Method for solidifying sludge with high water content

A solidification method and high water content technology, applied in chemical instruments and methods, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc., to achieve the effect of improving utilization rate, high early strength and low compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

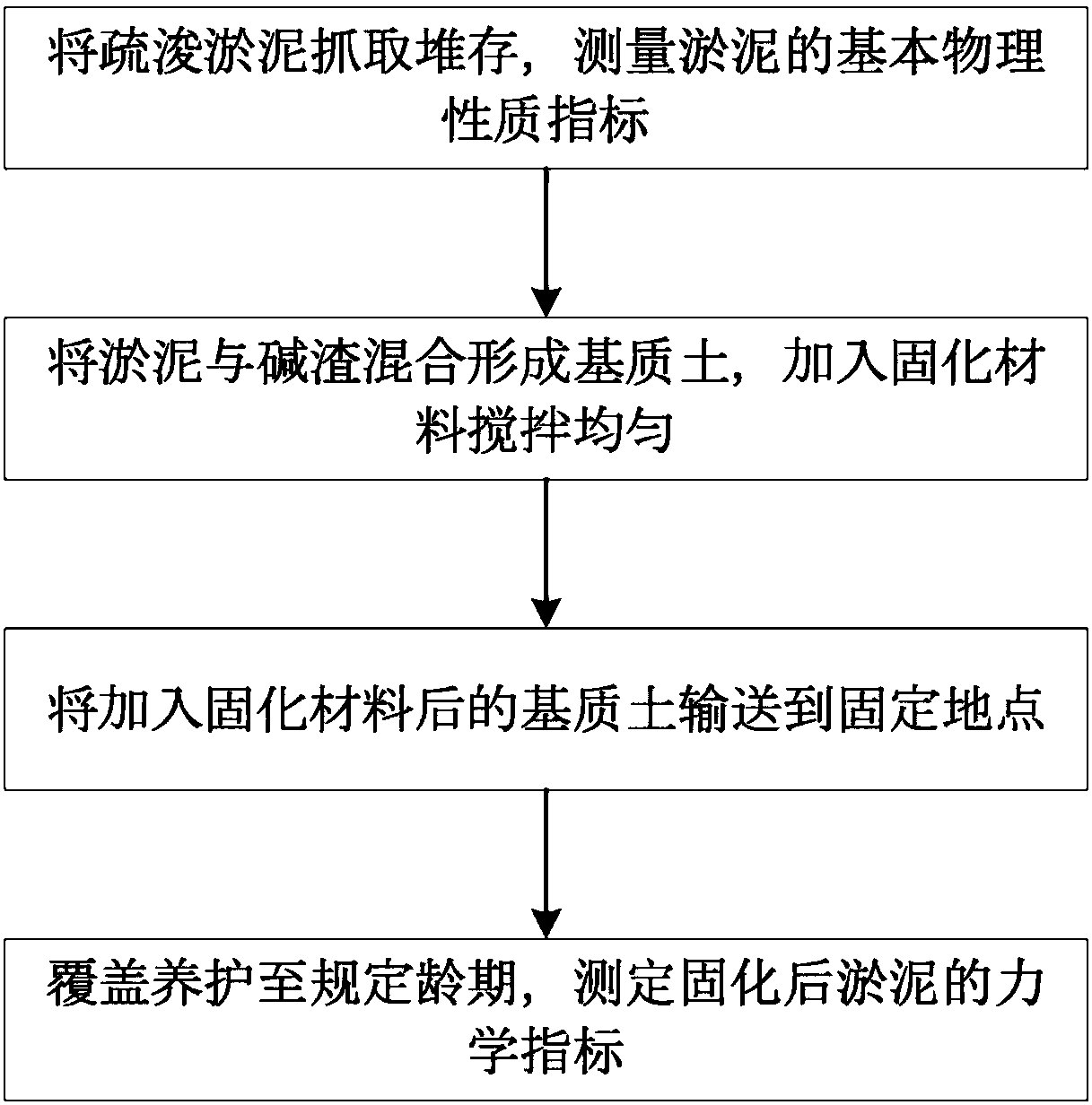

Method used

Image

Examples

Embodiment 1

[0042] The silt was taken from a construction site in Zhangzhou, Fujian. It was alluvial flow plastic to soft plastic silt with a moisture content of 52.2-92.4%, with a liquid limit of 40.9-73.1%, a plastic limit of 26.9-49.4%, and a cohesion of 3.5-11.0 kPa, the internal friction angle is 1.6-2.2°, and the compressibility coefficient is 1.48-2.32MPa -1 . The water content of the control sludge is 100%, the amount of alkali slag is 40%, the solidified material is mineral powder 15%, superabsorbent resin 0.2%, and water glass 2%. The sample was prepared by vibration method to discharge the air. After 7 days of curing in the standard curing room, the cohesion of the solidified soil was 155kPa, the internal friction angle was 30.1°, and the compressibility coefficient was 0.3MPa. -1 ; The unconfined compressive strength of the solidified soil after standard curing for 7d and 28d was 0.65MPa and 1.12MPa respectively, and the mechanical properties of the silt were well improved. ...

Embodiment 2

[0044] The silt was dredged from a lake in Wuhan City, Hubei Province. Its moisture content was about 68.2-95.5% in the grabbing and stockpiling test. It was in a flow-plastic state. The liquid and plastic limits were 66.4% and 26.2% respectively, and the organic matter content was about 1.2%. Control the water content of the sludge to 90%, the amount of alkali slag to 40%, the solidified material to be mineral powder 15%, superabsorbent resin 0.1%, and water glass 2%. The sample was prepared by vibration method to discharge the air. After 7 days of curing in the standard curing room, the cohesion of the solidified soil was 137kPa, the internal friction angle was 24.7°, and the compressibility coefficient was 0.3MPa. -1 ; The unconfined compressive strength of the solidified soil after standard curing for 7d and 28d is 0.48MPa and 0.96MPa respectively, meeting the mechanical property requirements of general engineering fill.

Embodiment 3

[0046] The silt was dredged from a certain river in Wuhan City, Hubei Province. Its water content was 140%-180% in the grabbing and stockpiling test, and it was in a flow-plastic state. The liquid and plastic limits were 97.4% and 36.2% respectively, and the organic matter content was about 9.3% burning method). Control the moisture content of the sludge to 140%, the amount of alkali slag to 50%, the solidified material to be mineral powder 20%, superabsorbent resin 0.3%, and water glass 5%. Vibration method was used to prepare samples to discharge the air. After 7 days of curing in the standard curing room, the cohesion of the solidified soil was 146kPa, the internal friction angle was 26.7°, and the compressibility coefficient was 0.4MPa. -1 ; The unconfined compressive strength of the solidified soil after standard curing for 7d and 28d is 0.41MPa and 0.86MPa respectively. Control the water content of the sludge to 180%, the amount of alkali slag to 50%, the solidified mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| compressibility factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com