Film sticking device and method for electronic product

A technology of electronic products and film sticking devices, which is applied in the direction of cleaning methods using tools, chemical instruments and methods, cleaning methods and utensils, etc., which can solve the problems of reduced use range, limited specifications of electronic products, and different production specifications of electronic products. , to achieve the effect of improving the cleaning effect and improving the air-drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

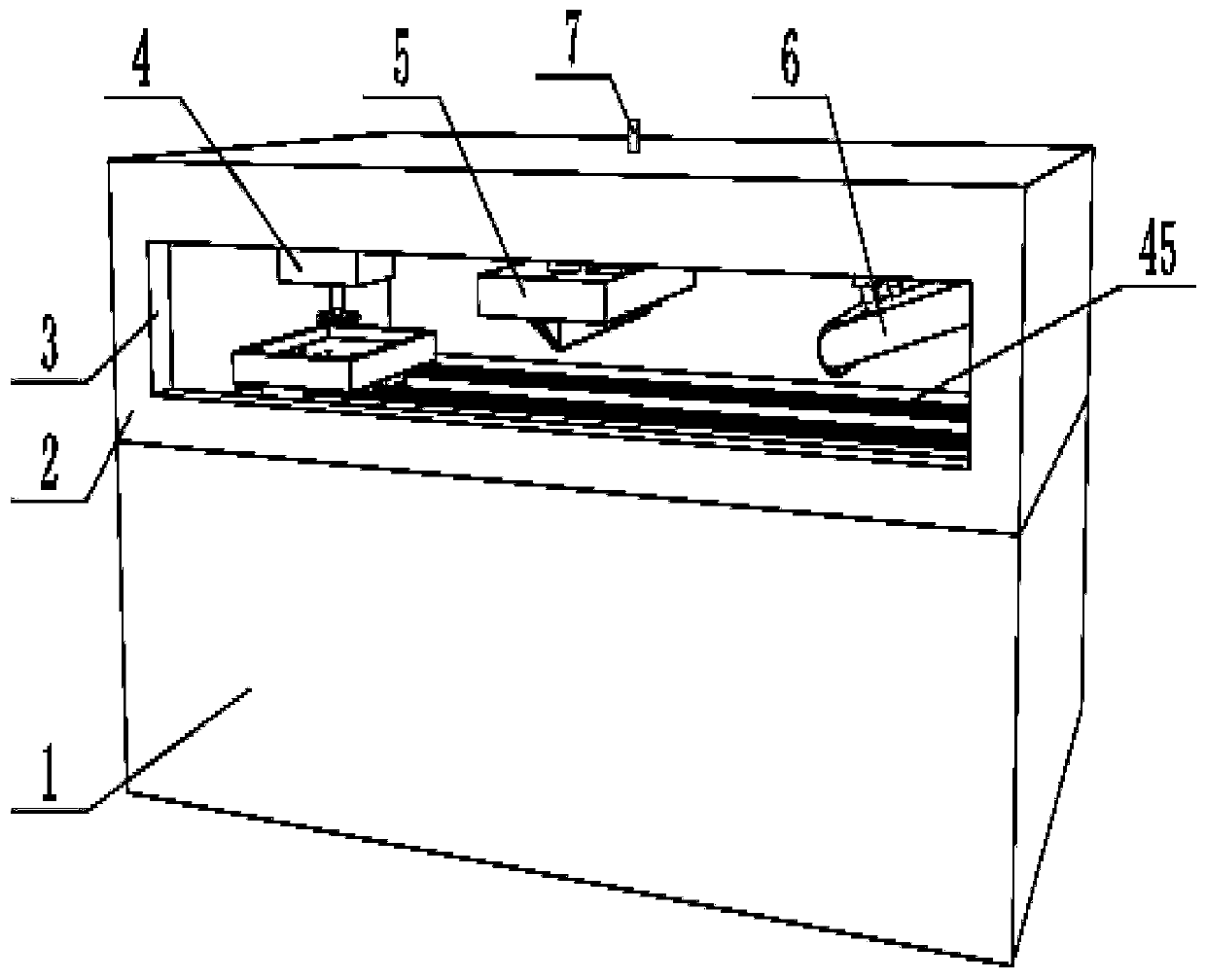

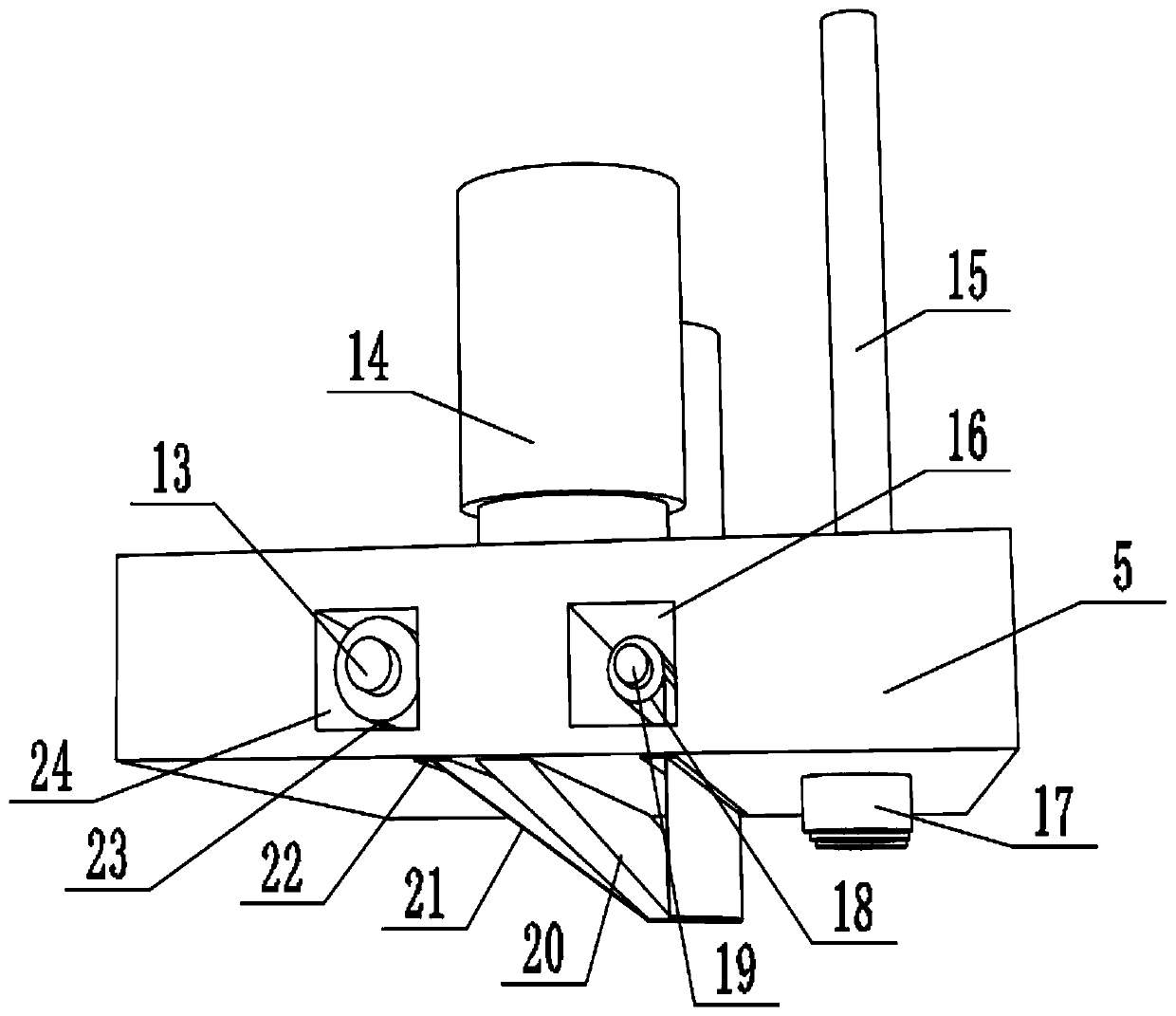

[0033] see Figure 1-6 , in the present invention, a film sticking device for electronic products, such as figure 1As shown, it includes a workbench 1, the outer wall of the top of the workbench 1 is welded with a dustproof box 2, the outer wall of the top of the workbench 1 is provided with a placement mechanism, and the two ends of the inner wall of the top of the dustproof box 2 are respectively provided with a dust removal mechanism and a film pressing mechanism The middle part of the top inner wall of the dustproof box 2 is provided with an air-drying mechanism, and the bottom ends of the outer walls on both sides of the workbench 1 are respectively fixed with a fan box 10 and a negative pressure box 12 by screws, and a negative pressure box 12 is fixed on the inner wall of one side of the negative pressure box 12 by screws. Compressor, the top outer wall of the dustproof box 2 is provided with a gas delivery pipe joint 7.

[0034] For the fixed placement of electronic p...

