Rare earth cerium doped copper-zinc composite oxide as well as preparation method and application of rare earth cerium doped copper-zinc composite oxide

A technology of composite oxides and rare earth cerium, which is applied in the fields of botany equipment and methods, chemical instruments and methods, applications, etc., and can solve problems such as limitations in application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 0.005mol copper nitrate (Cu(NO 3 ) 2 , Molecular weight: 187.56), 0.0001mol cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O, molecular weight: 434.12), 0.0949mol zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, molecular weight: 297.49) and 0.12mol citric acid (C 6 H 8 O 7 , Molecular weight: 192.14); configure 200ml of a 1:1 mixed solution of water:ethanol, use this mixed solution as a solvent, add zinc nitrate, copper nitrate, cerium nitrate and citric acid to the solvent, and ultrasonically disperse at room temperature for 20 minutes to obtain Stable, uniform and transparent sol; in a water bath at 80°C, the sol is coagulated under magnetic stirring to obtain a gel, aged at room temperature for 10 hours, and then placed in an oven, dehydrated, dried and ground at 80°C to obtain a precursor powder ; The precursor powder is heat treated at 500° C. to obtain Ce-CuO-ZnO doped with rare earth cerium, containing 5.00 mol% Cu and 0.10 mol% Ce.

[0025] The obtained copper-zinc composite oxide Ce-C...

Embodiment 2

[0028] Example 2 (comparative example)

[0029] Weigh 0.005mol copper nitrate (Cu(NO 3 ) 2 , Molecular weight: 187.56), 0.095mol zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, molecular weight: 297.49) and 0.12mol citric acid (C 6 H 8 O 7 , Molecular weight: 192.14); configure 200ml of a mixed solution with a volume ratio of water: ethanol of 1:1, use this mixed solution as a solvent to dissolve the above-mentioned drugs under the action of ultrasound, and ultrasound for 20 minutes at room temperature to obtain a stable, uniform and transparent sol; In a water bath at 80°C, the colloidal solution was coagulated under magnetic stirring to obtain a gel. The gel was aged for 10 hours at room temperature, and then placed in an oven, dehydrated, dried, and ground at 80°C to obtain precursor powder; Heat treatment at ℃ to obtain copper-zinc oxide (CuO-ZnO) not doped with rare earth cerium.

