Heat pump tobacco leaf bulk curing barn capable of alternately operating airflow

A technology of alternating operation and intensive curing room, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of browning of tobacco leaves upstream of the airflow, inconsistent grades of tobacco leaves in the upper and lower sheds, insufficient yellowing of tobacco leaves, etc., to achieve dehydration speed and yellowing. The effect of maintaining the degree and solving the different speed of yellowing and dehydration of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

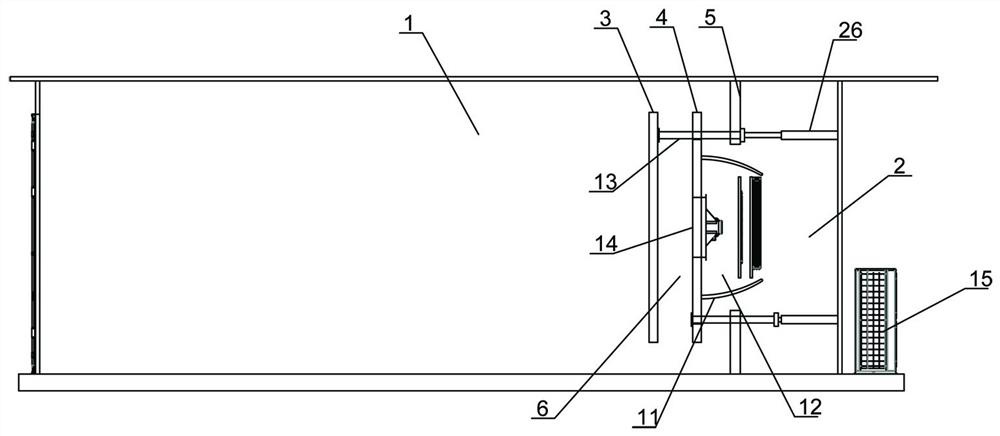

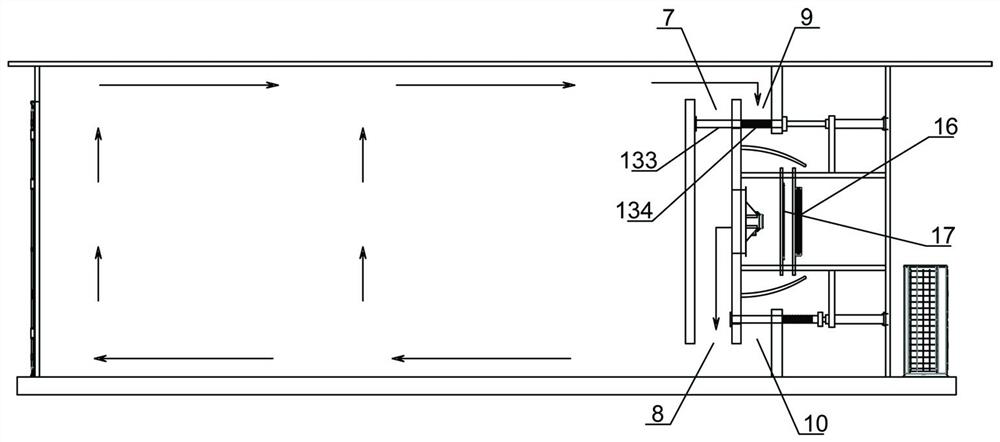

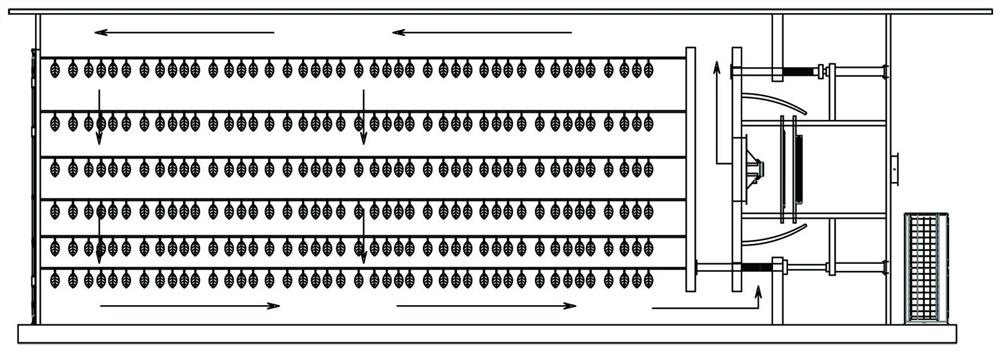

[0032] Embodiment 1: This embodiment aims to provide a heat pump tobacco leaf intensive curing barn with alternating airflow operation, which mainly aims at the defects existing in the existing single airflow cycle, which may easily cause the tobacco leaves to turn yellow and dehydrate at different speeds, and the tobacco leaves in the upper and lower sheds are not suitable for curing. It is difficult to take care of the problems. This embodiment provides a heat pump tobacco leaf intensive curing barn with multiple airflow cycles running alternately.

[0033] Such as Figure 1-5 As shown in , this embodiment mainly provides a heat pump tobacco leaf intensive curing barn with alternating airflow, which specifically includes a tobacco loading room 1, a heating room 2, an alternate switching device and a control system; wherein the tobacco loading room 1 is provided with a horizontal Hanger, the tobacco leaves are hung on the hanger, which occupies the main area of the barn, th...

Embodiment 2

[0042] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further explains the heating air duct.

[0043] The upper and lower sides of the bracket are provided with a blocking plate 11, and the blocking plate 11 wraps the air inlet end of the fan 14, the auxiliary heating wire 17 and the condenser 16 to form a heating air duct 12; Figure 1-3 As shown in , the blocking plate 11 is an arc-shaped structure or a straight-line structure.

[0044] The heating channel 12 of this embodiment is a closed channel, thereby preventing the hot air from being scattered in the heating chamber 2, improving the utilization rate of the hot air, and avoiding the influence of the hot air at the return air port on the return air, so that the heating chambers outside the heating channel are in a relatively low pressure state , to facilitate gas circulation.

Embodiment 3

[0045] Embodiment 3: This embodiment is basically the same as Embodiment 1, and the difference is that this embodiment adds a middle circulating air loop.

[0046] In this embodiment, the upper electric push rod and the lower electric push rod are respectively controlled by the controller, and the upper electric push rod and the lower electric push rod act synchronously. An air valve 27 is provided, and the valve plate inside the air valve 27 is controlled by a motor to turn over. This is an existing structure and will not be described in detail, and the motor is connected to the controller.

[0047] Thereby the present embodiment increases the circulation loop in the middle part on the basis of Embodiment 1, heat is supplied from the middle part, and the upper and lower ends return air; the embodiment has three working modes, one of which is an upwind circulation mode, and the other is an upwind circulation mode. Downwind circulation mode, the third is the circulation mode of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com