Water-based organic ceramic sprayed aluminum veneer and manufacturing technology thereof

A manufacturing process and aluminum veneer technology, which is applied in the field of water-based organic porcelain spraying aluminum veneer and its manufacturing process, can solve the problems of high surface condition requirements and complicated procedures, achieve excellent self-cleaning function, ensure high temperature resistance, Adds protective and decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

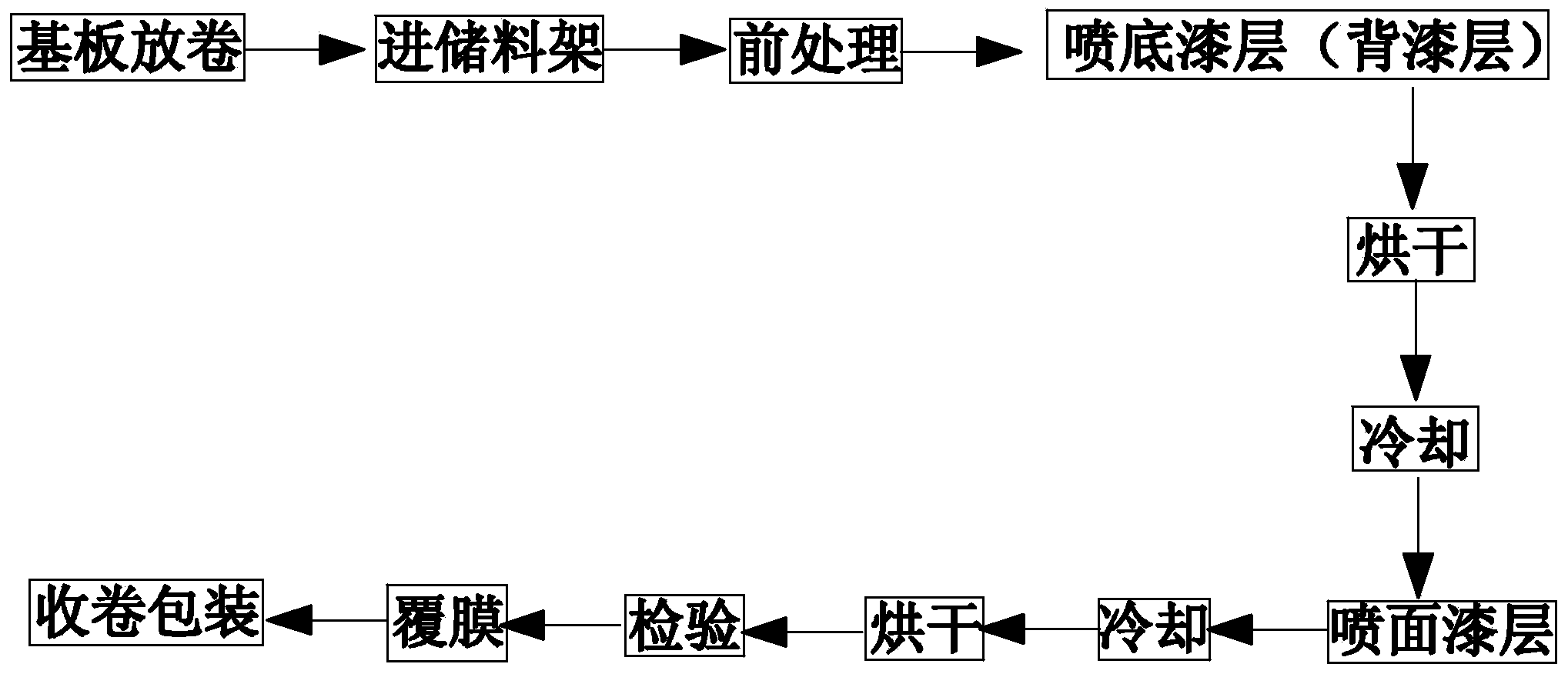

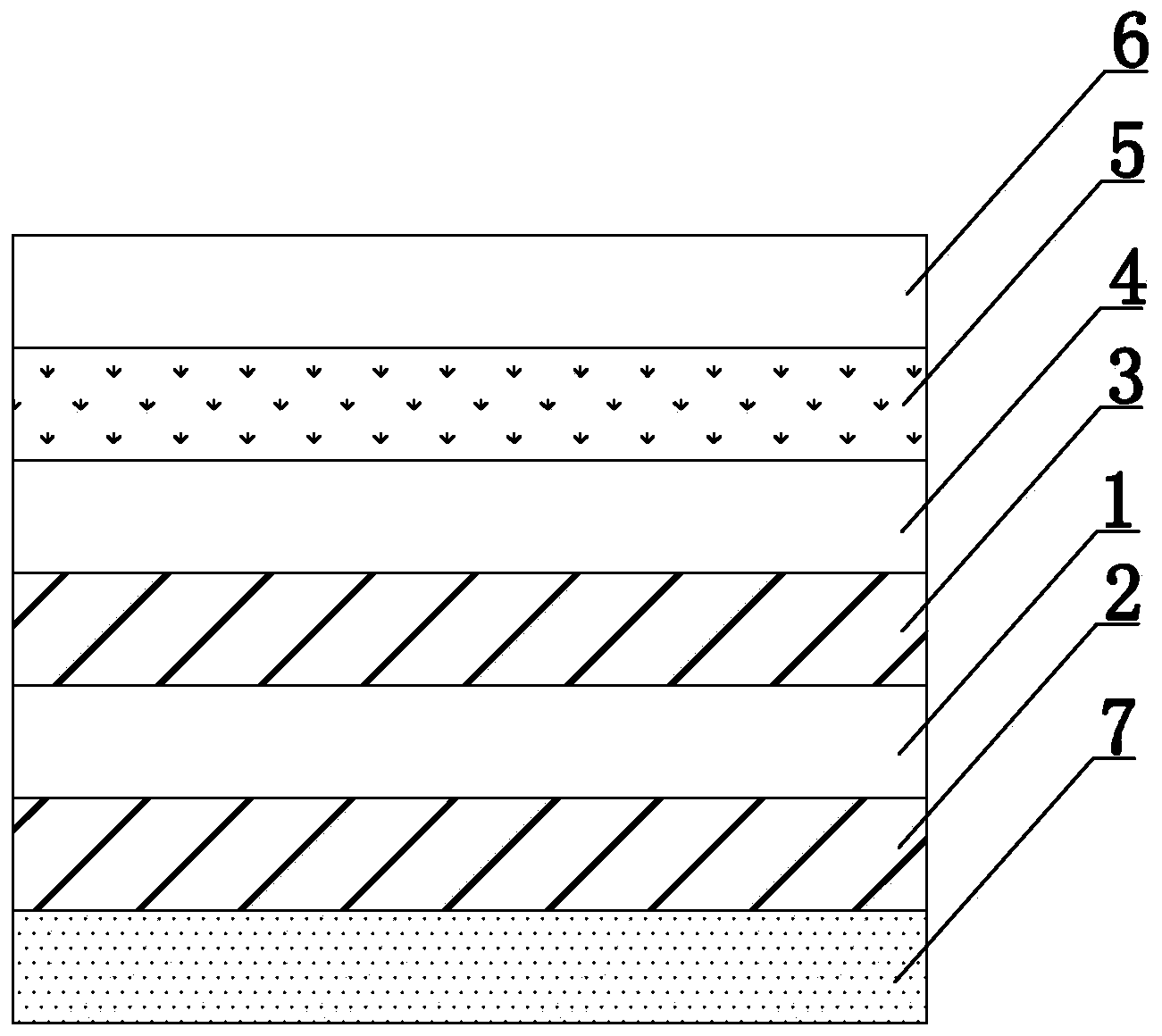

[0032] This embodiment is a water-based organic porcelain sprayed aluminum veneer and its manufacturing process, combined with figure 1 and image 3, choose 3.0mm thickness of 3003H24 grade aluminum veneer as the aluminum substrate 1, after pickling, water washing, pre-treatment respectively on the bottom surface and surface of the aluminum substrate 1 to form a passivation layer 2 and a passivation layer 2 3, in the passivation layer The viscosity of the spraying on the first 2 is set at 20-40 seconds according to the characteristics of the water-based paint, and the polyester back paint with a film thickness of 6-10 μm is used as the anti-rust layer. At the same time, the viscosity of the spraying on the passivation layer 23 is set at 10-30 Seconds, water-based pure white paint with a film thickness of 10-20 μm, the spraying line speed is set at 1.5-2m / min, the back paint layer 7 and the primer layer 4 are formed by 60°C preheating section for 10 minutes, and the volatile wa...

