Method for producing calcium carbide by virtue of waste gas

A technology of calcium carbide and exhaust gas, applied in chemical instruments and methods, climate sustainability, inorganic chemistry, etc., can solve problems such as suboptimal comprehensive utilization schemes, achieve huge economic and environmental benefits, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

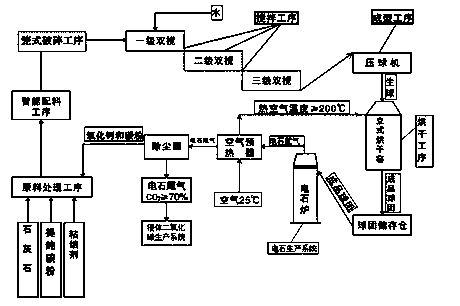

[0042] Such as figure 1As shown, a method for producing calcium carbide using waste gas is characterized in that it includes a calcium carbide furnace charge pellet production system, a calcium carbide waste gas recovery and utilization system, a calcium carbide production system and a liquid carbon dioxide production system,

[0043] The described calcium carbide charge pellet production system comprises the steps:

[0044] Step (1), the selection of raw materials for calcium carbide furnace charge pellets: the first is calcium oxide dust and carbon powder in the waste gas dust of calcium carbide production; the second is to select limestone with a calcium content ≥ 50%; Mineral processing, fixed carbon ≥ 90%, ash content ≤ 2.5% purified carbon powder; the fourth is to choose Xuguang brand new composite industrial gasification briquette binder;

[0045] In step (2), the calcium carbide furnace charge pellet raw material selected in step (1) is processed through the raw mater...

Embodiment 2

[0059] The difference between embodiment 2 and embodiment 1 is:

[0060] In the step (2), according to the mass percentage, the limestone powder and reclaimed calcium oxide powder account for 80%; the purified carbon powder and reclaimed carbon powder account for 16%, and the binding agent accounts for 4%; the raw material treatment process is Crush the limestone to a particle size of 2.9mm;

[0061] Add water at the inlet of the primary mixer in step (3), so that the mass fraction of the total moisture is 14% of the material;

[0062] Drying in step (5) until the moisture content of the pelletized calcium carbide is 5%;

[0063] All the other are identical with embodiment 1.

Embodiment 3

[0065] The difference between embodiment 3 and embodiment 1 is:

[0066] In the step (2), according to the mass percentage, the limestone powder and reclaimed calcium oxide powder account for 70%; the purified carbon powder and reclaimed carbon powder account for 26%, and the binding agent accounts for 4%; the raw material treatment process is Crush the limestone to a particle size of 3.1mm;

[0067] Add water at the inlet of the primary mixer in step (3), so that the mass fraction of the total moisture is 10% of the material;

[0068] Dry in step (5) until the moisture content of the pelletized calcium carbide is 3%;

[0069] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com