Overwater garbage disposal device

A technology for processing device and water garbage, which is applied to circuit devices, battery circuit devices, and open-air water surface cleaning, etc., can solve the problems of high labor consumption, high cost, and safety test for salvage personnel, and achieve the effect of reducing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

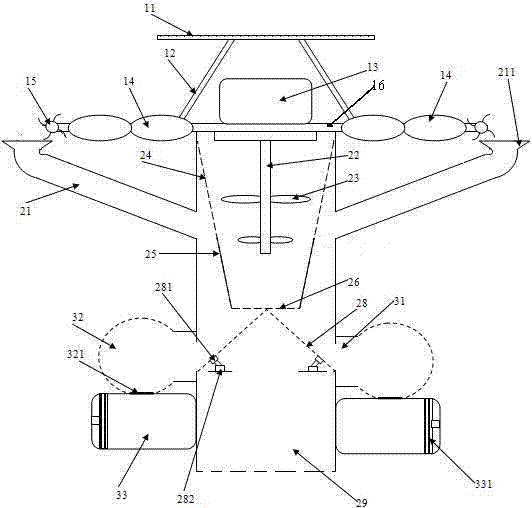

[0029] A waste treatment device on water, comprising a solar panel, a solar panel support, a horizontal main support, a control box, a vertical main channel, a siphon, a garbage collection bag and a garbage shrinking box.

[0030] The transverse main supports are 2 pairs (that is, two transverse supports intersecting with each other, with an angle of 90 degrees), and they are arranged symmetrically with the center as the axis. Oriented solar panel support, a solar panel is installed horizontally on the top of the solar panel support, a vertical main channel is provided at the lower end of the center of the horizontal main support, and an oblique siphon is provided at the middle and upper part of the vertical main channel. The middle and lower part of the passage is provided with a garbage collection bag and a garbage compression box.

[0031] A total of 8 floating airbags are arranged on the side of the transverse main support (such as figure 1 shown), a traveling wheel is ar...

Embodiment 2

[0039] A waste treatment device on water, comprising a solar panel, a solar panel support, a horizontal main support, a control box, a vertical main channel, a siphon, a garbage collection bag and a garbage shrinking box.

[0040]There are 3 horizontal main brackets (the angle between them is 60 degrees), and they are arranged symmetrically with the center as the axis. A control box is arranged at the center of the horizontal main bracket, and an oblique solar panel is arranged on the horizontal main bracket. The bracket is provided with a solar panel horizontally on the top of the solar panel bracket, a vertical main passage is provided at the lower end of the center of the horizontal main support, an oblique siphon is arranged at the middle and upper part of the vertical main passage, and a vertical main passage is arranged at the middle and lower part of the vertical main passage. A garbage collection bag and a garbage compression box are provided.

[0041] Floating airbags...

Embodiment 3

[0050] The working process of embodiment 1 and embodiment 2 water waste treatment device is: according to the situation of specific water body, set the travel route in the control module (such as the size of the lake), charge the battery pack and compare the power generation of the solar panel with the battery pack Electrically connect, inflate the floating airbag to the extent that the inlet of the siphon is 3~5cm below the water surface, and then place the device in a specific water body. The rotation of the travel wheel makes the device travel in the water body in a specific zigzag form. The rotation of the rotating shaft drives the rotating blades to rotate, and a vortex is formed in the inner channel to make the water flow down along the main channel, so that a negative pressure is formed inside and adsorbed into the siphon tube. The water on the water surface, including garbage floating on the water surface, is sucked by the siphon tube Entering the main channel, due to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com