Co-extrusion composite aluminum foil film and preparation method thereof

A technology of co-extrusion composite, aluminum foil film, applied in the field of packaging, can solve the problems of poor partition performance of aluminum foil packaging bags, affecting product function and life, difficult to meet packaging requirements, etc. Strong protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

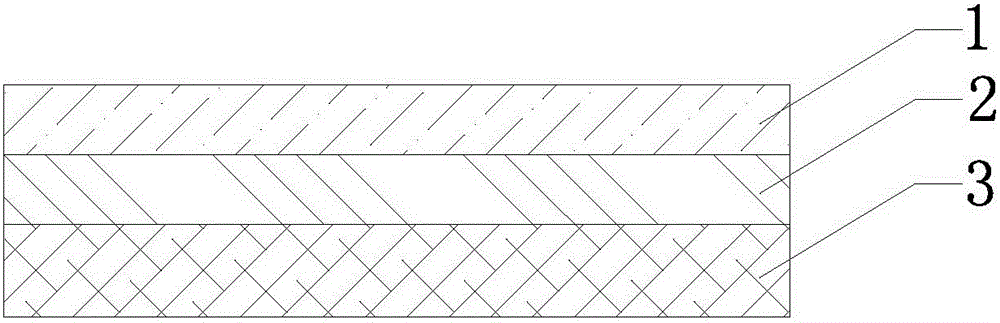

[0046] See Figure 1-3 , a co-extruded composite aluminum foil film, the co-extruded composite aluminum foil film comprises a surface layer 1, a middle layer 2 and a substrate layer 3 arranged sequentially from outside to inside, the upper surface of the middle layer 2 is attached to the lower surface of the surface layer 1, The lower surface of the middle layer 2 is attached to the upper surface of the base layer 3, the surface layer 1 is a PET protective film or PA protective film, the middle layer 2 is an aluminum foil film, the base layer 3 is a multi-layer co-extrusion film, and the outer surface of the surface layer 1 The surface is laminated with an antistatic coating.

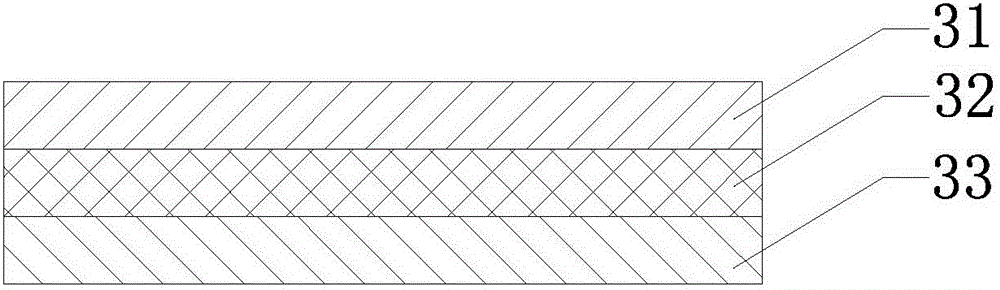

[0047] In this embodiment, the multi-layer co-extrusion film is a three-layer co-extrusion film, and the three-layer co-extrusion film includes a nylon layer 31, an adhesive resin layer 32 and a polyethylene layer 33 that are laminated sequentially from outside to inside, such as figure 2 shown; or, t...

Embodiment 2

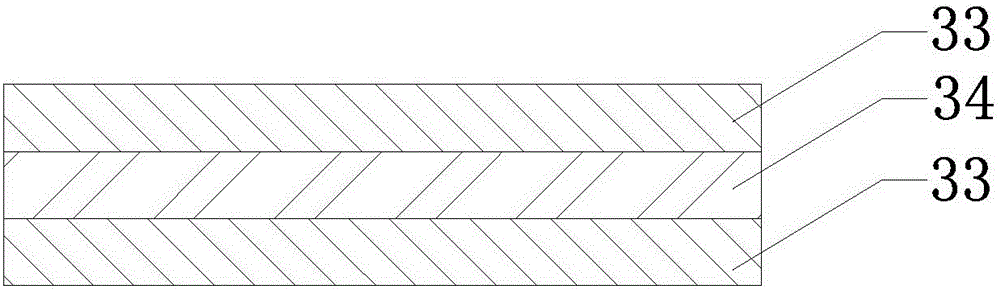

[0049] See Figure 4-5 , The difference between this embodiment and the first embodiment is that the multi-layer co-extrusion film is a five-layer co-extrusion film, and the five-layer co-extrusion film includes a polyethylene layer 33, an adhesive resin, and Layer 32, nylon layer 31, adhesive resin layer 32 and polyethylene layer 33, such as Figure 4 or, the five-layer co-extruded film includes a polyethylene layer 33, an adhesive resin layer 32, an ethylene-vinyl alcohol copolymer layer 35, an adhesive resin layer 32, and a polyethylene layer 33 that are laminated sequentially from outside to inside, such as Figure 5 shown. The five-layer co-extruded film of the present invention can also be realized in other ways, and any obvious replacements are within the protection scope of the present invention without departing from the concept of the present invention.

Embodiment 3

[0051] See Figure 6-9 , The difference between this embodiment and the first embodiment is that the multi-layer co-extrusion film is a seven-layer co-extrusion film, and the seven-layer co-extrusion film includes a nylon layer 31, an adhesive resin layer, and an adhesive resin layer that are laminated sequentially from outside to inside 32, polyethylene layer 33, adhesive resin layer 32, nylon layer 31, adhesive resin layer 32 and polyethylene layer 33, such as Figure 6 or, the seven-layer co-extruded film comprises polyethylene layer 33, adhesive resin layer 32, nylon layer 31, adhesive resin layer 32, nylon layer 31, adhesive resin layer 32 and poly Vinyl layer 33, such as Figure 7 shown; or, the seven-layer co-extrusion film includes a polyethylene layer 33, an adhesive resin layer 32, a nylon layer 31, an ethylene-vinyl alcohol copolymer layer 35, a nylon layer 31, and an adhesive resin layer laminated sequentially from outside to inside 32 and polyethylene layer 33, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com