Method and device for non-destructive testing of pavement quality by radar

A non-destructive testing and radar technology, used in radio wave measurement systems, measurement devices, and radio wave reflection/re-radiation, etc. Destruction and other problems, to achieve the effect of improving detection efficiency and detection accuracy, significant social and environmental benefits, and shock absorption protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

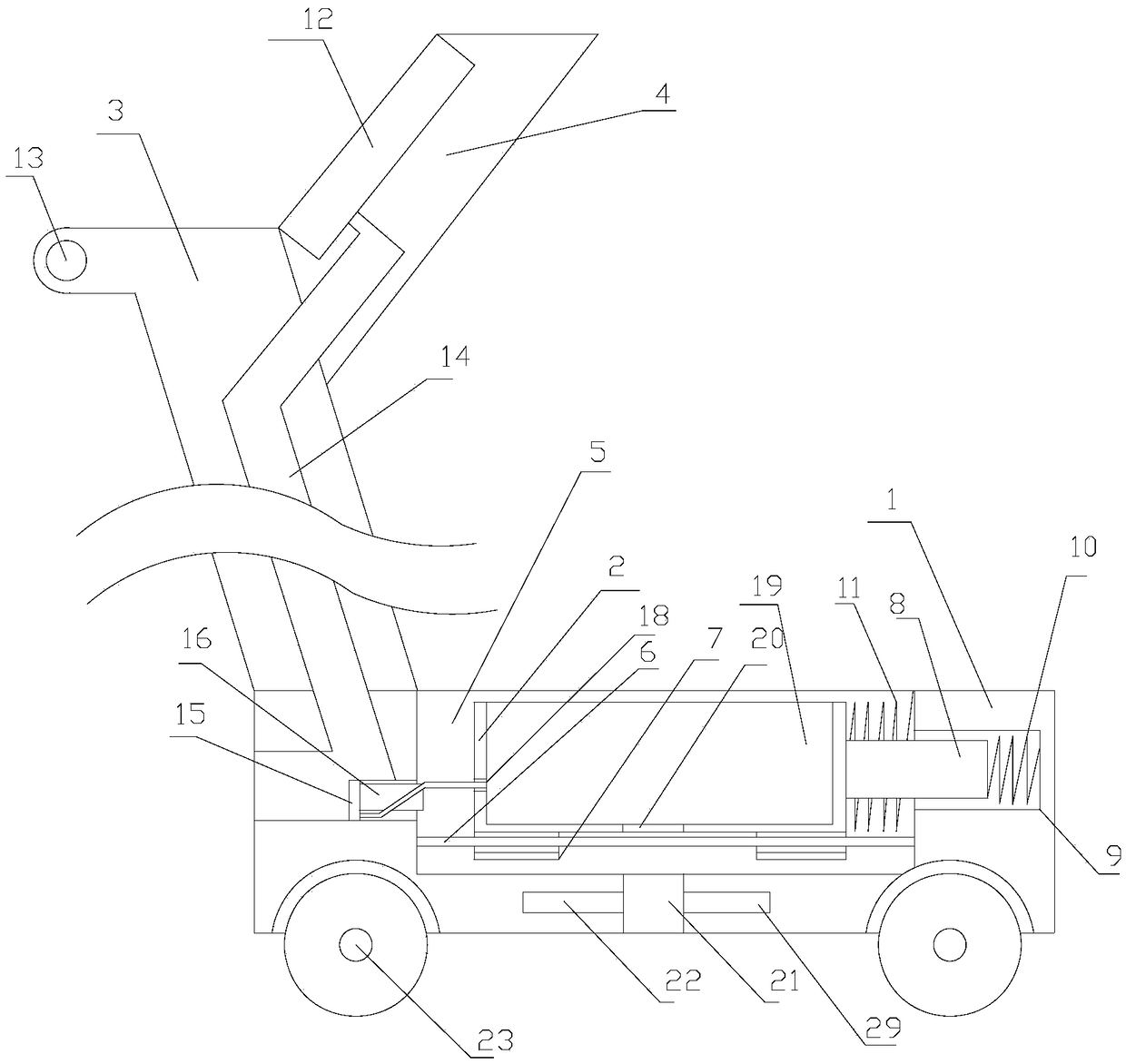

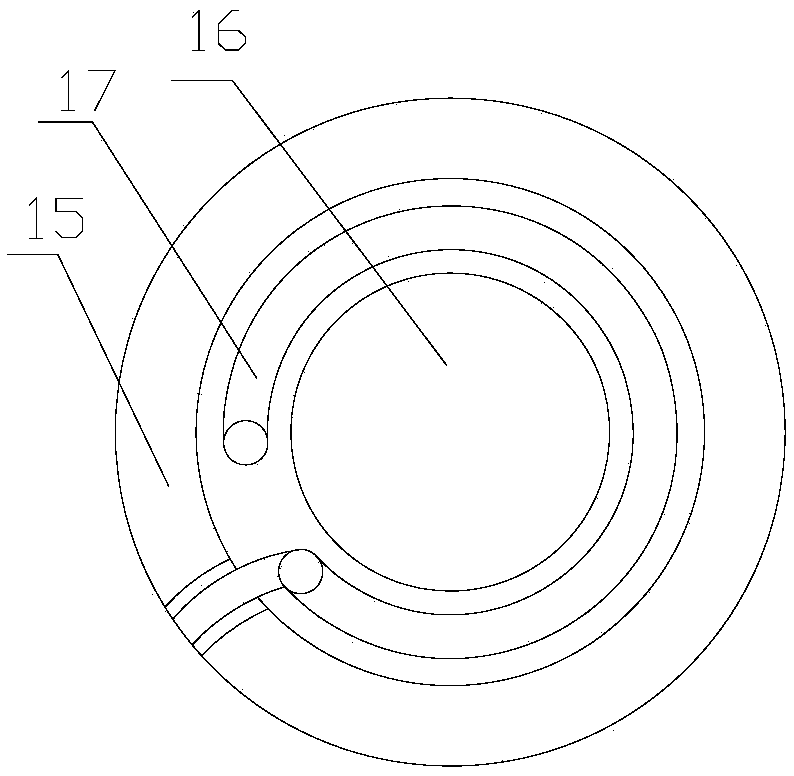

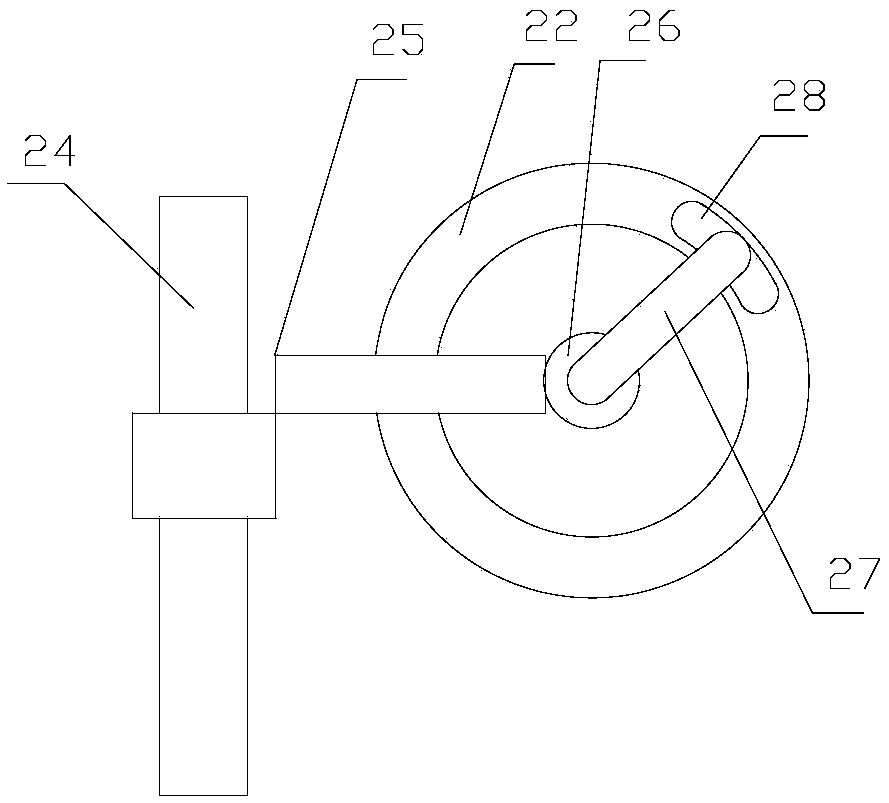

[0014] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

[0015] It should be noted that the up, down, left, and right mentioned in the present invention are attached figure 1 Up and down and left and right are shown.

[0016] The present invention proposes a method for radar non-destructive detection of road surface quality, comprising the following steps,

[0017] 1. The dielectric constant of the pavement layer is determined by the total reflection method, and the thickness of the pavement layer is calculated and verified based on the time history method; the ground-penetrating radar antenna is used, and the ground-penetrating radar antenna includes a transmitting antenna and a receiving antenna. Layer transmits signals, captures weak reflection signals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com