Vacuum electric scanning supersonic spray deposition laser additive manufacturing device

A spray deposition and laser additive technology, which is applied in the direction of manufacturing auxiliary devices, processing and manufacturing, and manufacturing tools, can solve the problems of affecting the forming effect of parts, high cost of forming powder, and large amount of forming powder, so as to improve spraying. Working environment, good consistency, and the effect of improving sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

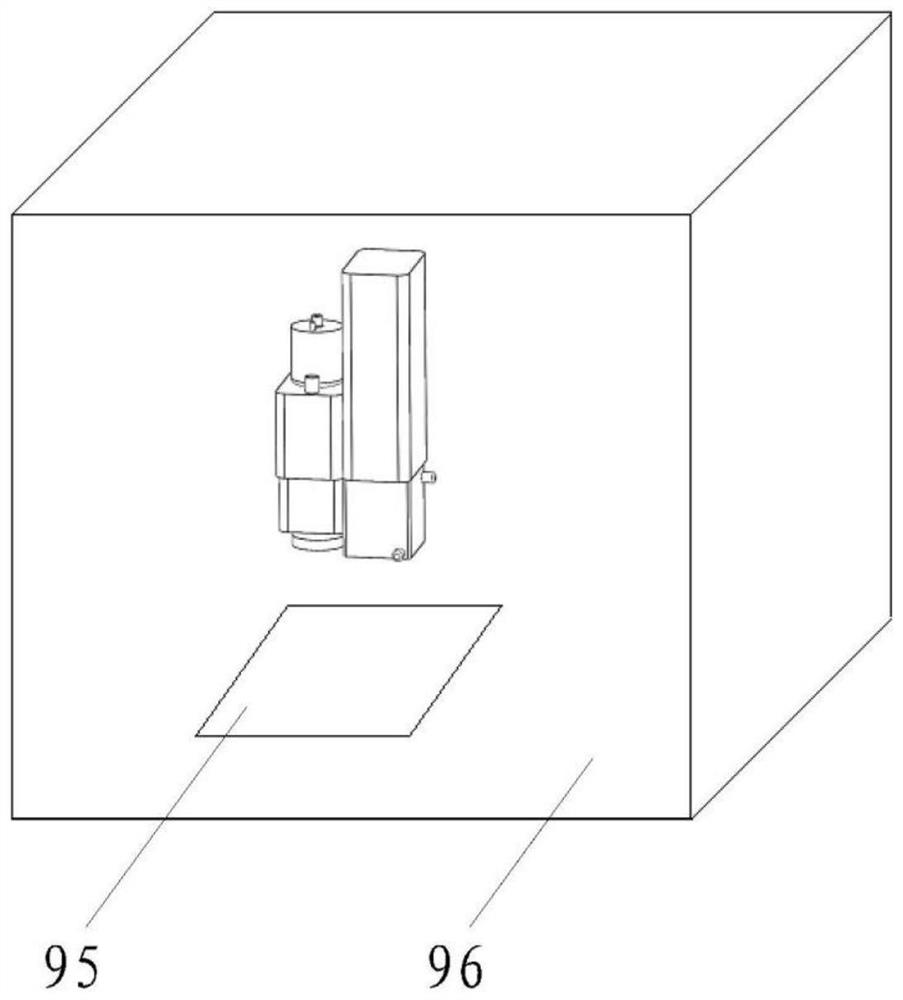

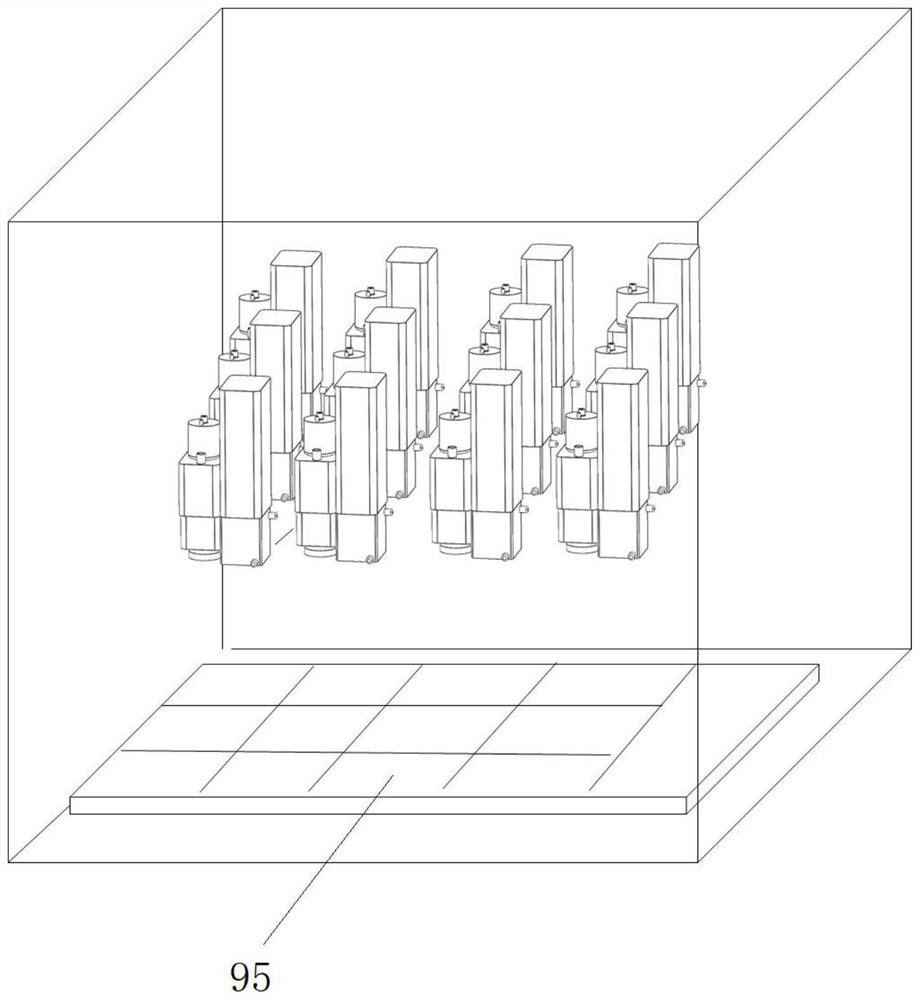

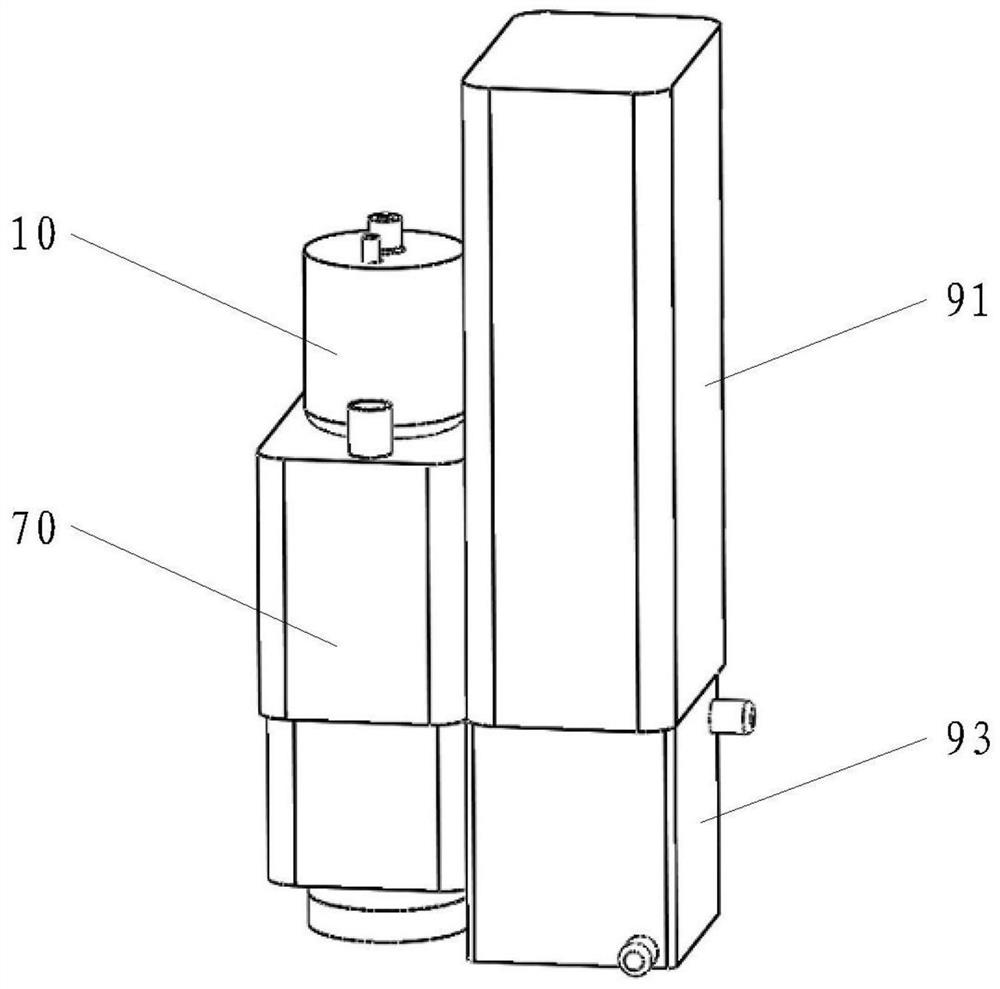

[0025]As shown, the vacuum electrical sweep ultrasonic sprout in this embodiment includes a forming table 95 and a laser injection adder device mounted above the table, the laser injection adding device including cold. The nozzle, the laser generator 91, and the laser beam control device, the cold shot head ejection direction adjustable to the discharged powder particle beam based on the partial scan on the workbench, the laser beam control device is mounted to the laser generator exit Used to control the transmission direction of the laser beam such that the laser beam is discharged from the powder particle beam to the cold nozzle, and the powder particles are heated to form a molten state.

[0026]Combinefigure 1 withfigure 2 As shown, the table and laser injection adding device are mounted within the forming hood 96, wherein the laser injection adder device is mounted on top of the shaped cover, which is a closed structure, and can be set to a vacuum environment in the forming cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com