Method for preparing water-retaining agent

A technology of water-retaining agent and cross-linking agent, applied in microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of excessive degradation, poor gel strength and heat resistance, and poor salt resistance. , to achieve the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

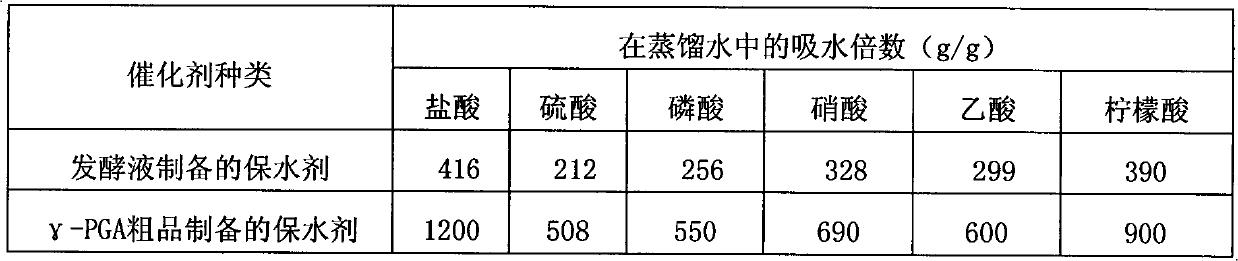

[0059] Add 4.8g of the γ-polyglutamic acid crude product described in this specification to a 50mL conical flask with a stopper, then add 20mL of distilled water, and after fully dissolving, add 1.44g of polypropylene glycol bisglycidyl ether crosslinking agent, stir evenly, and In the presence of a citric acid catalyst, γ-polyglutamic acid and polypropylene glycol bisglycidyl ether were reacted in a water bath at 60°C under the condition of pH 4.8-5.0 for 24 hours, and the obtained substance was evaporated and dried in a vacuum dryer for 24 hours. Then use a pulverizer to pulverize to a particle size of 80-100 mesh, and use the detection method described in the instructions to detect that the water absorption of the polymer is 900 times in distilled water, and the water absorption in physiological saline is 80 times.

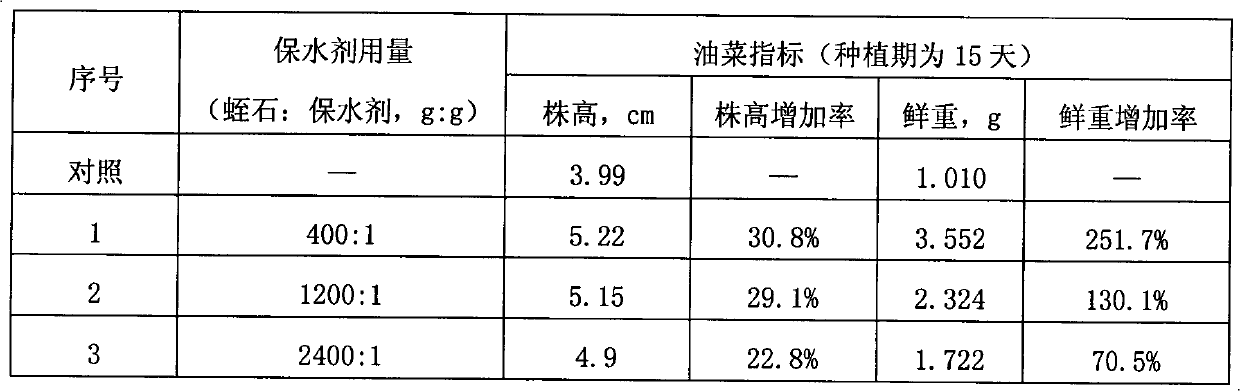

[0060] The water-retaining agent was used in a pot test, and the results are shown in the table below. Put 600g of vermiculite in each pot, set the amount of w...

Embodiment 2

[0065] Add 2.8g of crude γ-polyglutamic acid to a 50mL Erlenmeyer flask with a stopper, then add 20mL of distilled water, after fully dissolving, add 0.84g of polypropylene glycol diglycidyl ether, stir well, and then in the presence of concentrated hydrochloric acid, at pH5 .1 React γ-polyglutamic acid and polypropylene glycol bisglycidyl ether in a water bath at 40°C for 30 hours, evaporate and dry the resulting substance in a vacuum dryer for 24 hours, and use a pulverizer to crush to a particle size of 80-100 mesh , using the detection method described in the manual to detect that the water-retaining agent prepared in this example has a water absorption multiple of 1200 times in distilled water, and an absorption multiple of 105 times in physiological saline.

Embodiment 3

[0067] Add 50g of gamma-polyglutamic acid fermentation broth (the content of gamma-polyglutamic acid is 17g / L) in a 100mL Erlenmeyer flask with a stopper, add 5g of polypropylene glycol diglycidyl ether, stir well, and then in the presence of concentrated hydrochloric acid , let γ-polyglutamic acid and polypropylene glycol bisglycidyl ether react in a 60°C water bath at pH 4.8 for 1 hour, then precipitate with 50 mL of absolute ethanol, dry the precipitate in an oven at 50°C for 24 hours, and then Use a pulverizer to crush to a particle size of 80-100 mesh, and use the detection method described in the manual to detect that the water-absorbing ratio of the water-retaining agent is 416 times in distilled water, and the water-absorbing ratio in normal saline is 68 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com