Clothing degerming liquid and preparation method thereof

A technology for sterilizing liquid and clothing, applied in the directions of botanical equipment and methods, chemicals for biological control, fungicides, etc., can solve the problem of short effectiveness, low killing efficiency, and clothing that does not have continuous sterilization and antibacterial effect. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

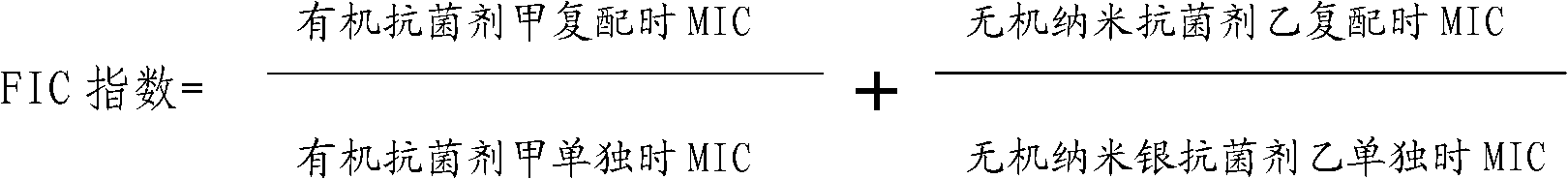

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] Embodiment 1: the preparation of clothing sterilization liquid of the present invention

[0144] Its preparation steps are as follows:

