Automatic cleaning device for photovoltaic plates

A technology for automatic cleaning and cleaning devices, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as high labor consumption, save water, increase power generation, and save operations cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

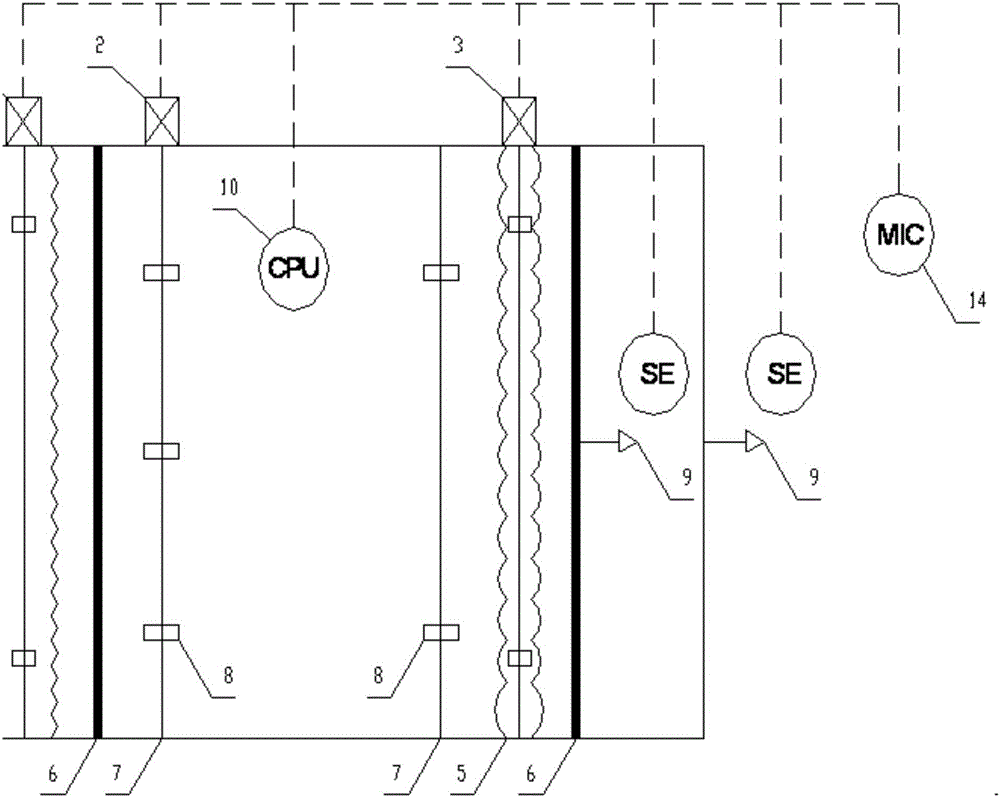

[0020] like Figure 1-2 As shown, the photovoltaic panel automatic cleaning device of this embodiment includes a frame 13 and a running device, a cleaning device and a control device arranged on the frame 13;

[0021] The running device includes an active running device and a passive running device; the active running device includes a traveling driving device 1, a traveling transmission shaft 7 and an active traveling wheel 8 arranged on the traveling transmission shaft 7; the passive traveling device includes a traveling transmission The shaft 7 and the passive travel wheel 8 arranged on the travel transmission shaft 7; the travel transmission shaft 7 of the passive travel device and the travel transmission shaft 7 of the active travel device are arranged in parallel at intervals;

[0022] The cleaning device includes at least one cleaning mechanism; the cleaning mechanism includes cleaning drive mechanisms 1, 3, cleaning brushes 4, 5 and atomizing flushers 6; The cleaning ...

Embodiment 2

[0026] On the basis of the above embodiments, the cleaning device of this embodiment includes two cleaning mechanisms, one of which is a rough cleaning mechanism, and the other cleaning mechanism is a fine cleaning mechanism, and the hardness of the bristles of the fine cleaning mechanism is lower than that of the The bristle hardness of the coarse cleaning mechanism.

[0027] The photovoltaic panel automatic cleaning device of the present embodiment includes two cleaning mechanisms, and wherein the hardness of the bristles of the fine cleaning mechanism is lower than the hardness of the bristles of the rough cleaning mechanism, and water is sprayed from the atomizing flusher 6 to On the surface of the battery board, the dust attached to the surface of the battery board is washed away, and the cleaning brushes 4 and 5 for the initial cleaning use high-speed rotation to wipe and throw off the attached water droplets and dust, and then the atomizing flusher 6 performs flushing an...

Embodiment 3

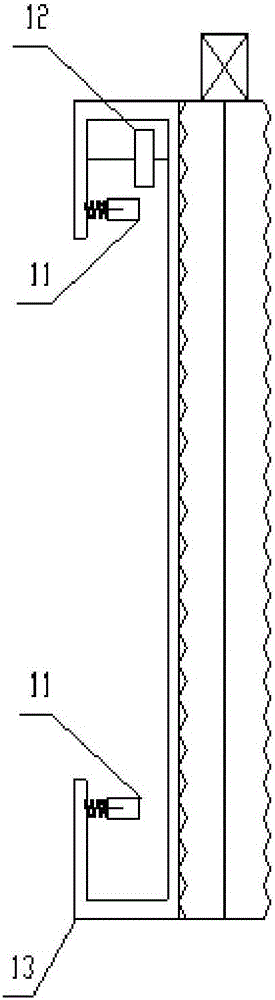

[0029] On the basis of the above embodiments, spring clamping wheels 11 for clamping the edge of the battery panel and longitudinal guide wheels 12 for guiding are provided on both sides of the frame 13 .

[0030] The spring clamping wheel 11 and the longitudinal guide wheel 12 provided on the frame 13 can fix the moving route of the frame 13, that is, ensure that the frame 13 moves along the direction in which the battery panels are arranged, and the frame 13 will not break away from the battery panels, which can ensure Equipment Security.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com