Preparation method of high-density cold sprayed metal deposition body based on mixed powder

A technology of mixing powder and cold spraying, applied in the field of material engineering, to achieve the effect of poor fluidity, high deposition efficiency, and high flight speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

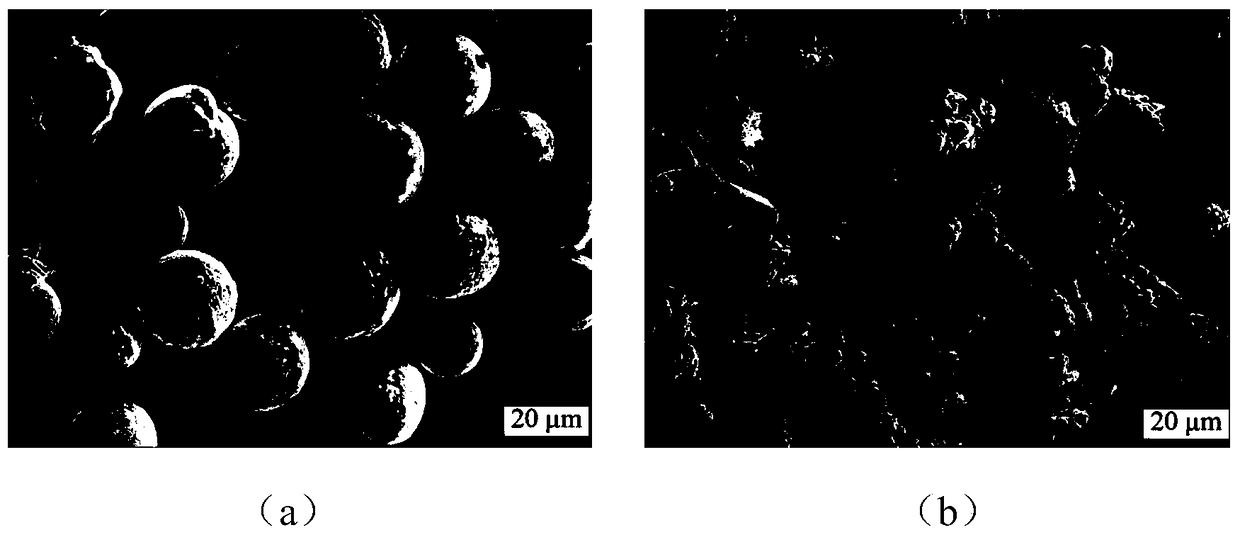

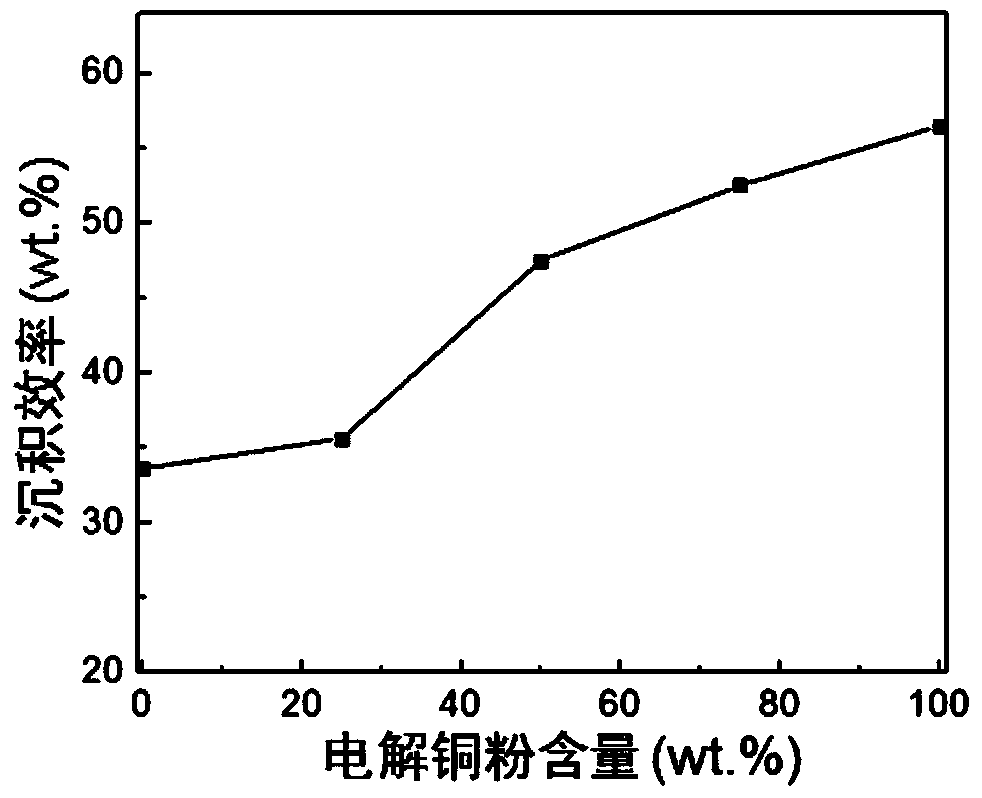

[0042] Metal pure copper is widely used as an electrical and thermal conductive part due to its high electrical and thermal conductivity. For the Cu system, the roller ball mill will be as follows figure 1 The particle size distribution shown in (a) and (b) are both spherical atomized Cu powder and dendritic electrolytic Cu powder with a particle size distribution of 10-30 μm, which are fully mixed according to the mass ratio of 3:1, 1:1, and 1:3, respectively. , to obtain the desired mixed powder.