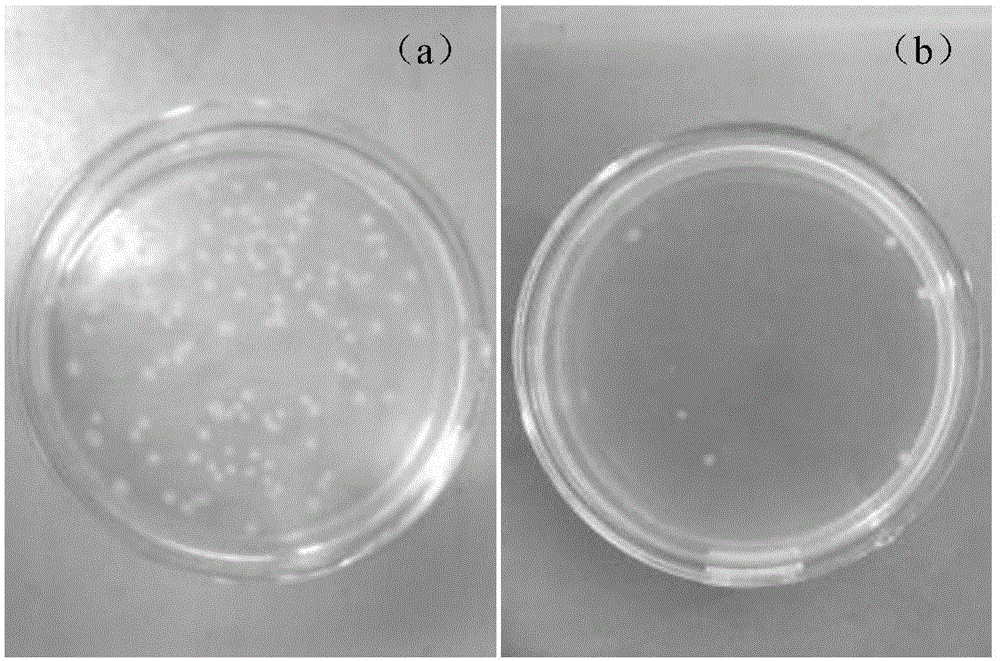

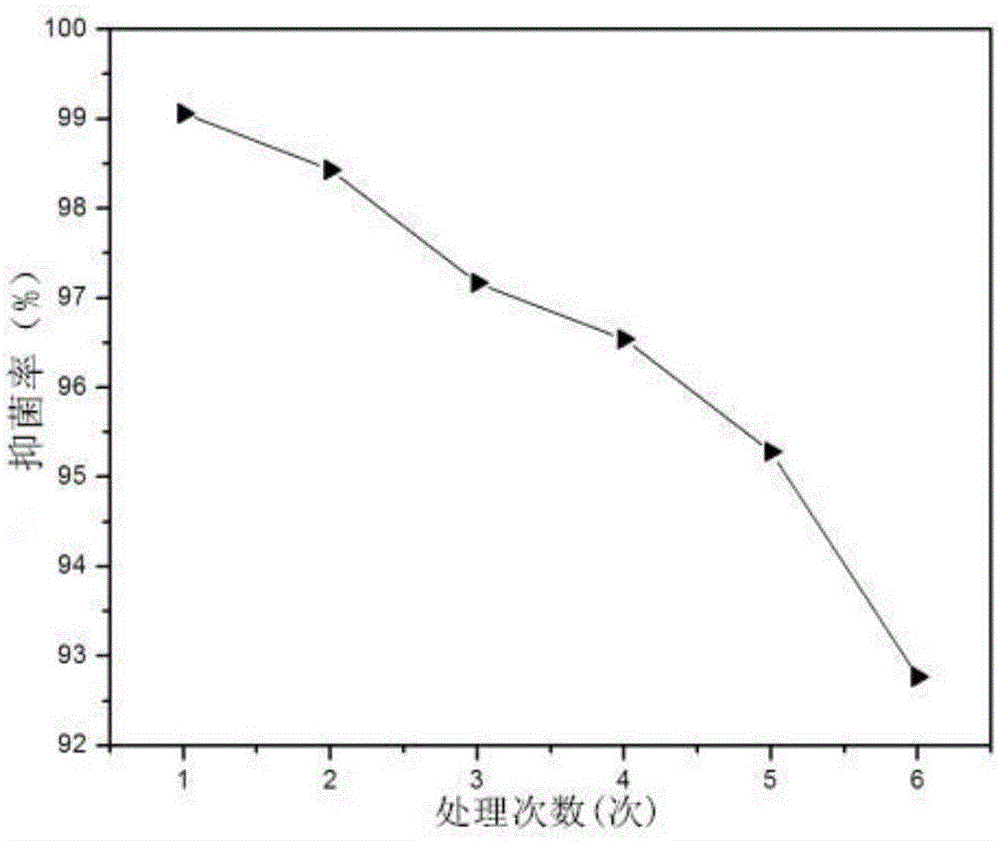

[0030] In order to study the antibacterial rate of Ce-CuO-ZnO, the present invention adopts the sterilization...

Embodiment 3

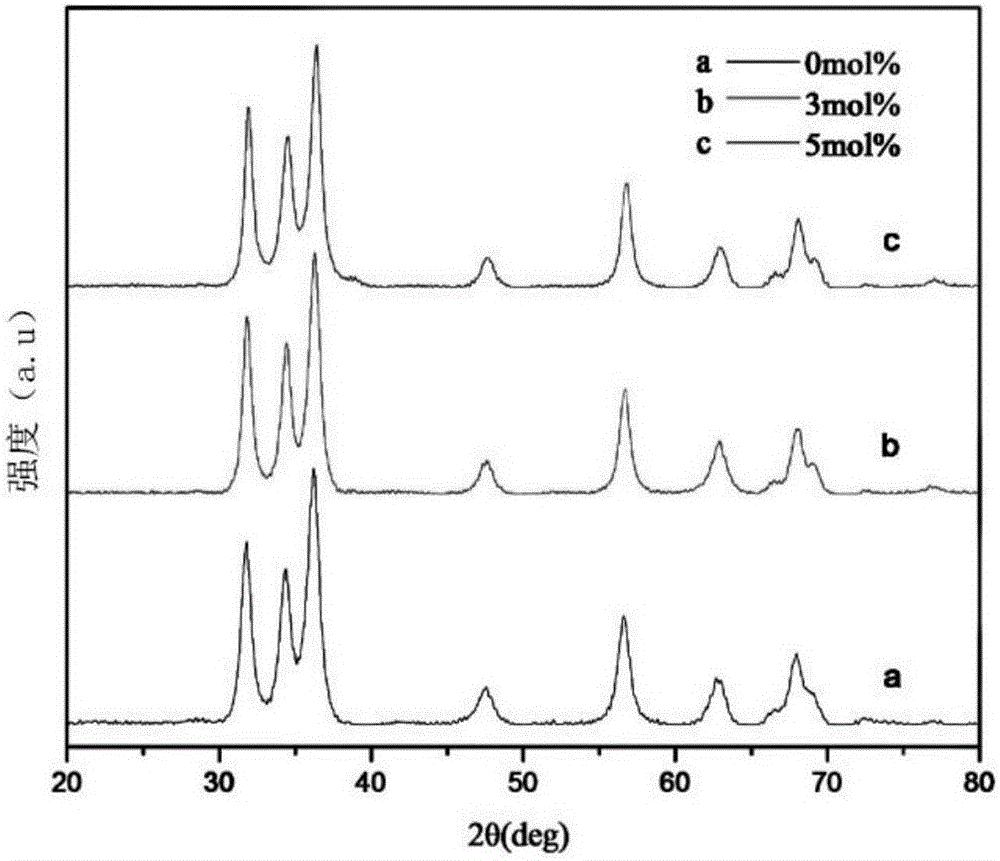

[0035] According to the preparation steps described in Example 1, the amount of chemical agents was changed, and 0.003 mol of copper nitrate (Cu(NO 3 ) 2 , Molecular weight: 187.56), 0.0001mol cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O, molecular weight: 434.12), 0.0969mol zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, molecular weight: 297.49) and 0.12mol citric acid (C 6 H 8 O 7 , Molecular weight: 192.14). Prepare Ce-CuO-ZnO doped with rare earth cerium containing 3.00 mol% Cu and 0.10 mol% Ce.

[0036] According to the preparation steps described in Example 1, the amount of chemical agent was changed, and 0.0001 mol of cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O, molecular weight: 434.12), 0.0999mol zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, molecular weight: 297.49) and 0.12mol citric acid (C 6 H 8 O 7 , Molecular weight: 192.14). Ce-ZnO doped with rare earth cerium containing 0.10 mol% Ce was prepared.

[0037] The two materials obtained in the foregoing Example 3 were combined with the rare earth cerium-doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com