Tunnel steel temporary inverted arch with rapid assembly and disassembly

A fast and temporary technology, applied in tunnels, tunnel linings, temporary shields, etc., can solve the problems of high noise, danger, and time-consuming installation process during the demolition process, and achieve improved construction safety, good construction environment, and convenient and quick demolition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] see Figure 4 The structural form of the tunnel steel quick disassembly and assembly temporary invert in this embodiment is that each temporary invert is composed of a fixed section 1 in the middle, a movable section 3 located at both ends of the fixed section, and a fixed section 1 connected to the fixed section. Composed of connection section 2 with activity section 3;

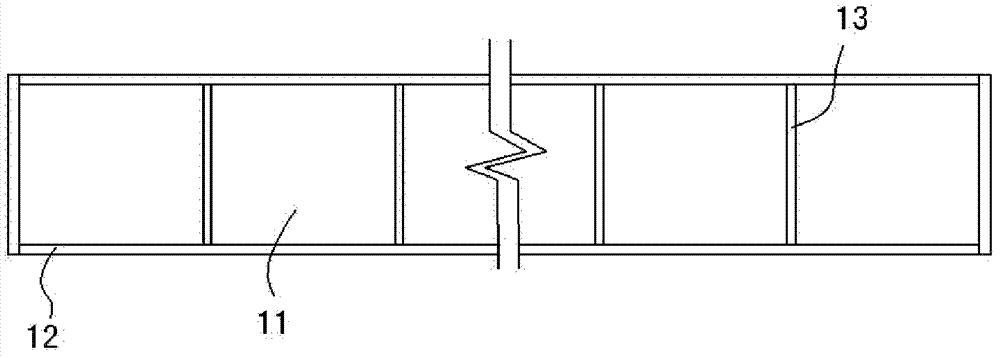

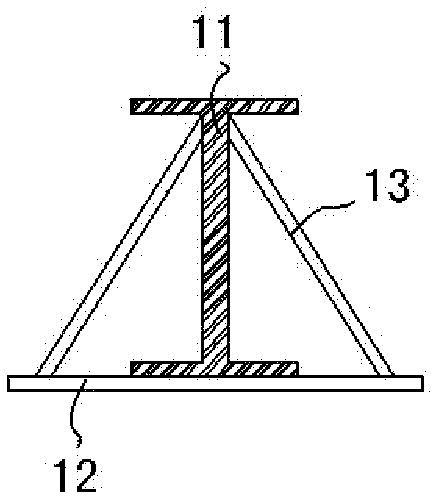

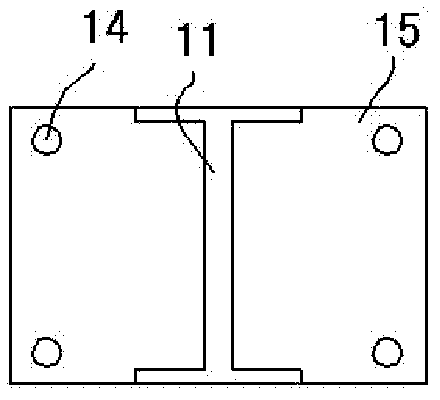

[0020] Such as Figure 1a , Figure 1b and Figure 1c As shown, the fixed section 1 is to weld the fixed section reinforced steel plate 12 on the bottom plate of the fixed section "I" steel plate 11 with a width greater than the fixed section "I" steel bottom plate width, and the fixed section reinforced steel plate 12 and the fixed section I-shaped steel Between the webs of 11, along the length direction of the fixed joint, there are fixed joint reinforcing steel bars 13 welded at intervals, and the fixed joint connecting end plates 15 with the fixed joint bolt holes 14 are fixedly welded at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com