Open-cut station body structure and construction method thereof

A technology for the main structure and station, applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of reduced service life and poor flexibility of the shield machine, and achieve shortened construction period, simple construction, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

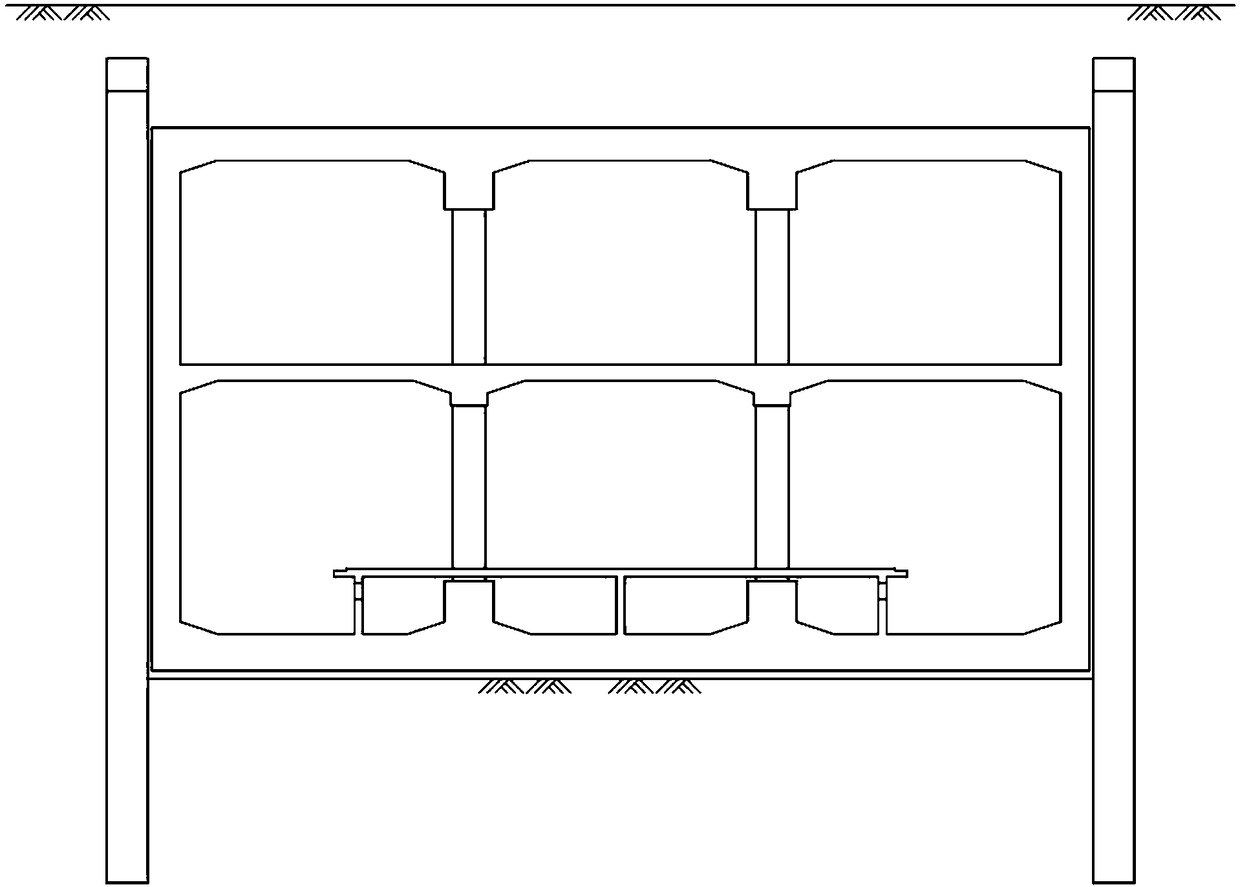

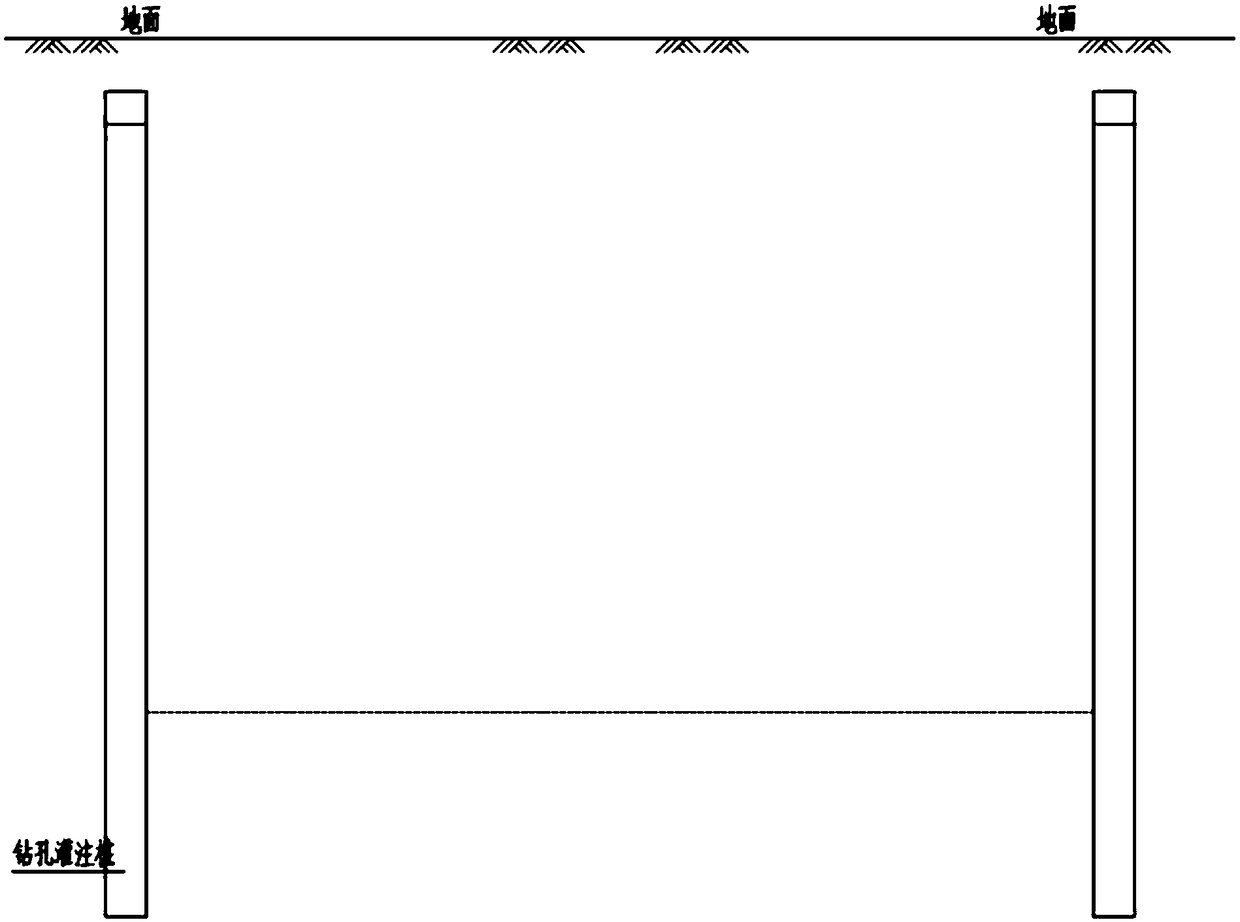

