Antibacterial polycarbonate composite and preparation method and application thereof

A composite material and polycarbonate technology, applied in the field of antibacterial polycarbonate composite materials and their preparation, can solve the problems of poor material durability, loss of sterilization function, and increased material cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

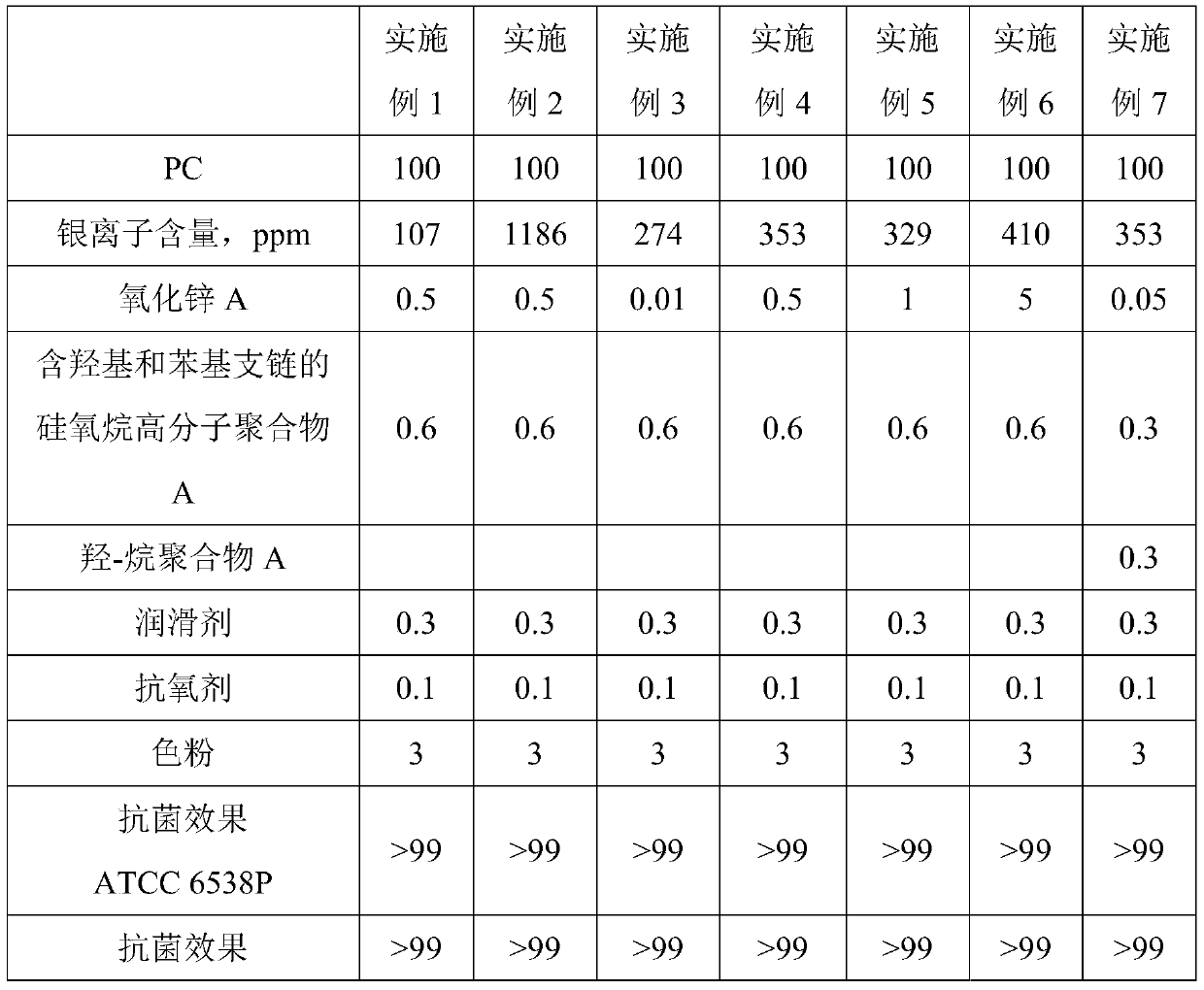

Examples

Embodiment 22

[0113] Example 22 The preparation method of antibacterial polycarbonate composite material: polycarbonate, nanometer metal oxides, siloxane polymers with hydroxyl and alkyl branched chains, silver ion antibacterial agents, and antioxidants were added according to the proportioning ratio. Mix evenly in a high mixer, then add to a twin-screw extruder, melt and mix at a temperature of 240°C-260°C, then granulate, cool, and dry to obtain an antibacterial polycarbonate composite material.

[0114] Examples 17-22 Examples 23-30 and Comparative Examples 7-10 The preparation method of antibacterial polycarbonate composite materials: according to the proportion, the siloxane polymers with hydroxyl and alkyl branches are sprayed onto the nano metal oxide Form a coating layer on the surface of the object, and then mix it with polycarbonate, silver ion antibacterial agent, and antioxidant in a high-speed mixer, and then add it to a twin-screw extruder. Melt and mix, then granulate, cool a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com