Feed forming device

A molding device and feed technology, which is applied in the direction of feed, raw material extrusion granulation, mixer, etc., can solve the problems of adverse effects of processing, easy overflow of dust, easy adhesion of residues, etc., to improve self-cleaning ability, improve sealing effect, The effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

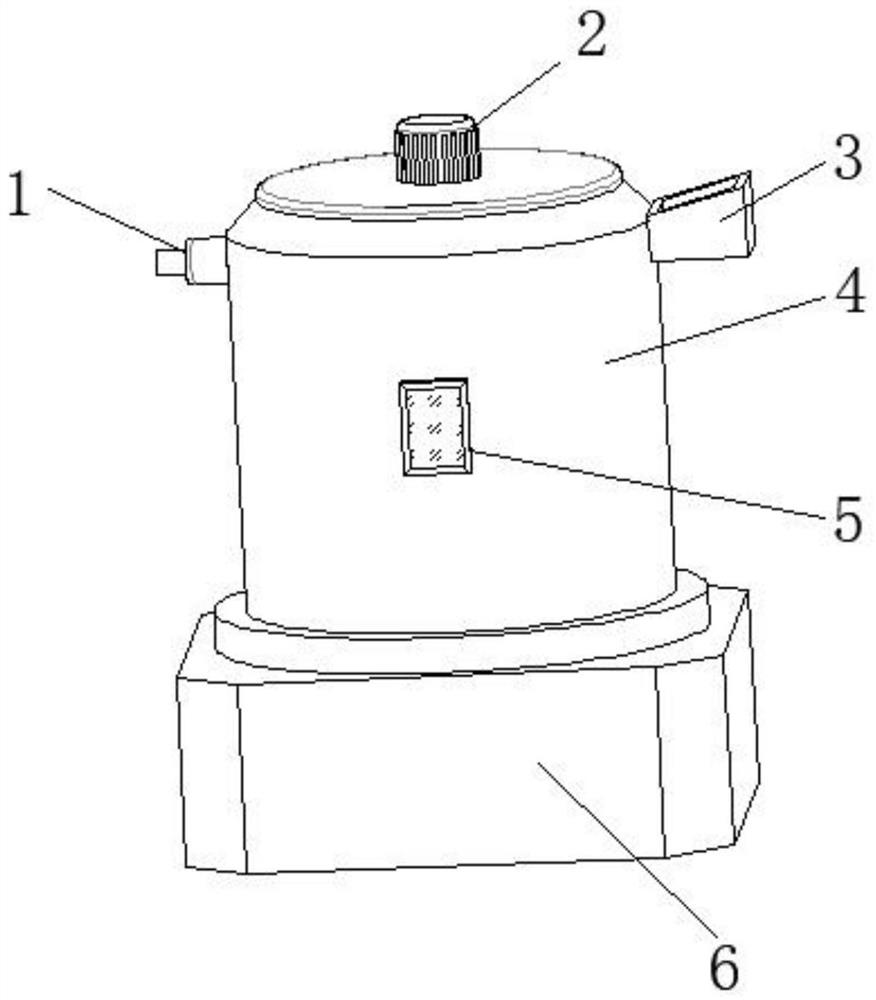

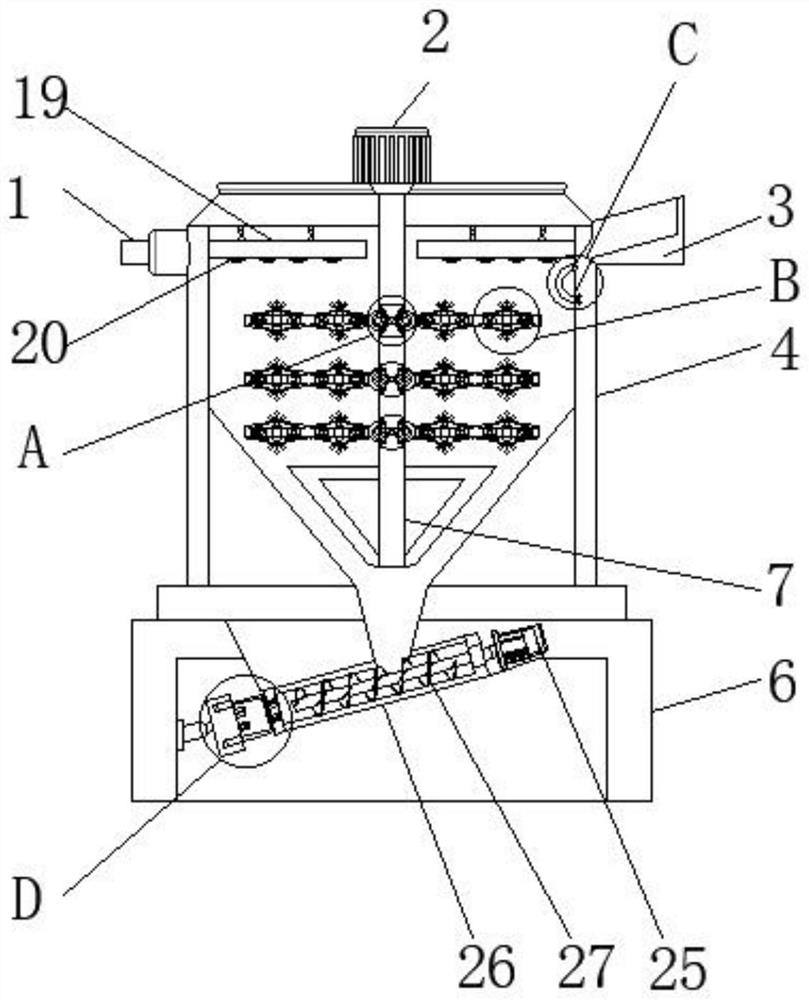

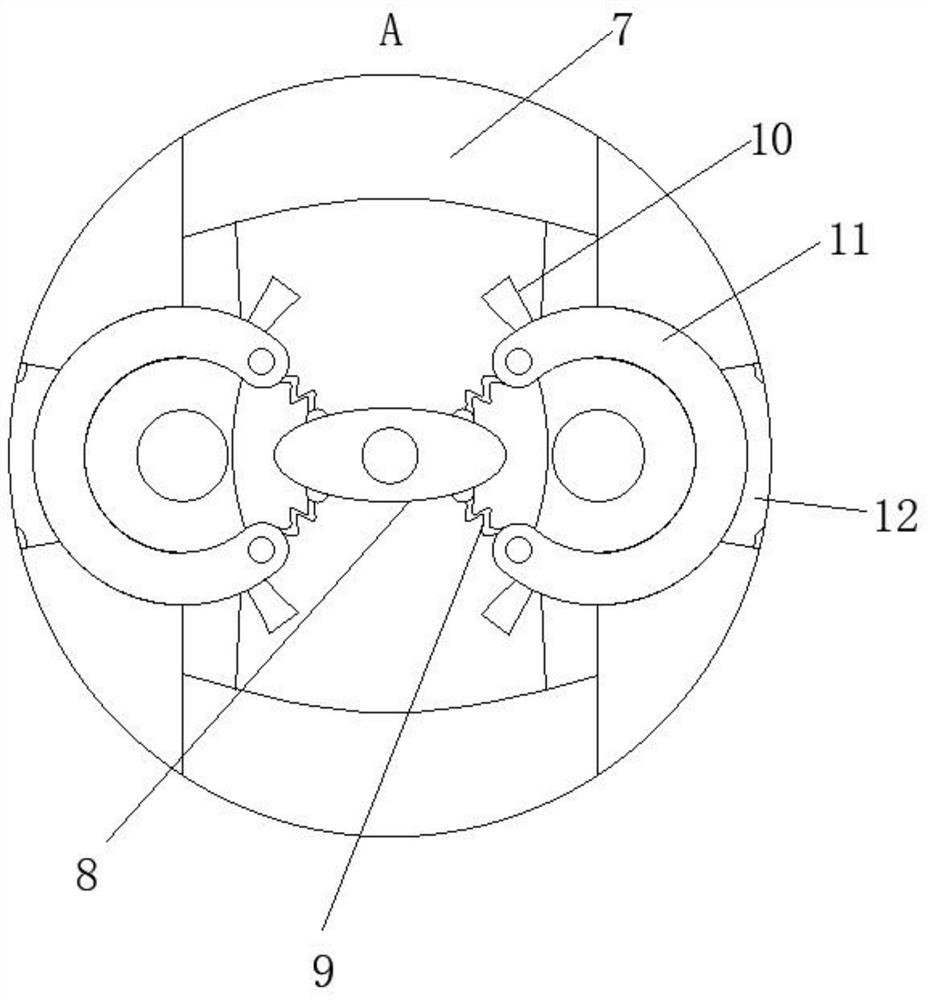

[0031] Such as Figure 1-7As shown, the embodiment of the present invention provides a feed forming device, including a water inlet pipe 1, a rotating motor 2, a feed hopper 3, a processing tank 4, a control panel 5 and a fixing seat 6, and the rotating motor 2 is arranged on the top of the processing tank 4 On the outer wall, the output shaft of the rotating motor 2 is connected to the rotating shaft 7 through a coupling, the outer wall of the rotating shaft 7 is provided with a stirring mechanism, and the outer wall at one end of the processing tank 4 is provided with a water inlet pipe 1, which communicates with the external water delivery mechanism , the other side outer wall of the processing tank 4 is provided with a feed hopper 3, the control panel 5 is arranged on the outer wall of the processing tank 4, the fixing seat 6 is arranged on the bottom outer wall of the processing tank 4, and the bottom inner wall of the fixing seat 6 is provided with a molding mechanism. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com