Reversed construction method for expanding and excavating stations on sectional shield tunnel foundations of subways

A shield tunneling and construction method technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of many non-propelling operations in subway stations, low efficiency of shield equipment use, expansion of a single shield tunnel, etc., and reach the surrounding Small environmental impact, reliable and easy construction method, and the effect of removing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

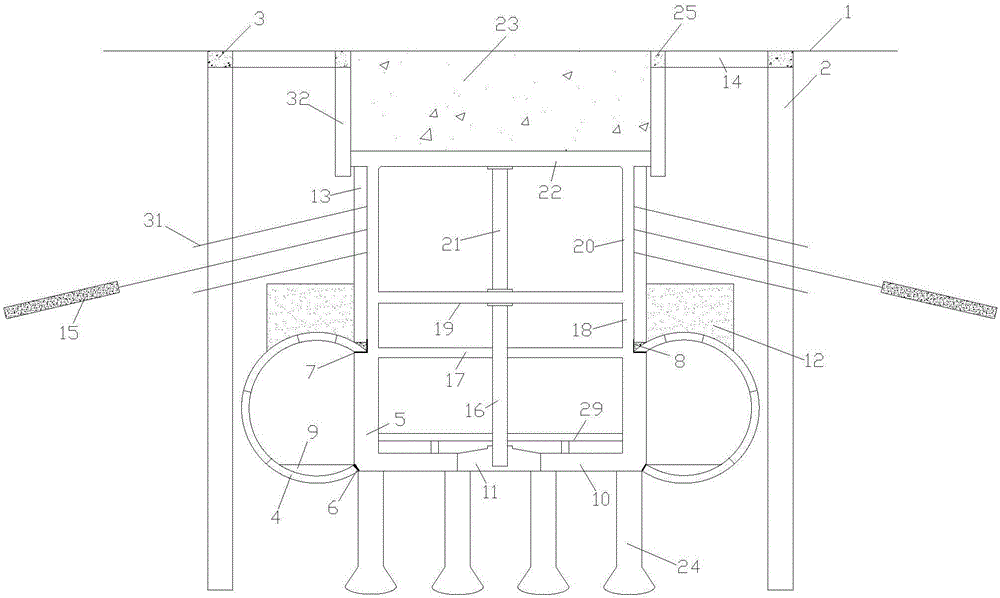

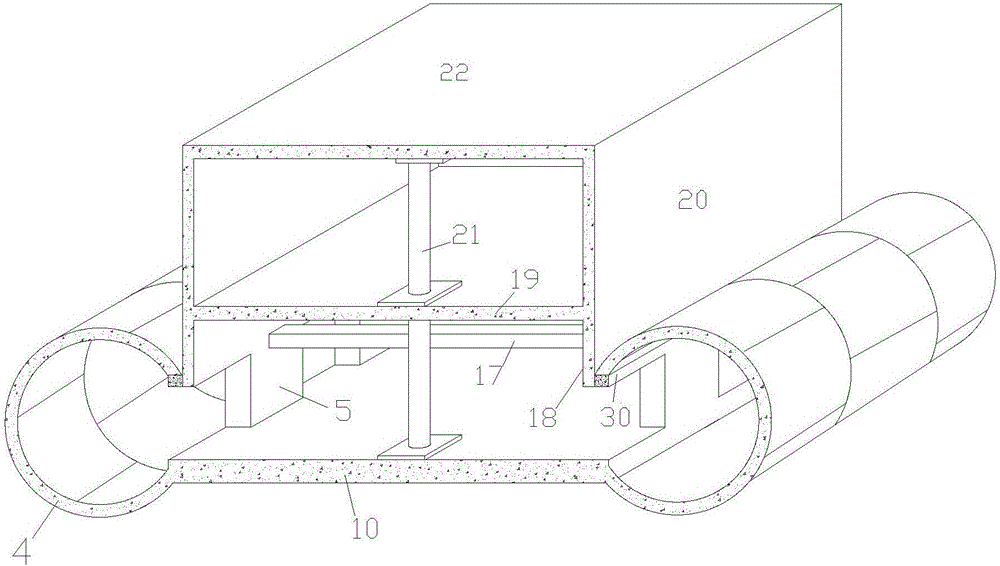

[0020] Such as Figure 1-15 As shown, the implementation example of a shallow-buried double-span subway station under an urban road of the present invention adopts a kind of reverse construction method of expanding and excavating a subway station on the basis of a shield tunnel in a subway section of the present invention, and its main structure It consists of cast-in-place reinforced concrete bottom slab 10, middle slab 19, top slab 22, ground floor side wall 18, station hall floor side wall 20, wall column 5, shield tunnel segment 4, transverse support beam 17, and central column 21 (its structure composed as figure 1 As shown), the thickness of the top covering soil of the structure is 5.5m, and the excavation section size is 12m×20.5m. In conjunction with the accompanying drawings, the construction steps of the present invention will be further specifically described.

[0021]In this embodiment, the reverse construction method of expanding and excavating the station on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com