Embodiment 2

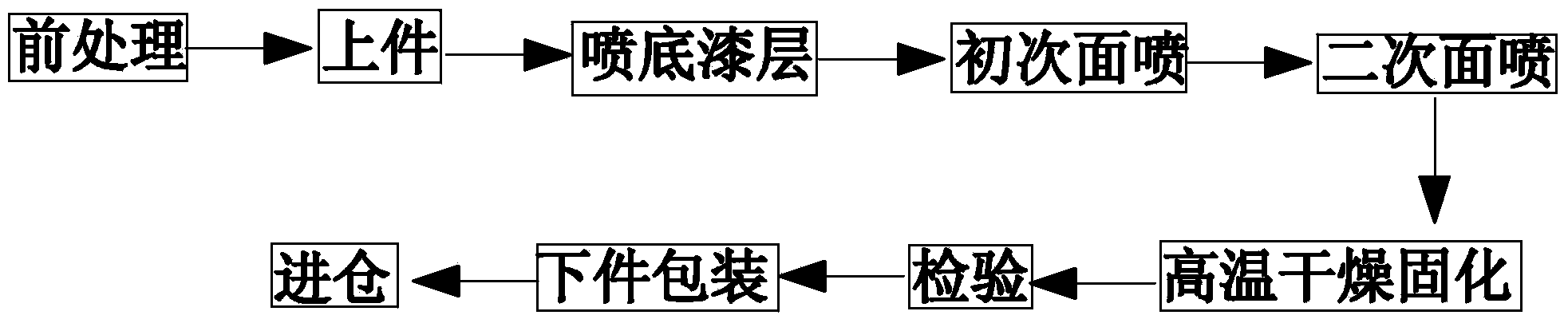

[0037] In this embodiment, a water-based organic porcelain sprayed aluminum veneer and its manufacturing process are combined figure 2 and image 3 , select 2.0mm thick aluminum veneer of 3003H24 grade as the aluminum substrate 1, after pickling, water washing, and pretreatment, passivation layer 1 and passivation layer 2 and 3 are formed on the bottom and surface of the aluminum substrate 1 respectively, and the passivation layer 2.3 The spraying construction viscosity is set to 10~30s according to the characteristics of the water-based paint, and the thickness of the water-based pure white paint is 10-20μm. The spraying line speed is set to 1.5-2m / min, and it is leveled and volatilized after 10 minutes of pre-heating at 60°C. Moisture forms primer layer 4; select silver water-based organic porcelain topcoat, and spray 20~30μm in the surface spray booth (the construction viscosity is set to 10~30s according to the characteristics of the water-based paint, and the line speed ...

Embodiment 3

[0042] In this embodiment, a water-based organic porcelain sprayed aluminum veneer and its manufacturing process are combined figure 2 and image 3 , select an aluminum veneer with a thickness of 3.0 mm and a grade of 3004H24 as the aluminum substrate 1, and form a passivation layer 1 and a passivation layer 2 on the bottom and surface of the aluminum substrate 1 after pickling, water washing, and pretreatment; The spraying construction on layer 2 and 3 is a water-based pure white background paint whose viscosity is set to 15-30s according to the characteristics of the water-based paint, and the thickness is 10-15μm. Leveling and volatile water form the primer layer 4; select high-gloss yellow water-based organic porcelain topcoat, and complete the 20~30μm topcoat spraying in the surface spray booth. (In order to make the paint surface uniform and the water solvent to be fully pre-volatilized, the topcoat is sprayed twice, and the first thinner topcoat is evenly sprayed (pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com