of the central frame of the two side frames (1) arranged in parallel, and are symmetrical along the lateral direction of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com