A primary support foot support device and method for a large-section tunnel with weak surrounding rock

A technology of weak surrounding rock and supporting devices, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., to achieve the effects of reduced settlement, large pipe diameter, and coordinated settlement and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

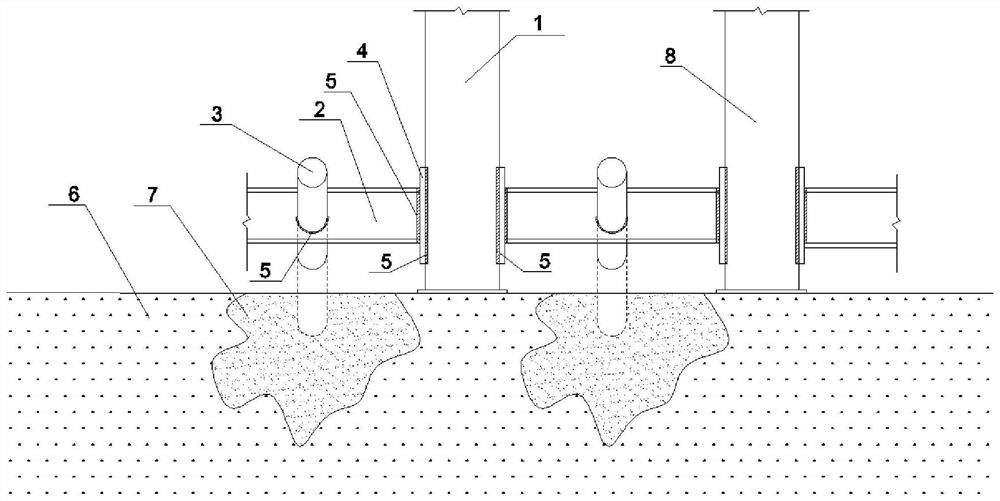

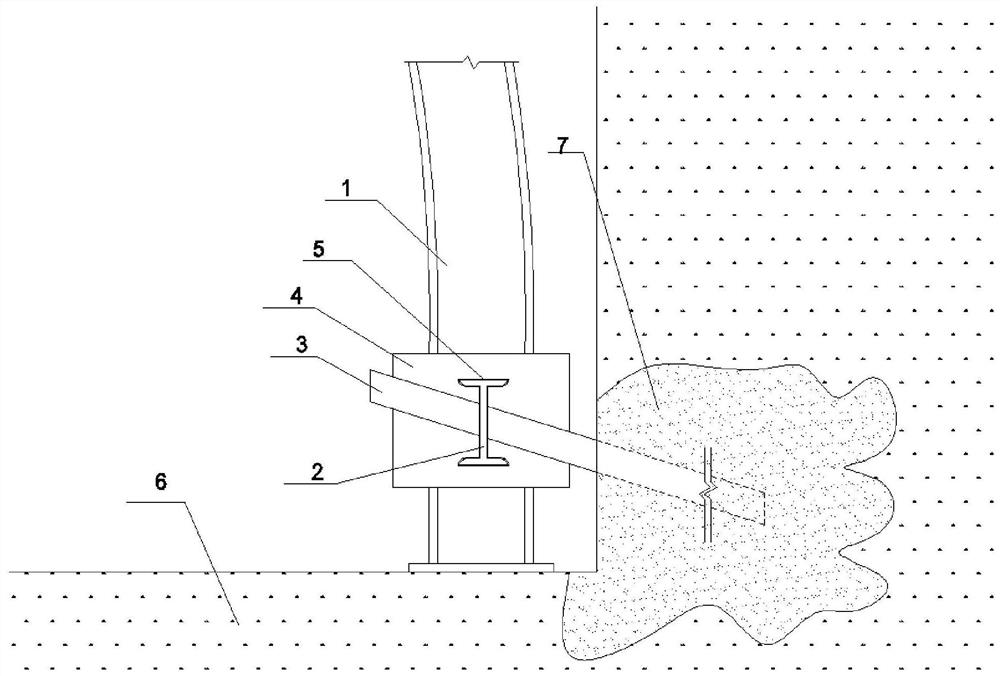

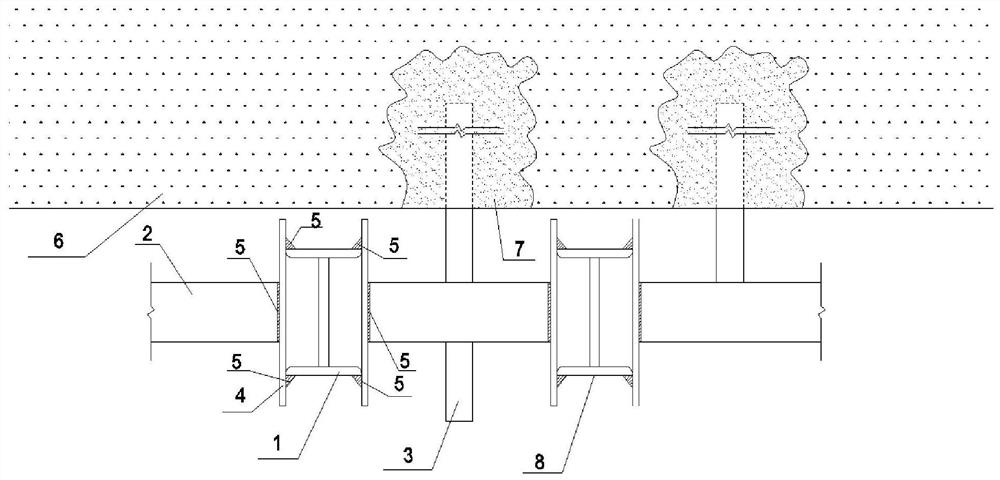

[0043] Please refer to Figure 1 to Figure 5, Embodiment 1 discloses a primary support foot support device for large-section tunnels with weak surrounding rocks, including connected connecting section steel 2, steel plate 4 and grouting pipe shed 3, wherein the grouting pipe shed 3 can be used to The grout is driven into the surrounding rock 6. In this embodiment, the diameter of the grouting pipe shed 3 is 90-110mm, the length of the injection is 4-5m, and the length of the part that is not driven outside the surrounding rock 6 is 20-30cm; The section steel 2 is connected to the grouting pipe shed, the steel plate 4 is used to connect the initial support section steel 1, and the connection section steel 2 includes multiple pieces, and the connection section steel 2 is connected between every two steel plates 4 to form a connection part, and the adjacent connection parts are used for common connection The same primary section steel 1; the grouting pipe shed 3 includes multiple...

Embodiment 2

[0054] Embodiment 2 discloses a primary support foot support method for a large-section tunnel with weak surrounding rock, using the primary support foot support device for a large-section tunnel with weak surrounding rock as described in Embodiment 1, including the following steps:

[0055] 1) Tunnel excavation, erecting the first primary support section steel 1;

[0056] 2) Drive the grouting pipe shed 3 into the side of the first primary support section steel 1, and perform grouting after the grouting pipe shed 3 is driven into the predetermined length;

[0057] 3) Connect the grouting pipe shed 3, the connecting section steel 2, the steel plate 4 and the first primary support section steel, and spray concrete;

[0058] 4) Excavate and erect the next primary support section steel 8 to ensure that the grouting pipe shed is located between the two primary support section steels;

[0059] 5) Repeat steps 2) to 4) to complete the preliminary work of the entire section;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com