A kind of preparation method of diamond ultra-thin cutting grinding wheel

A technology for cutting grinding wheels and diamonds, which is used in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc. It can solve the problem of difficulty in ensuring powder flatness and uniformity, uneven thickness and size of blanks, and low grinding and thinning efficiency. and other problems, to achieve the effect of realizing batch automatic production, simplifying manual loading and shortening grinding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add the required metal powder into the three-dimensional mixer in proportion and mix for 2 to 4 hours, then add pickled 140 to 3000 mesh diamond powder (preferably W40), and continue to mix for 2 to 4 hours to obtain the mixture ;

[0027] (2) Fill the cold-pressing mold with the above-mentioned mixture, fill it evenly, scrape it flat, and carry out cold-pressing under a pressure of 10-25 MPa (preferably 10-20 MPa) to obtain a cold-pressed blank;

[0028] (3) Put the above-mentioned cold-pressed blank into a graphite mold, and carry out vacuum sintering to obtain a sintered blank. The temperature of the above-mentioned vacuum hot-press sintering is 550-950°C, the pressure is 15-60KN, and the heating rate is 20-90°C / min , the holding time is 5-15min, the cooling rate is 20-90°C / min; preferably, the vacuum hot-pressing sintering temperature is 600-900°C, the pressure is 15-50KN, the heating rate is 20-70°C / min, and the heat preservation The time is 5-10 minutes, and ...

Embodiment 2

[0034] Taking a diamond ultra-thin cutting grinding wheel with a thickness of 0.2 mm, an outer diameter of 58 mm, and an inner diameter of 40 mm as an example, W40 diamond is used, and the diamond particle size is 40 μm. The method for preparing the grinding wheel includes the following steps:

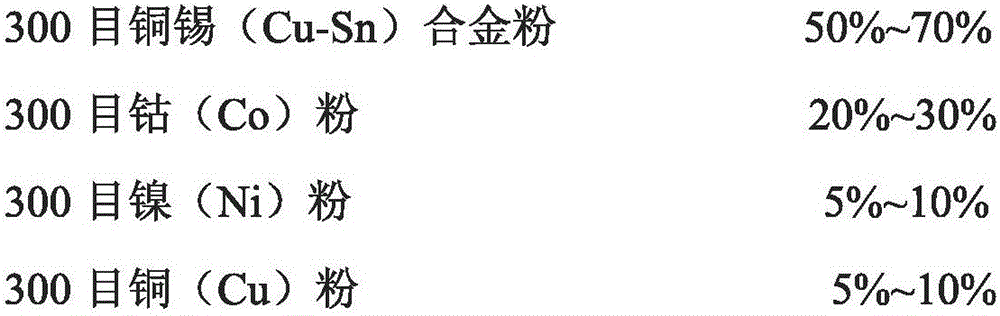

[0035](1) According to the following mass ratio, add the required metal powder into the three-dimensional mixer and mix for 2 hours, then add the pickled diamond powder, and continue mixing for 3 hours to obtain the mixture:

[0036]

[0037] The volume fraction of diamond particles is 12.5%;

[0038] (2) Fill the above-mentioned mixture into the cold-pressing mold, fill it evenly, scrape it flat, place it on the operating table of the cold press and press it cold-pressed to obtain a cold-pressed blank of a metal bond diamond thick cutting grinding wheel, with a pressure of 10-15 MPa; Size: inner diameter 40mm, outer diameter 58mm, thickness 30mm;

[0039] (3) Put the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com