Ultra-precision horizontal micro-EDM machine tool

A micro-EDM and ultra-precise technology, applied in the direction of electric processing equipment, metal processing equipment, attachments, etc., can solve the problems that the debris cannot be cleaned, cannot meet the processing requirements, and the processing position is shifted, so as to achieve simple structure and guarantee The effect of placing the position and improving the precision of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

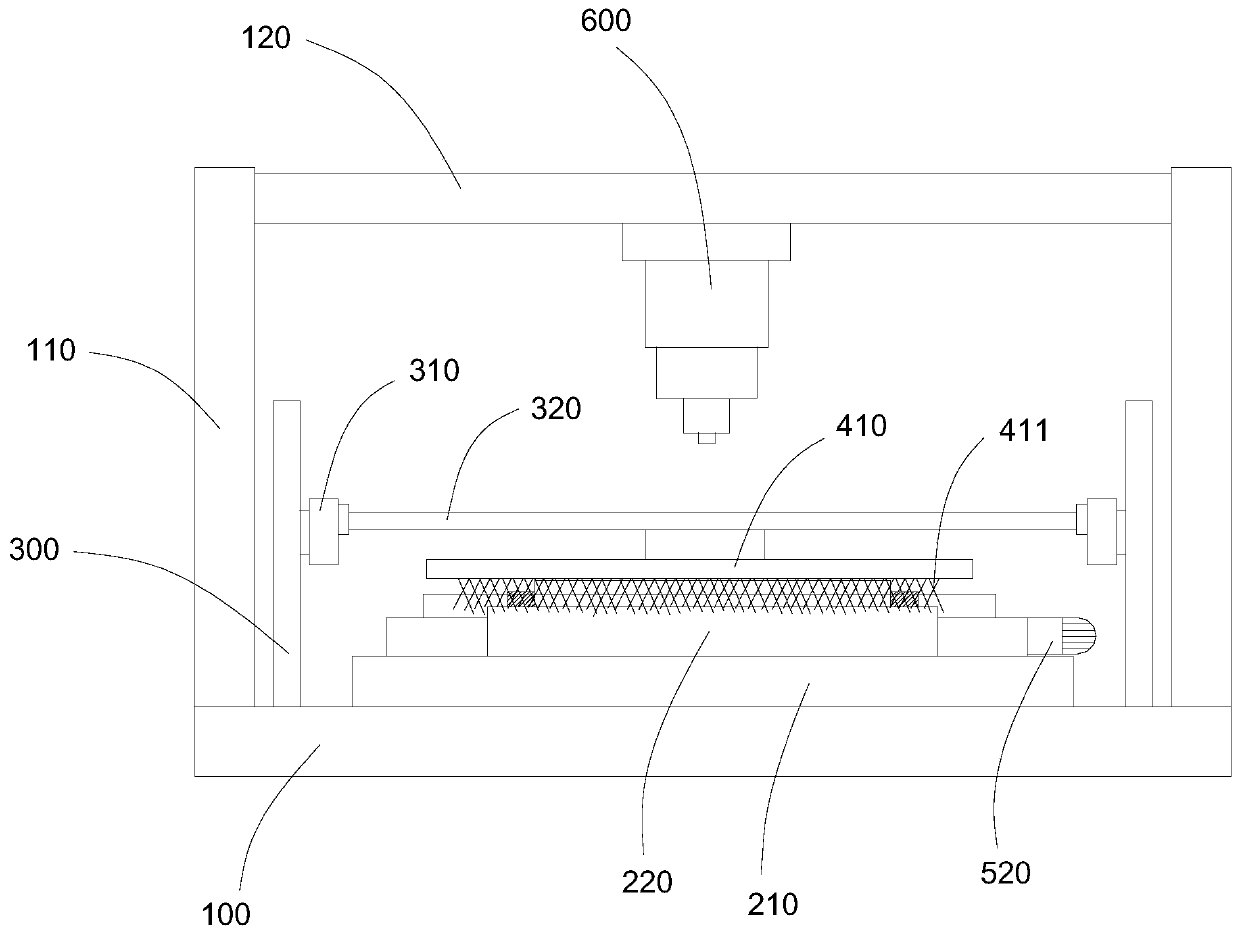

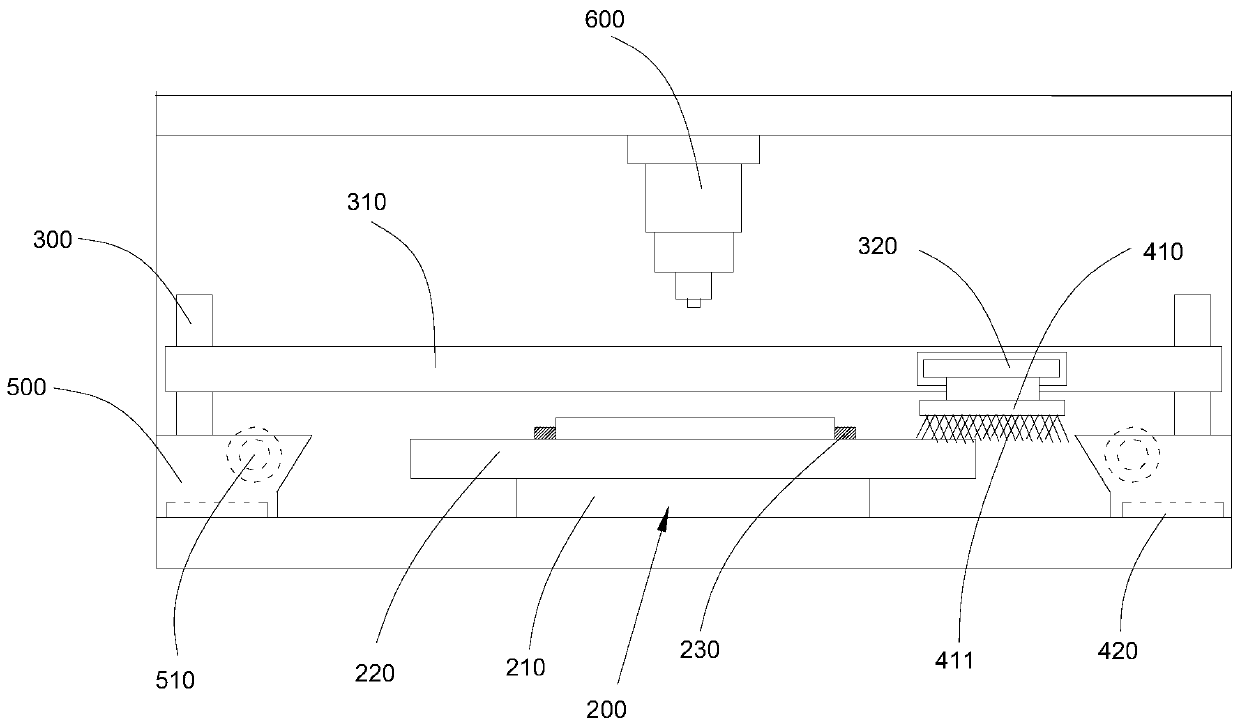

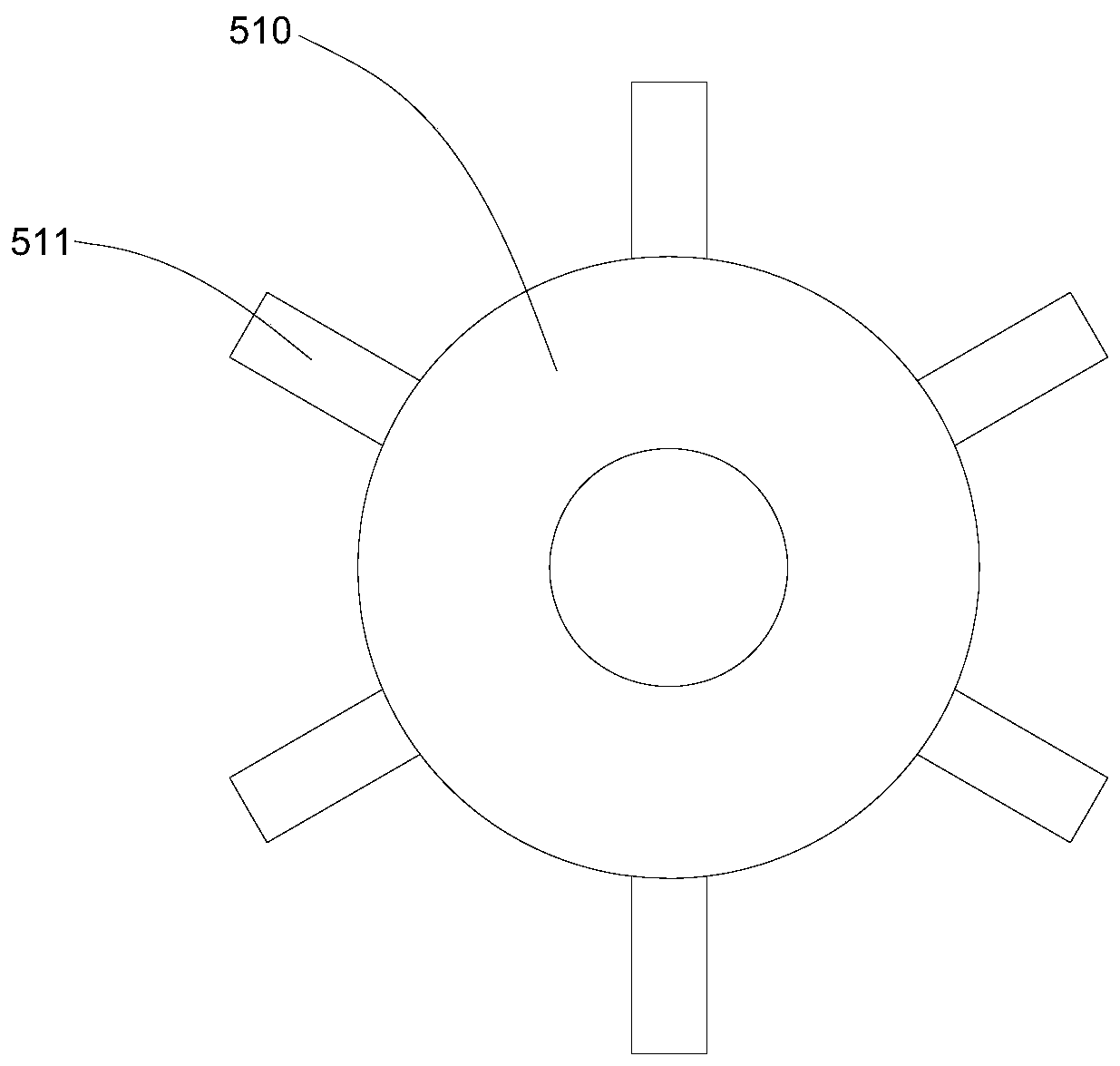

[0019] Such as figure 1 , figure 2 As shown, the specific embodiment of the present invention discloses an ultra-precision horizontal micro-EDM machine tool, which includes a base 100 and a worktable 200 arranged on the base 100. The worktable 200 includes a longitudinally moving platform 210 and A horizontally movable platform 220 is provided on the top surface of the longitudinally movable platform 210. The top surface of the horizontally movable platform 220 is provided with a clamp 230 for fixing the workpiece; the base 100 is provided with two on both sides of the workbench 200 respectively The bracket 300 is provided with a first rodless cylinder 310 between the two brackets 300 on the same side. The two first rodless cylinders 310 are at the same height, and the two slides relative to the first rodless cylinder 310 A seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com