Embodiment 2

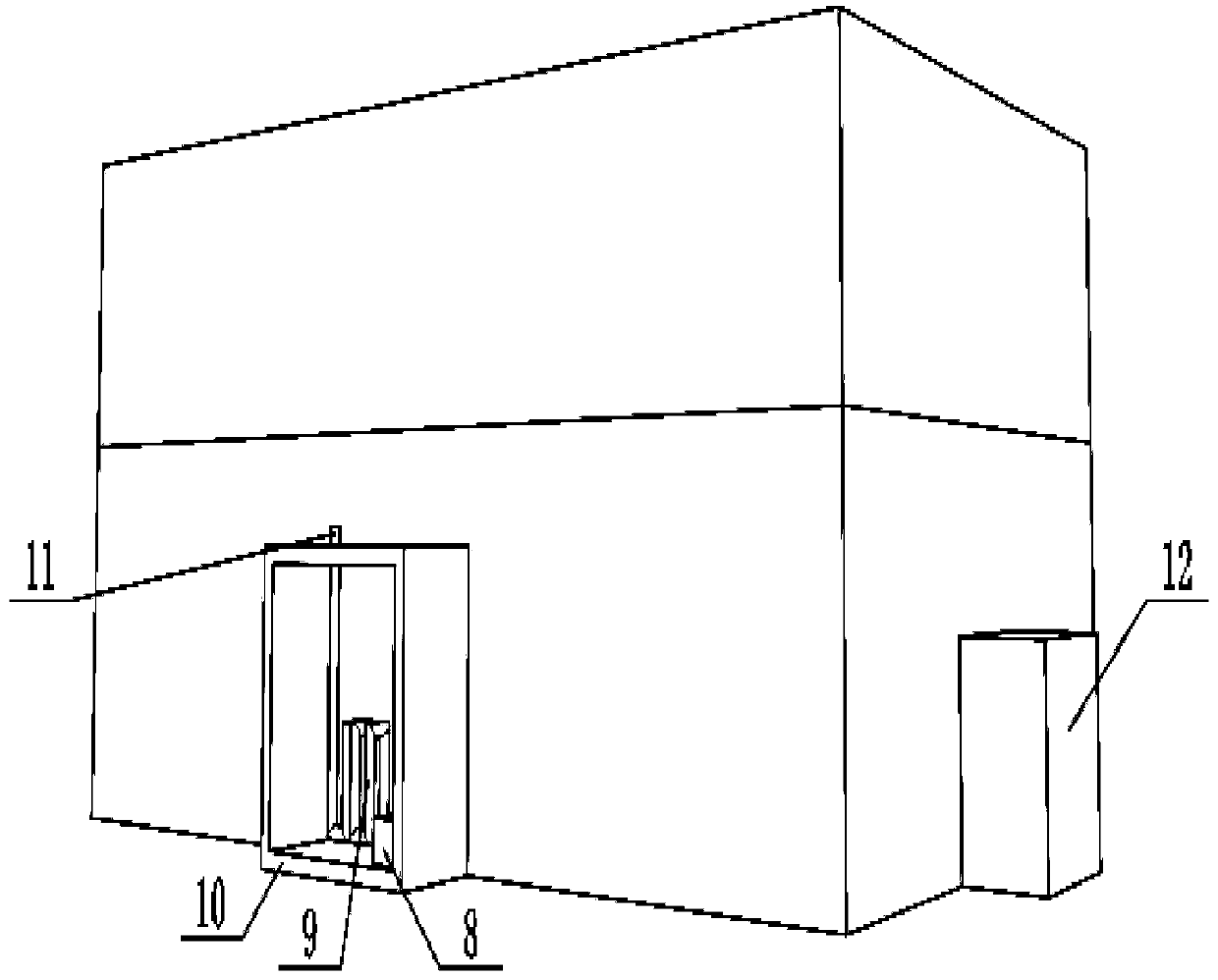

[0039] The difference from Example 1 is: in order to make the water stains on the film surface dry quickly, as figure 2 As shown, one end of the inner wall of the bottom of the fan box 10 is fixed with a fan 8 by a screw, the exhaust end of the fan 8 is provided with a heating pipe 9, one end of the heating pipe 9 is welded with an exhaust interface 11, and the inner wall of the heating pipe 9 is provided with an electric heater. The electric heating wire is heated by electric current, and the fan 8 is started to blow the hot air in the heating tube 9 into the air box 27 through the exhaust port 11, so that the hot air can dry the film surface through the air-drying nozzle 17, improve the air-drying efficiency, and avoid filming at the same time Small dust remaining on the surface will affect the quality of the film.

[0040] A film sticking method of a film sticking device for electronic products, comprising the following steps:

[0041] S1: Connect the device to the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com