Superhigh-temperature ceramic densification method based on defect regulation and control and superhigh-temperature ceramic

A technology of ultra-high temperature ceramics and densification, applied in the field of ultra-high temperature ceramics, can solve the problems of high raw material cost, low powder sintering activity, low defect concentration, etc., and achieve the effect of simplifying the sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

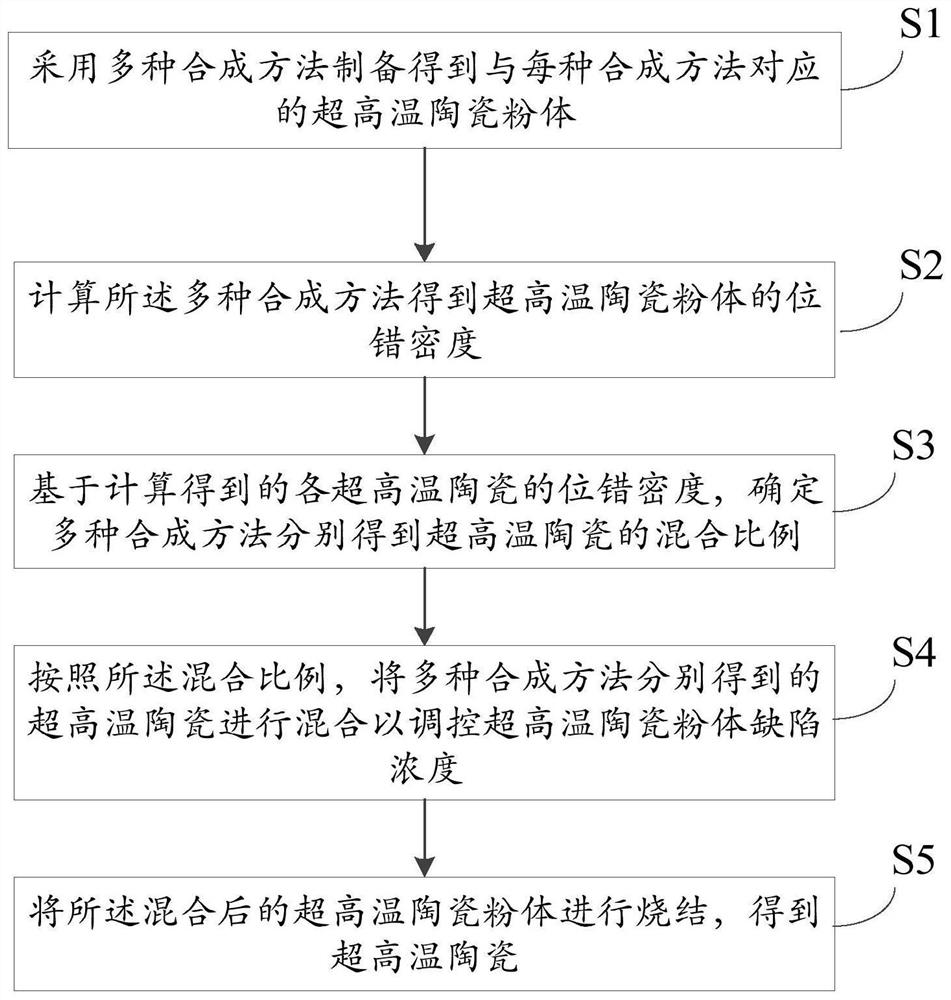

[0041] In the embodiment of the present invention, the various synthesis methods may include high-temperature self-propagation method, carbothermic reduction method, sol-gel method, hydrothermal / solvothermal method, plasma synthesis method, precursor synthesis method, etc.; The sintering method of the ultra-high temperature ceramic powder may include: hot pressing sintering, isostatic pressing sintering, hot isostatic pressing sintering, gas pressure sintering, microwave sintering, spark plasma sintering, and the like.

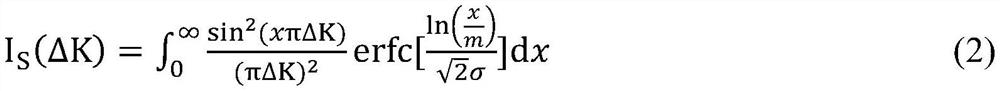

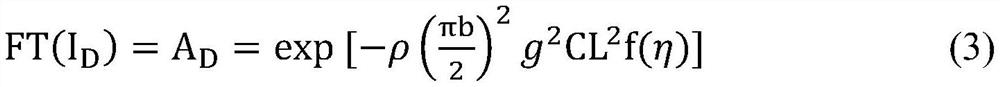

[0042]Usually, there are a large number of dislocations in the powder, and the amount of these dislocations is represented by the dislocation density, which is defined as the total length of the dislocation lines contained in a unit volume of crystal; One definition is: the number of dislocation lines passing through a unit cross-sectional area, also in units of 1 / square centimeter. Generally speaking, when the powder has a higher dislocation density, it can h...

Embodiment 1

[0066] Preparation of ZrB by Self-Propagation and Carbothermal Reduction 2 powder;

[0067] The powder obtained by the self-propagating method and the powder obtained by the carbothermic reduction method were respectively obtained by X-ray diffraction to obtain basic data such as diffraction curves and lattice parameters, and the dislocation density of the two powders was calculated by the CMWP-fit method, and the self-propagating method was calculated. ZrB prepared by 2 The powder dislocation density is 8.68×10 15 m -2 , ZrB prepared by carbothermal reduction method 2 The powder dislocation density is 6.49×10 11 m -2 ;

[0068] Mix the two powders, in which the self-propagating method ZrB 2 The proportion of powder is 25%, and the calculated and adjusted dislocation density of the powder is 2.67×10 15 m -2 ; The regulated powder is densified by hot pressing and sintering to obtain ZrB 2 ceramics.

[0069] According to the calculation results, the calculated ZrB 2 ...

Embodiment 2

[0071] Preparation of ZrB by self-propagating and sol-gel methods 2 powder;

[0072] The powder obtained by the self-propagating method and the powder obtained by the sol-gel method were respectively obtained by X-ray diffraction to obtain basic data such as diffraction curves and lattice parameters, and the dislocation density of the two powders was calculated by the CMWP-fit method, and the self-propagating method was obtained. Prepared ZrB 2 The powder dislocation density is 8.68×10 15 m -2 , ZrB prepared by carbothermal reduction method 2 The powder dislocation density is 6.49×10 11 m -2 ;

[0073] Mix the two powders, in which the self-propagating method ZrB 2 The proportion of powder is 50%, and the calculated and adjusted dislocation density of the powder is 5.41×10 15 m -2 , the regulated powder was densified by pressureless sintering to obtain ZrB 2 ceramics.

[0074] According to the calculation results, the calculated ZrB 2 Powder dislocation density, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com