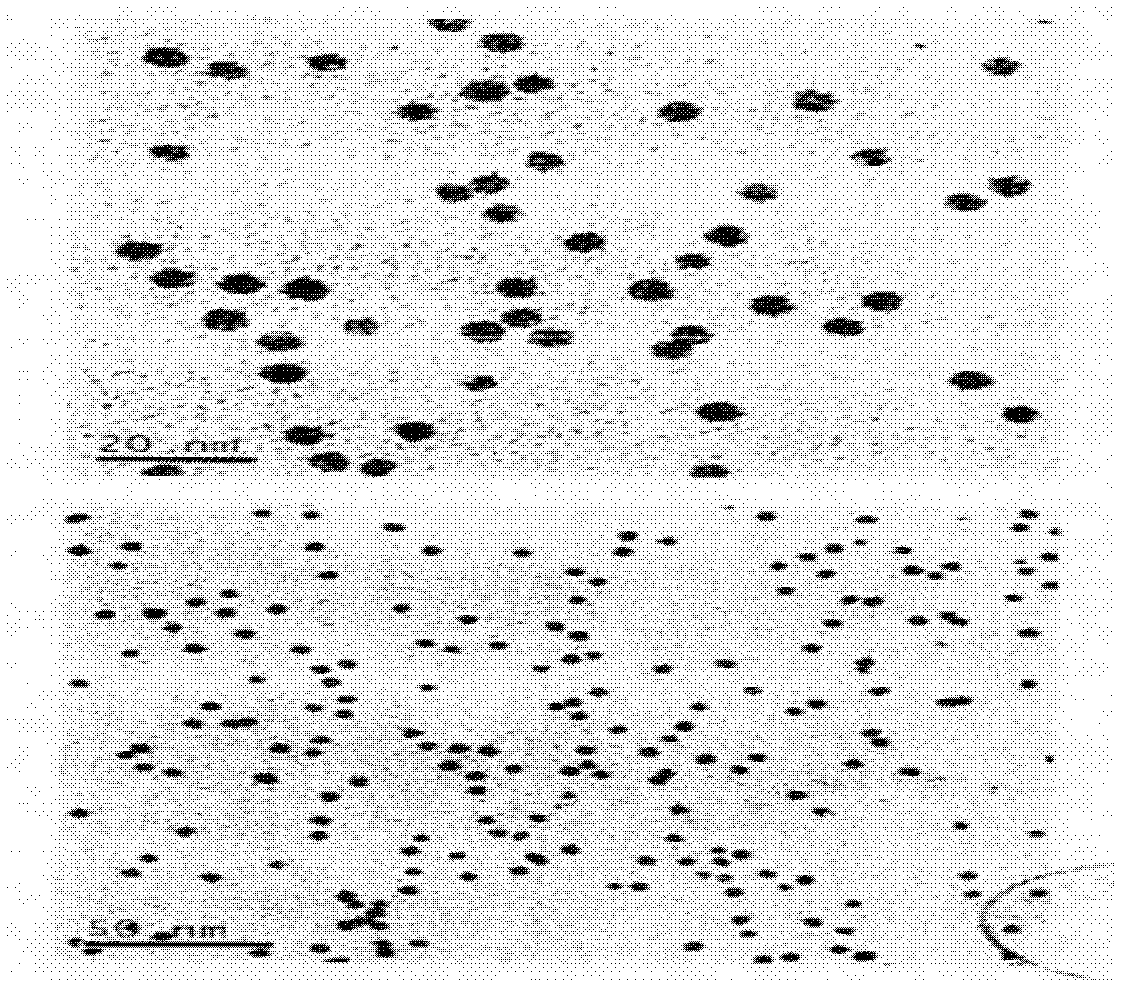

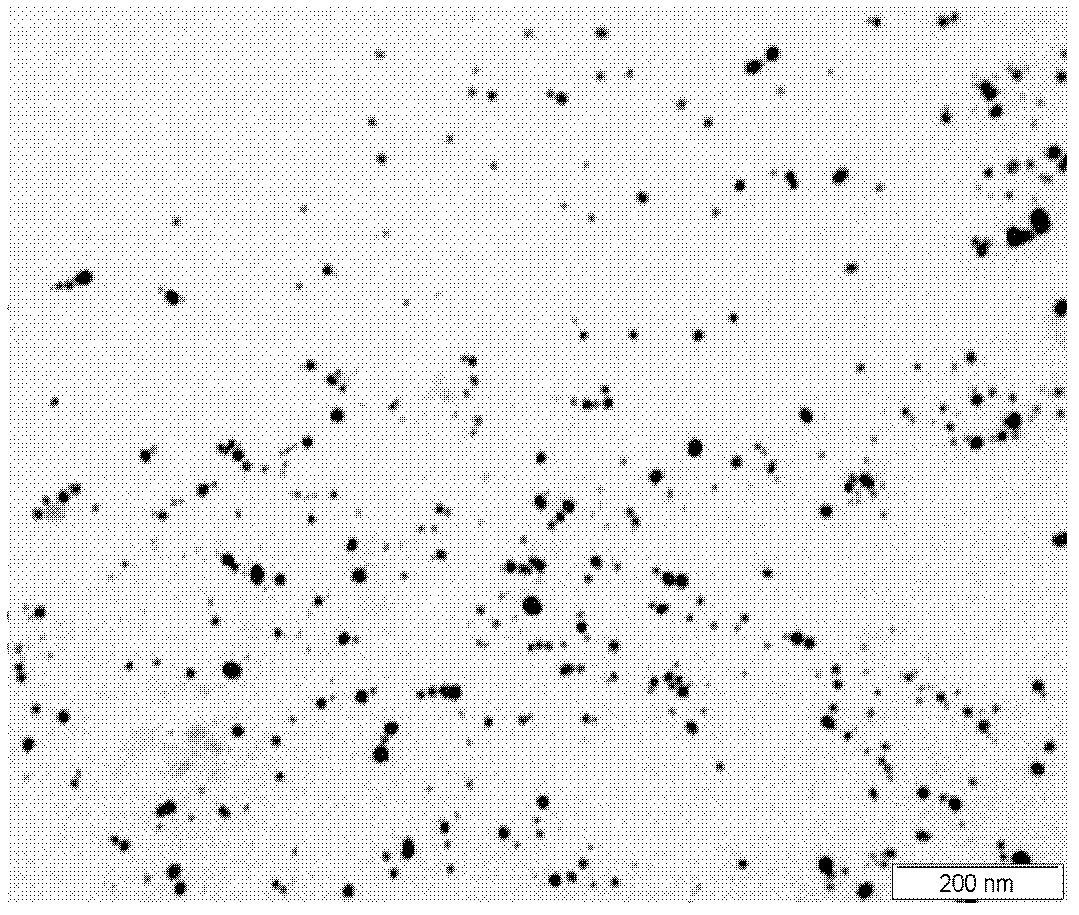

[0145] A. Preparation of Mesoporous Silicate-loaded Nano-Silver Inorganic Antibacterial Agent Suspension

[0146] (1) Natural zeolite powder (average particle size less than 0.5 μm) produced by Shijiazhuang Huihuangyuan Zeolite Factory was activated with 6N nitric acid for 10 hours at room temperature. The weight ratio of natural zeolite powder to nitric acid was 1, and then washed with water for 3 times , and then neutralized with 10% sodium hydroxide solution by weight to make the pH value reach 6.9, and then centrifuged to obtain active mesoporous silicate;

[0147] (2) Add 30 parts by weight of the active mesoporous silicate and 50 parts by weight of water into the NGJ-3 high-speed mixer produced by Qingdao Hongxiang Petroleum Machinery Manufacturing Co., Ltd., and stir for 1 hour at a rotating speed of 4000r / min to obtain A solu...

Embodiment 2

[0153] Embodiment 2: the preparation of clothing sterilization liquid of the present invention

[0154] Its preparation steps are as follows:

[0155] A. Preparation of Mesoporous Silicate-loaded Nano-Silver Inorganic Antibacterial Agent Suspension

[0156] (1) Natural zeolite powder (average particle size less than 0.5 μm) produced by Shijiazhuang Huihuangyuan Zeolite Factory was activated with 2N nitric acid for 9 hours at room temperature. The weight ratio of natural zeolite powder to nitric acid was 3, and then washed with water for 3 times , and then neutralized with 10% sodium hydroxide solution by weight to make the pH value reach 7.0, and then centrifuged to obtain active mesoporous silicate;

[0157](2) Add 38 parts by weight of the active mesoporous silicate and 65 parts by weight of water into the NGJ-3 high-speed mixer produced by Qingdao Hongxiang Petroleum Machinery Manufacturing Co., Ltd., after stirring for 0.8h at a rotating speed of 1000r / min Obtain an acti...

Embodiment 3

[0163] Embodiment 3: the preparation of clothing sterilization liquid of the present invention

[0164] Its preparation steps are as follows:

[0165] A. Preparation of Mesoporous Silicate-loaded Nano-Silver Inorganic Antibacterial Agent Suspension

[0166] (1) Natural zeolite powder (average particle size less than 0.5 μm) produced by Shijiazhuang Huihuangyuan Zeolite Factory was activated with 6N nitric acid for 12 hours at room temperature, the weight ratio of natural zeolite powder to nitric acid was 2, and then washed twice with water , and then neutralized with 9% sodium hydroxide solution by weight to make the pH value reach 6.9, and then centrifuged to obtain active mesoporous silicate;

[0167] (2) Add 34 parts by weight of the active mesoporous silicate and 52 parts by weight of water into the NGJ-3 high-speed mixer produced by Qingdao Hongxiang Petroleum Machinery Manufacturing Co., Ltd., after stirring for 0.6h at a rotating speed of 2000r / min Obtain an active me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Minimum inhibitory concentration | aaaaa | aaaaa |

| Minimum inhibitory concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com