Polyquaternium polymer emulsion antibacterial agent, preparation method thereof and application thereof

A technology of polymer emulsion and antibacterial agent, which is applied in the field of polyquaternium polymer emulsion antibacterial agent and its preparation, can solve the problems of difficulty in controlling the degree of halogenation, loss of small molecules, high toxicity, etc., and achieve high antibacterial rate, Reduced impact, good antibacterial durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

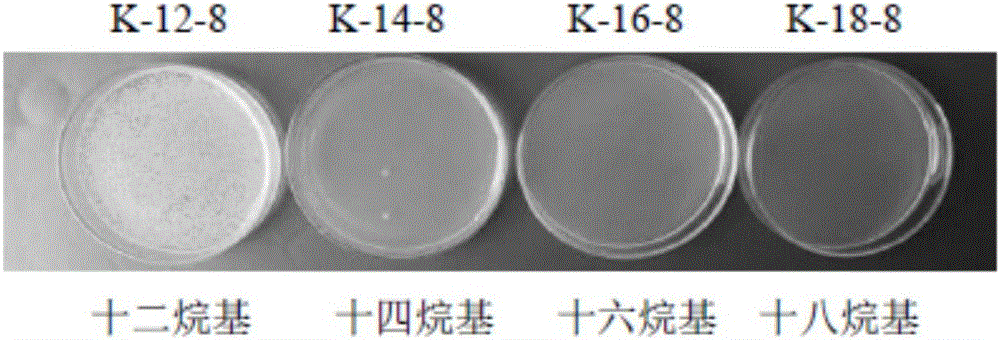

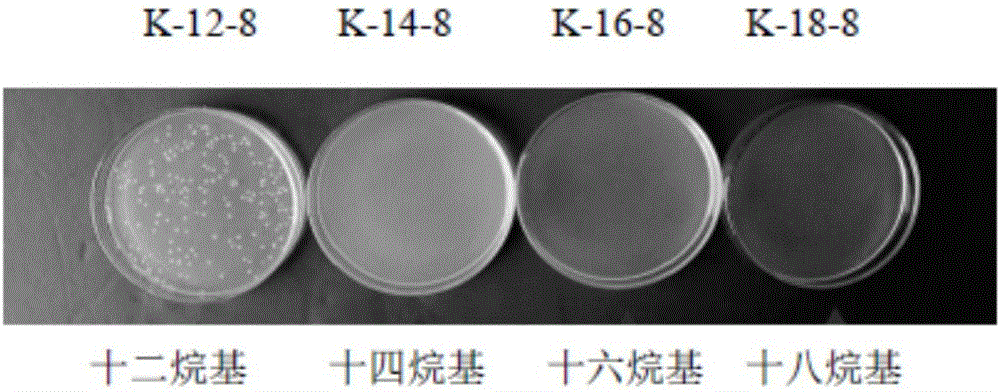

[0048] The preparation method of polyquaternium polymer emulsion antibacterial agent (K-12-8, K-14-8, K-16-8, K-18-8) of different structures:

[0049] (1) In 4 groups of reaction kettles, add 1.92 parts by mass of cationic antibacterial monomers of different structures (dodecyldimethylpropenyl ammonium chloride cationic antibacterial monomer, tetradecyldimethylpropenyl chloride Ammonium chloride cationic antibacterial monomer, hexadecyl dimethyl propylene ammonium chloride cationic antibacterial monomer, octadecyl dimethyl propylene ammonium chloride cationic antibacterial monomer) and 70 mass parts of water and 0.5 mass parts The initiator 2,2'-azobisisobutylamidine dihydrochloride. Add dodecyl dimethyl acryl ammonium chloride cationic antibacterial monomer, tetradecyl dimethyl acryl ammonium chloride cationic antibacterial monomer, hexadecyl dimethyl acryl ammonium chloride cationic antibacterial Reactors for monomers are sequentially marked as 1K, 2K, 3K, and 4K.

[0050...

Embodiment 2

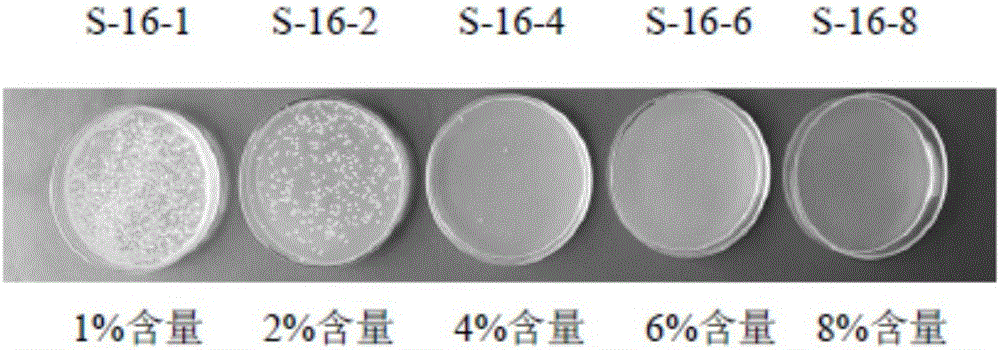

[0053] A preparation method of cetyl antibacterial emulsion: different mass percentages (respectively 1%, 2%, 4%, 6%, 8%, accounting for the content of total acrylic acid monomers, that is, based on all acrylic acid monomers The polyquaternium polymer emulsion antibacterial agent (S-16-1, S-16-2, S-16 -4, S-16-6, S-16-8) preparation method:

[0054] (1) In 5 groups of reactors, add respectively 0.24 mass parts, 0.48 mass parts, 0.96 mass parts, 1.44 mass parts, 1.92 mass parts of cationic antibacterial monomers (hexadecyl dimethylpropenyl chloride) of the same structure ammonium chloride cationic antibacterial monomer) and the initiator azodicyanovaleric acid of 70 mass parts water and 0.5 mass part. The reaction kettles in which 0.24 parts by mass, 0.48 parts by mass, 0.96 parts by mass, 1.44 parts by mass, and 1.92 parts by mass of cationic antibacterial monomers were added were respectively recorded as 1S, 2S, 3S, 4S, and 5S.

[0055] (2) In 5 groups of feeding kettles, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com