High-power laser diode horizontal linear array pumped solid laser cavity

A laser diode and solid-state laser technology, applied in the field of solid-state laser cavity, can solve the problems of difficult sintering process, limited pump power, complicated system structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

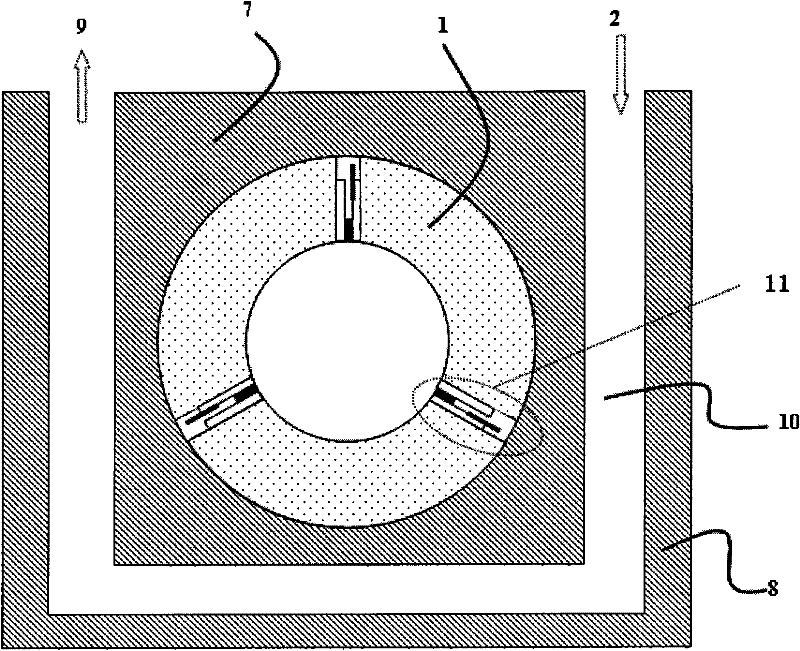

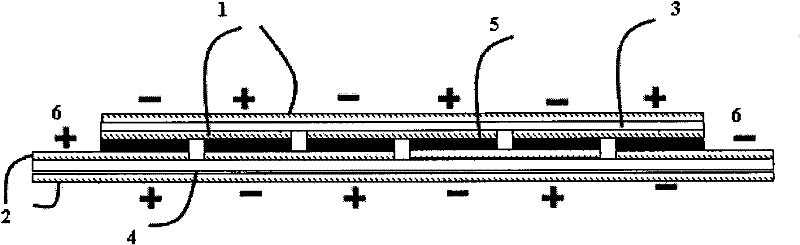

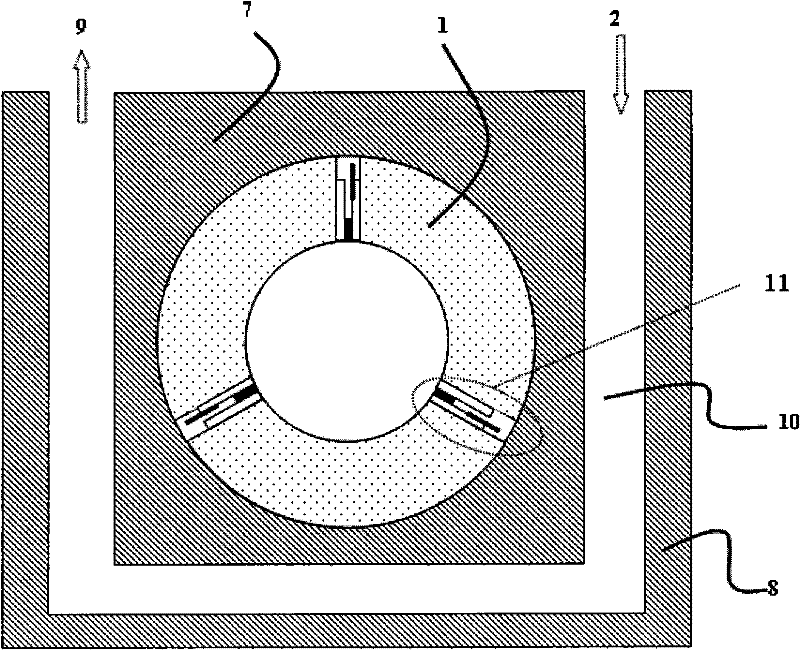

[0016] Example 1: see figure 1 As shown, it is a schematic cross-sectional view of a high-power laser diode horizontal linear array pumped solid laser cavity structure provided by this embodiment. in figure 1 Among them, three horizontal linear arrays of laser diodes 11 are respectively connected with three arc-shaped heat sinks 1 to form a circle. The arc-shaped heat sinks form a cylindrical surface with a highly reflective inner surface, and the cylindrical surface is a pumping cavity. The inner surface of the arc heat sink can be polished and then plated with gold to form a highly reflective surface or coated with a highly reflective dielectric film.

[0017] The arc-shaped heat sink 1 is placed in the through hole of the inner wall 7 of the water-cooled heat sink. A cooling water channel 10 is formed between the inner wall 7 of the water-cooled heat sink and the outer wall 8 of the water-cooled heat sink for heat dissipation. The cooling water flows into the inlet 2 of the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com