Preparation method of polylactic acid material with anti-adhesion and sterilization functions

A polylactic acid material, anti-adhesion technology, applied in polyester coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve the problems that PLA has no bactericidal performance and cannot meet the requirements, and achieves broad-spectrum and long-term Effective antifouling and antibacterial function, good antibacterial durability, good biocompatibility and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

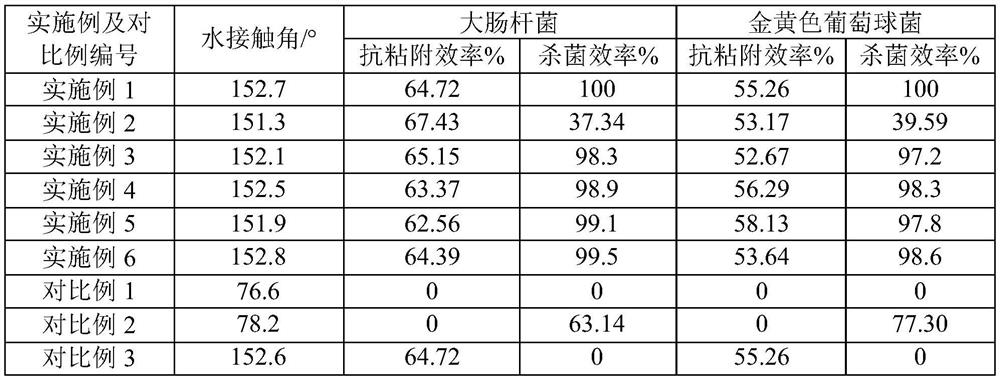

Embodiment 1

[0034] A kind of preparation method of the polylactic acid material with anti-adhesion sterilization function, comprises the following steps:

[0035] (1) 1.2g polylactic acid is dissolved in 24mL methylene chloride, obtains polylactic acid solution, then adds 30mL poor solvent (dehydrated alcohol: n-butanol: butyl acetate volume ratio is 1:1: 1) mixed evenly to obtain a coating solution;

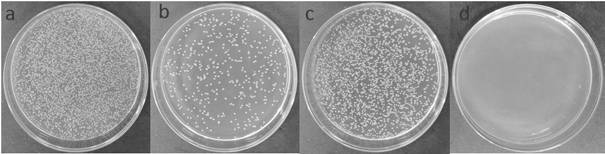

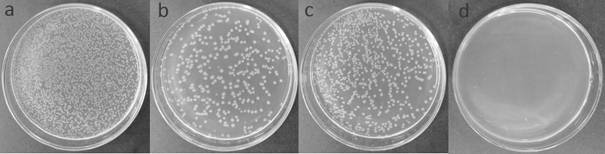

[0036] (2) The coating solution that step (1) obtains is drip-coated on the polylactic acid sheet substrate that thickness is 2mm, and the coating solution on the unit area is 0.3mL / cm 2 , after drying in an oven at 40°C for 48 hours, the surface of the polylactic acid pattern was peeled off using a biaxially oriented polypropylene tape to obtain a superhydrophobic surface;

[0037] (3) Dissolve chlorophyll A in ethanol, sonicate for 3 minutes to prepare a chlorophyll solution with a concentration of 1 μmol / L, and drop-coat the chlorophyll solution onto the superhydrophobic surface obtaine...

Embodiment 2

[0039] A kind of preparation method of the polylactic acid material with anti-adhesion sterilization function, comprises the following steps:

[0040](1) 1.2g polylactic acid is dissolved in 24mL methylene chloride, obtains polylactic acid solution, then adds 30mL poor solvent (dehydrated alcohol: n-butanol: butyl acetate volume ratio is 1:1: 1) mixed evenly to obtain a coating solution;

[0041] (2) The coating solution that step (1) obtains is drip-coated on the polylactic acid sheet substrate that thickness is 2mm, and the coating solution on the unit area is 0.3mL / cm 2 , after drying in an oven at 40°C for 48 hours, the surface of the polylactic acid pattern was peeled off using a biaxially oriented polypropylene tape to obtain a superhydrophobic surface;

[0042] (3) Dissolve chlorophyll A in ethanol, sonicate for 3 minutes to prepare a chlorophyll solution with a concentration of 0.5 μmol / L, and drop-coat the chlorophyll solution onto the superhydrophobic surface obtain...

Embodiment 3

[0044] A kind of preparation method of the polylactic acid material with anti-adhesion sterilization function, comprises the following steps:

[0045] (1) 1.2g polylactic acid is dissolved in 24mL methylene chloride, obtains polylactic acid solution, then adds 30mL poor solvent (dehydrated alcohol: n-butanol: butyl acetate volume ratio is 1:1: 1) mixed evenly to obtain a coating solution;

[0046] (2) The coating solution that step (1) obtains is drip-coated on the polylactic acid sheet substrate that thickness is 2mm, and the coating solution on the unit area is 0.3mL / cm 2 , after drying in an oven at 40°C for 48 hours, the surface of the polylactic acid pattern was peeled off using a biaxially oriented polypropylene tape to obtain a superhydrophobic surface;

[0047] (3) Dissolve chlorophyll A in ethanol, sonicate for 3 minutes to prepare a chlorophyll solution with a concentration of 2 μmol / L, and drop-coat the chlorophyll solution onto the superhydrophobic surface obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com