Preparation method of simple long-acting antibacterial fabric coating

An antibacterial fabric and long-lasting technology, applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of antibacterial agent shedding, fabric antibacterial performance reduction, etc., and achieve strong antibacterial activity and excellent antibacterial durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

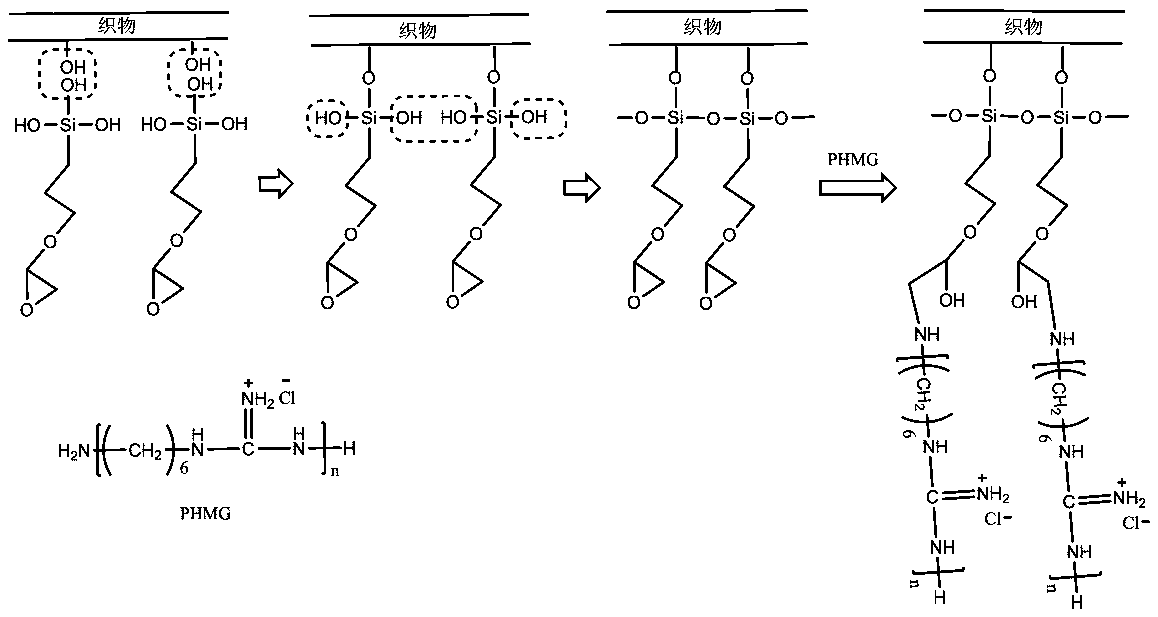

Method used

Image

Examples

Embodiment 1

[0028] A kind of concrete preparation operation step of simple long-acting antibacterial fabric coating is as follows:

[0029] (1) Preparation of treatment solution A

[0030] Mix 30g of methanol and 20g of deionized water, then add 1.5g of γ-glycidyl etheroxypropyl trimethoxysilane (KH560), mix well, and obtain a KH560 solution with a concentration of 1%, namely the treatment solution A.

[0031] (2) Preparation of treatment solution B

[0032] Dissolve 1.5g of polyhexamethyleneguanidine hydrochloride (PHMG) in 50g of methanol to obtain a PHMG solution with a concentration of 1%, that is, treatment solution B.

[0033] (3) Fabric treatment

[0034] Soak the treated fabric in treatment solution A for 15 minutes, take it out and dry it at 160°C for 1 hour; then react it in treatment solution B for 48 hours at a stirring speed of 150r / min, take it out, and rinse it with deionized water for 5 times. Just dry it at 50°C.