[0043] As a comparison, pure atomized Cu powder and pure electrolytic Cu powder were used to prepare coatings under the same spraying parameters. Choose 304 stainless steel with a thickness of 3mm as the substrate, clean and dry the surface of the substrate with acetone before spraying, and then use 40# brown corundum sand to roughen the surface of the substrate by sandblasting under the condition of compressed air pressure of 0.6MPa Treatment, so that the roughness can reach Ra...

Embodiment 2

[0046] Studies have shown that pure Ni coating has excellent resistance to neutral salt solution, acid solution and high temperature molten salt corrosion resistance. Unlike the Ni coating produced by the electroplating process, which produces a large amount of waste liquid containing heavy metals, the cold spraying process will not cause environmental pollution, which is a green material preparation technology. The compactness of the coating is critical to corrosion performance. However, studies have shown that the use of conventional atomized Ni powder can only be achieved when expensive helium is used as the accelerating gas, or the powder is preheated to above 600°C with a special device at a higher particle velocity (>600m / s). A dense Ni coating is obtained.

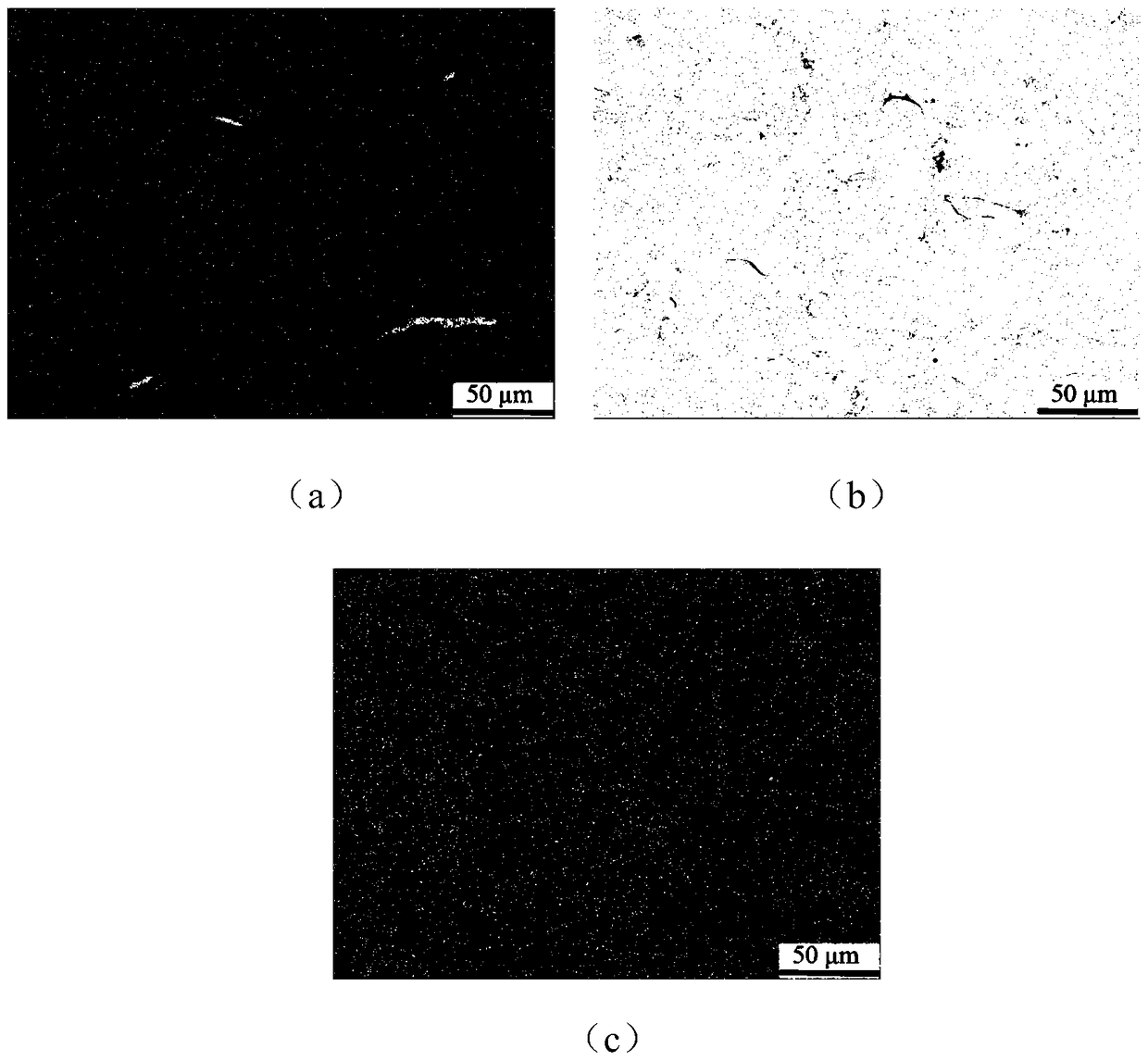

[0047] see Figure 5 , wherein, (a) the morphology of the electrolytic nickel powder, (b) the section of the electrolytic nickel powder, (c) the morphology of the gas atomized nickel powder, (d) the section of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com