Scrap iron cleaning device

A cleaning device and technology for iron filings, applied in cleaning methods and tools, cleaning methods using tools, magnetic separation, etc., can solve the problems of difficult cleaning of iron filings, achieve convenient collection of iron filings, simple maintenance, and improve coating quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

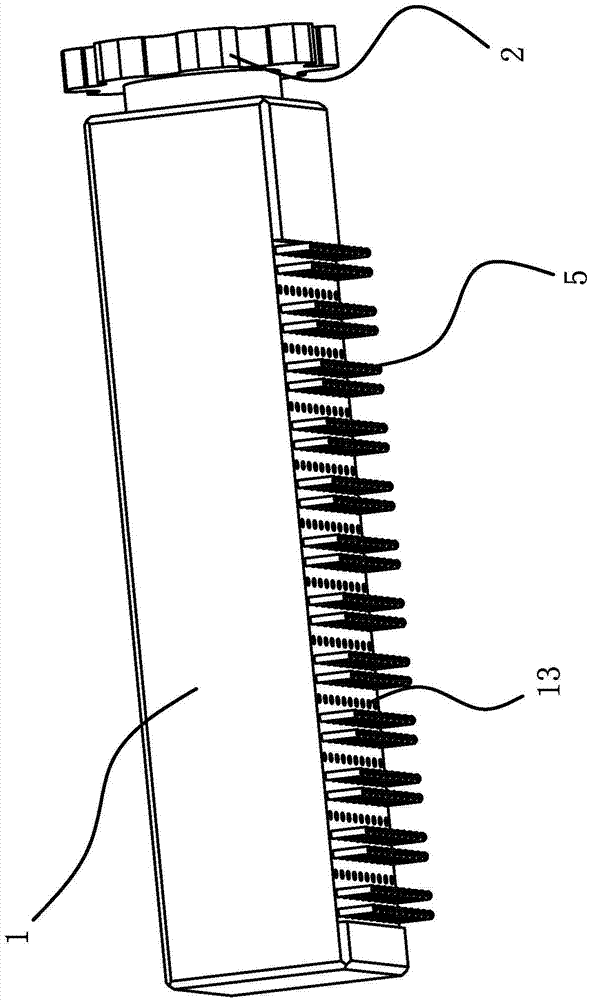

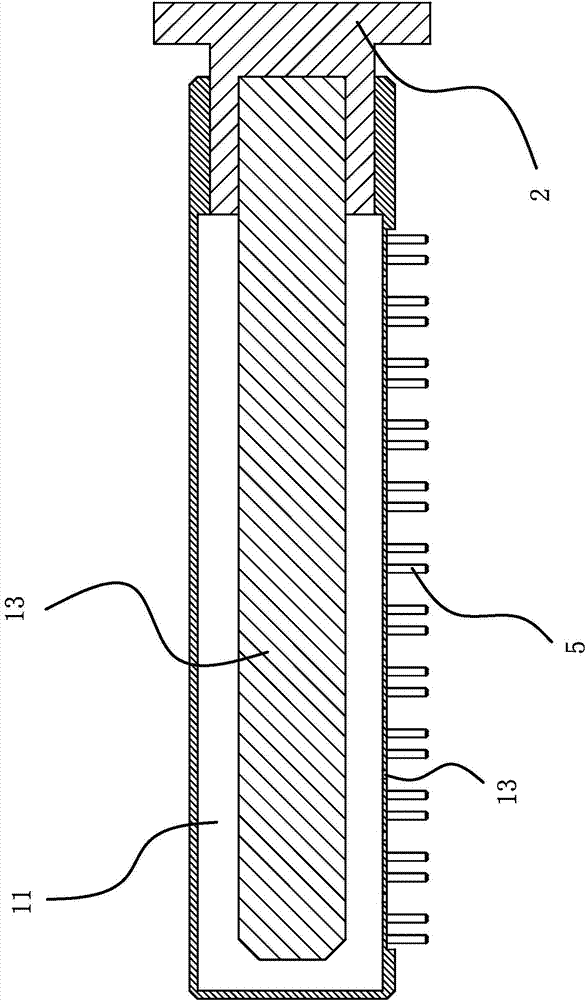

[0031] like figure 1 , figure 2 As shown, the chip cleaning device includes a housing 1 with an inner cavity 11, and the housing 1 is preferably made of plastic or copper. The casing 1 has a working surface, on which brushes 5 capable of cleaning iron filings are fixedly connected, and the brushes 5 can be arranged in a rectangular shape. A number of small holes 13 connecting the inner cavity 11 with the outside world are also opened on the working surface of the casing 1 . The casing 1 is provided with a magnetic assembly capable of sucking iron filings into the inner cavity 11 through the small holes 13 .

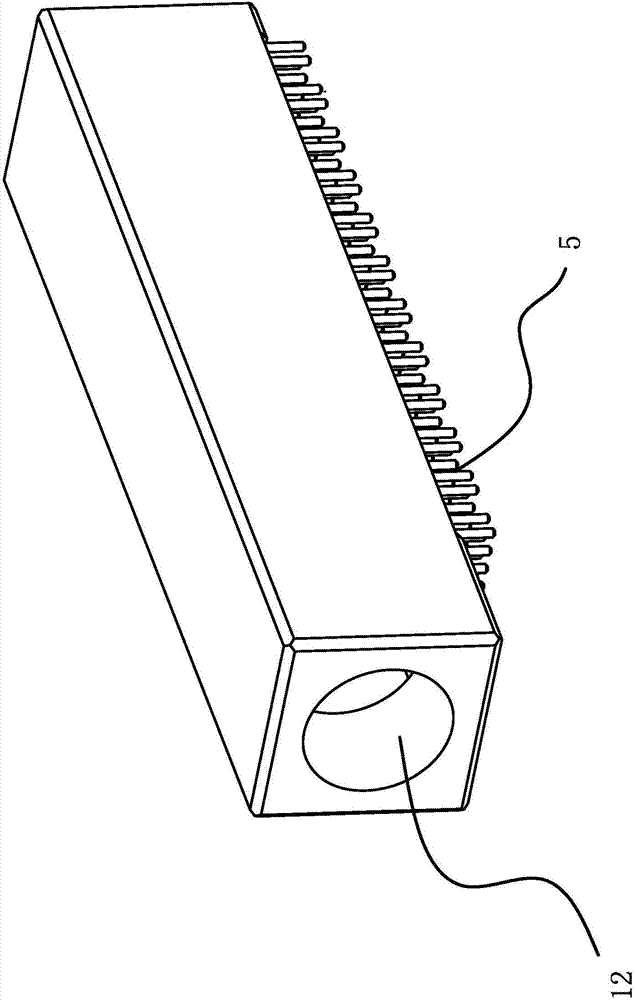

[0032] Specifically, as image 3 , Figure 4 As shown, the shell 1 is in the shape of a long cylinder and has an opening 12 at one end. An end cap 2 sealing the opening 12 is connected at the opening 12, and the end cap 2 is screwed to the shell 1 . The magnetic component is a magnetic rod 3, and the length of the magnetic rod 3 is greater than that of the working su...

Embodiment 2

[0036] like Figure 5 As shown, the structure is the same as that of the housing 1 in Embodiment 1, the difference is that the magnetic assembly in this embodiment is an electromagnet, the electromagnet includes an iron core 4 and a conductive winding that matches its power is wound outside the iron core 4, and the iron The core 4 is placed in the inner cavity 11 . A wire hole is opened on the end cover 2, so that the iron core 4 is conveniently connected to an external power supply through the conductive winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com