Method of reinforcing quality of regenerated coarse aggregate by three stages with strong acid

A recycled coarse aggregate, three-stage technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high purchase cost of admixtures, reduce concrete strength, high water absorption, etc., and achieve huge Social benefits and environmental benefits, lower water absorption, high cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

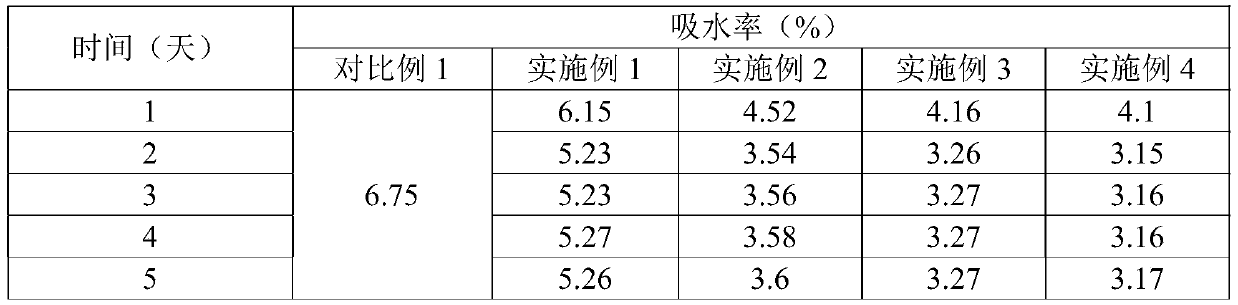

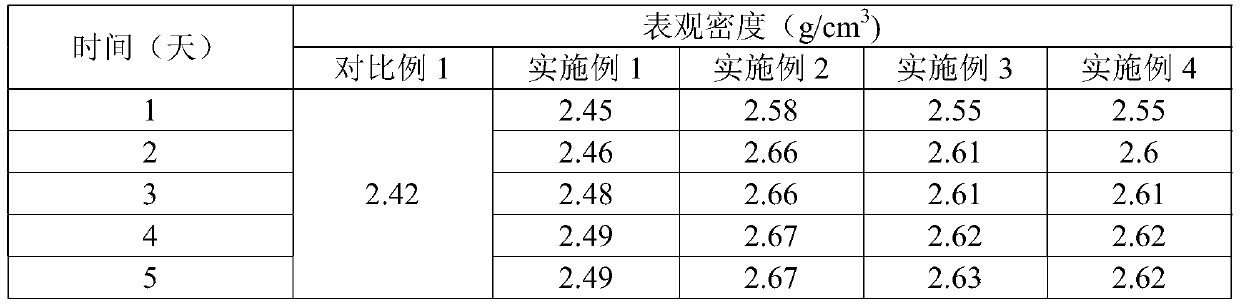

Examples

Embodiment 1

[0035] A method for strengthening the quality of regenerated coarse aggregate by using strong acid in three stages is implemented according to the following steps:

[0036] Step 1, place the regenerated coarse aggregate in a hydrochloric acid solution with a concentration of 0.05mol / L and soak for 1 day, wherein the particle size of the regenerated coarse aggregate is 5mm-30mm; test the pH value of the soaking solution every two hours, If the pH value of the soaking solution is not 1.3, add a sulfuric acid solution with a concentration of 0.05mol / L to adjust the soaking solution to a pH of 1.3;

[0037] Step 2, add a concentration of 0.05mol / L nitric acid solution to the hydrochloric acid solution soaked for a period of time in step 1, take out the regenerated coarse aggregate after soaking for another day; test the pH value of the soaking solution every two hours, if the soaking solution If the pH value is not 1.3, add sulfuric acid solution with a concentration of 0.05mol / L ...

Embodiment 2

[0043] A method for strengthening the quality of regenerated coarse aggregate by using strong acid in three stages is implemented according to the following steps:

[0044] Step 1, put the regenerated coarse aggregate in a hydrochloric acid solution with a concentration of 0.1mol / L and soak for 1 day, wherein the particle size of the regenerated coarse aggregate is 5mm-30mm; test the pH value of the soaking solution every two hours, If the pH value of the soaking solution is not 1.0, add a sulfuric acid solution with a concentration of 0.05mol / L to 0.20mol / L to adjust the soaking solution to a pH of 1.0;

[0045] Step 2: Add nitric acid solution with a concentration of 0.05 mol / L to 0.20 mol / L to the hydrochloric acid solution soaked in step 1 for a period of time, soak for another 1 day and take out the regenerated coarse aggregate; test the pH value of the soaking solution every two hours , if the pH value of the soaking solution is not 1.0, then adding a concentration of 0....

Embodiment 3

[0051] A method for strengthening the quality of regenerated coarse aggregate by using strong acid in three stages is implemented according to the following steps:

[0052] Step 1, put the regenerated coarse aggregate in a hydrochloric acid solution with a concentration of 0.15mol / L and soak it for 1 to 5 days, wherein the particle size of the regenerated coarse aggregate is 5mm to 30mm; test the concentration of the soaking solution every two hours pH value, if the pH value of the soaking solution is not 0.83, then add a sulfuric acid solution with a concentration of 0.15mol / L to adjust the soaking solution to a pH of 0.83;

[0053] Step 2, add a concentration of 0.15mol / L nitric acid solution to the hydrochloric acid solution soaked for a period of time in step 1, take out the regenerated coarse aggregate after soaking for 1 day; test the pH value of the soaking solution every two hours, if the soaking solution If the pH value is not 0.83, add a sulfuric acid solution with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com