Heat treatment technology for heavy drill rod with diameter being larger than or equal to phi 175 mm

A drill rod and process technology, which is applied in the field of heat treatment of heavy drill rods, can solve the problems of poor wear resistance, difficulty for manufacturers to bear, and high process cost, and achieve the effect of ingenious heat treatment process, reducing the number of replacements and saving steel resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

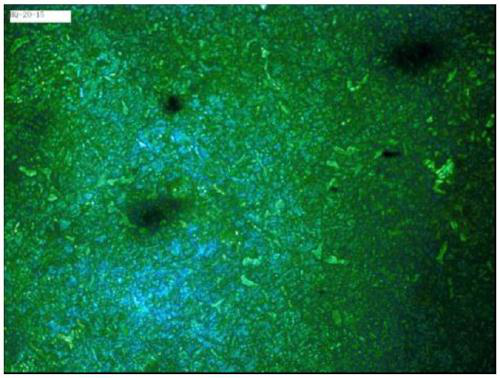

[0047] Such as figure 1 Shown is the sample HQ-20-15 under the 100°C boiling water quenching process of the present invention, using a φ195×300mm round steel to simulate a φ195mm drill rod, a 500-fold microscope photo of the center of the round steel, and the black spot in the lens is a microscope Please ignore the pollution. The sample HQ-20-15 shows that it is not perfect quenched sorbite. After testing, its hardness is HV440;

Embodiment 2

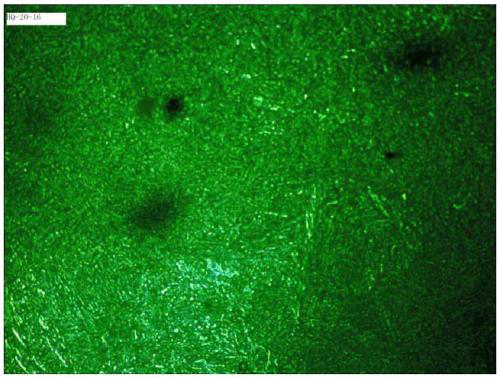

[0049] Such as figure 2 Shown is the sample HQ-20-16 under the 85-75 ℃ hot water quenching process of the present invention, using φ195×300mm round steel to simulate the 500 times microscopic structure photo of the round steel core after the φ195mm drill rod, the black in the lens Spots are microscopic contamination, please ignore. The sample HQ-20-16 shows a more perfect quenched sorbite. After testing, its hardness is HV498.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com