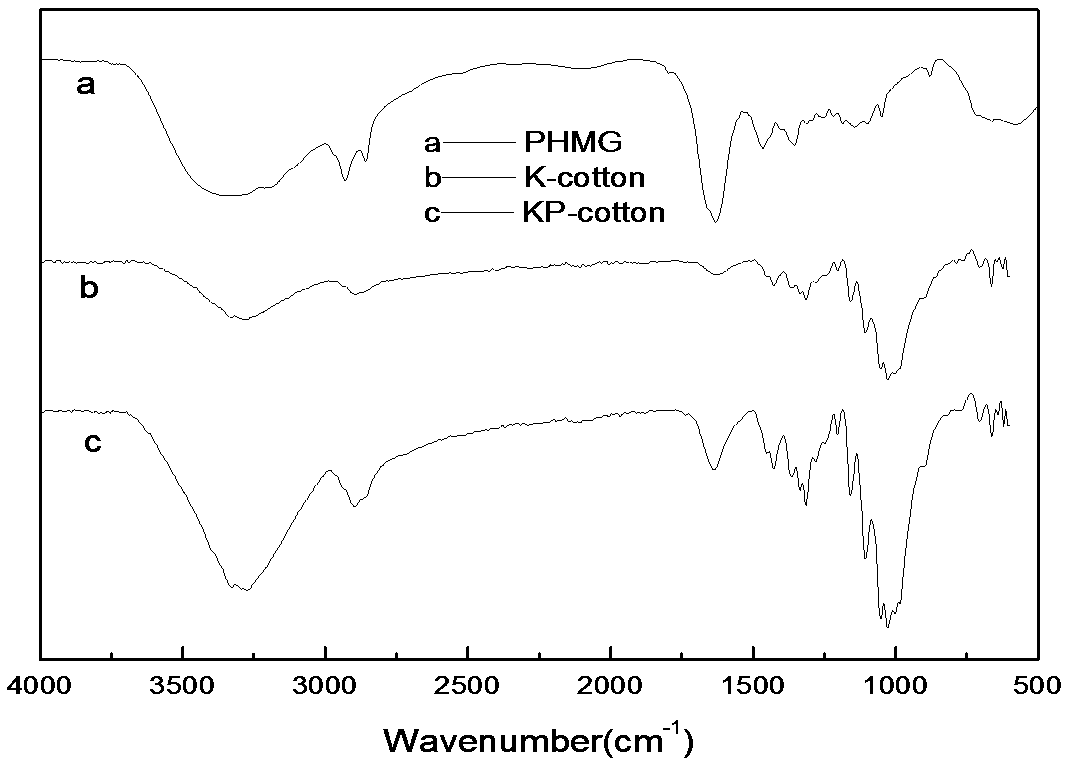

[0035] See figure 2 , where the 1080cm of the b cur...

Embodiment 2

[0039] A kind of concrete preparation operation step of simple long-acting antibacterial fabric coating is as follows:

[0040] (1) Preparation of treatment solution A

[0041] Mix 30g of ethanol with 20g of deionized water, then add 1.5g of KH560, and mix well to obtain a 1% KH560 solution, which is the treatment solution A.

[0042] (2) Preparation of treatment solution B

[0043] Dissolve 1.5g of PHMG in 50g of ethanol to obtain a 1% concentration of PHMG solution, that is, treatment solution B.

[0044] (3) Fabric treatment

[0045] Soak the treated fabric in treatment solution A for 20 minutes, take it out and dry it at 150°C for 1 hour, then react it in treatment solution B for 24 hours at a stirring speed of 200r / min, take it out, and rinse it with deionized water 4 times. Dry at 45°C.

[0046] Passed the antibacterial test, after 100 washes of the treated fabric E. coil and S. aureus The antibacterial rate can still reach more than 99%, and the fabric has excel...

Embodiment 3

[0048] A kind of concrete preparation operation step of simple long-acting antibacterial fabric coating is as follows:

[0049] (1) Preparation of treatment solution A

[0050] Mix 30g of methanol and 20g of deionized water, then add 1.6g of KH560 and mix well to obtain a 1% concentration of KH560 solution, that is, treatment solution A.

[0051] (2) Preparation of treatment solution B

[0052] Dissolve 2.0g of PHMG in 50g of methanol to obtain a PHMG solution with a concentration of 1%, namely the treatment solution B.

[0053] (3) Fabric treatment

[0054] Soak the fabric to be treated in treatment solution A for 15 minutes, take it out and dry it at 155°C for 1 hour; then react in treatment solution B for 36 hours at a stirring speed of 210r / min, take it out, and rinse it with deionized water for 5 times. Just dry it at 50°C.

[0055] Passed the antibacterial test, after 100 washes of the treated fabric E. coil and S. aureus The antibacterial rate can still reach mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com