Filling paste prepared from salt deposit exploitation tail salt and consolidated filling method thereof

A technology of paste and tailing salt, which is applied in the direction of filling, mining equipment, earth square drilling, etc., can solve the problems of land occupation and adverse impact, achieve huge environmental and social benefits, reduce land occupation, and maintain mining safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, a kind of filling paste that utilizes salt deposit to mine tailing salt, it is filling base material with the tailing salt after mineral processing of potassium halite or carnallite ore;

[0046] The main components of the filling substrate are NaCl and MgCl 2 , with hemihydrate gypsum CaSO 4 ·?H 2 O is a cementing material; the hemihydrate gypsum and the MgCl in the filling substrate 2 ·6H 2 The mass ratio of O is 0.90:1; NaCl is added as the aggregate of the solidified filling base material as required, and the concentration of the filling material is adjusted by the amount of NaCl added;

[0047] The filling base material and cementing material were mixed and stirred at 90°C to form a paste with a mass concentration of 81%.

Embodiment 2

[0048] Embodiment 2, a kind of filling paste that utilizes salt deposits to mine tailing salt, it uses potassium halite or carnallite ore as the filling base material after beneficiation and processing of tailing salt;

[0049] The main components of the filling substrate are NaCl and MgCl 2 , with hemihydrate gypsum CaSO 4 ·?H 2 O is a cementing material; the hemihydrate gypsum and the MgCl in the filling substrate 2 ·6H 2 The mass ratio of O is 1.00:1; NaCl is added as the aggregate of the solidified filling base material as required, and the concentration of the filling material is adjusted by the amount of NaCl added;

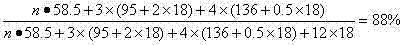

[0050] The filling base material and cementing material were mixed and stirred at 135°C to form a paste with a mass concentration of 88%.

Embodiment 3

[0051] Embodiment 3, a kind of filling paste that utilizes salt deposits to mine tailing salt, it uses potash salt or carnallite ore after beneficiation and processing tailing salt as filling base material;

[0052] The main components of the filling substrate are NaCl and MgCl 2 , with hemihydrate gypsum CaSO 4 ·?H 2 O is a cementing material; the hemihydrate gypsum and the MgCl in the filling substrate 2 ·6H 2 The mass ratio of O is 0.95:1; NaCl is added as the aggregate of the solidified filling base material as required, and the concentration of the filling material is adjusted by the amount of NaCl added;

[0053] The filling base material and cementing material were mixed and stirred at 180°C to form a paste with a mass concentration of 84%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com