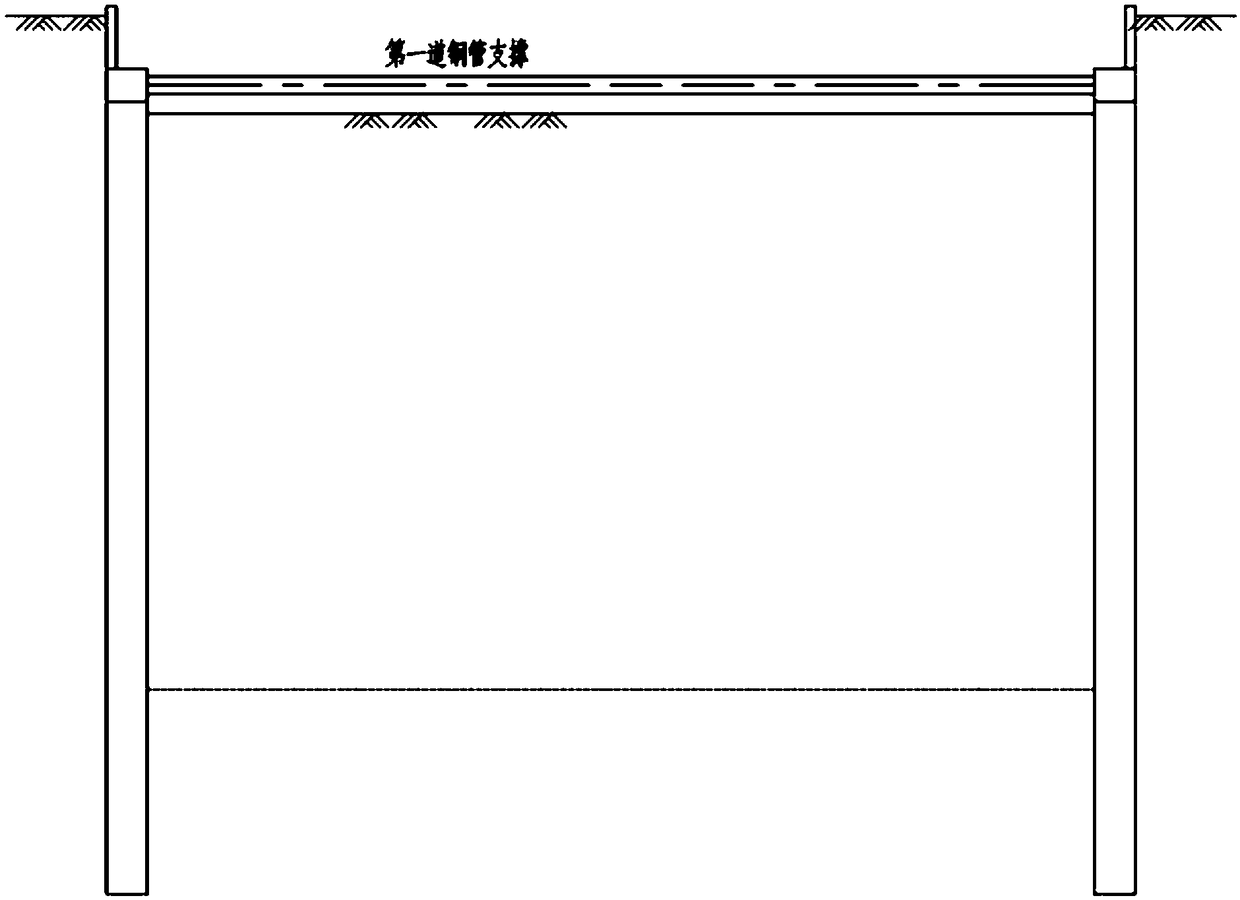

[0034] see figure 1 , a main structure of an open cut station. The main body of the station is a two-story, double-column, three-span box structure. The station is equipped with 3 entrances and exits, 1 safety entrance and 2 groups of wind pavilions. There are 3 entrances and exits on the south side of the station; No. 1 wind kiosk is located at the top of one end of the station, and No. 2 wind kiosk is set on the side of the other end of the station, hanging on the main body of the station; No. 1 safety entrance is located on the side of the station.

[0035] Taking the total length of the station as 285.75m, the effective platform center mileage right BK5+453.000, and the rail surface elevation at the effective platform center of the station as 27.970m as an example: the station is an open-cut double-layer and three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com