Long-short-pile composite foundation applied to deep soft soil regions

A technology of composite foundation and long and short piles, which is applied in the direction of foundation structure engineering, construction, etc., can solve the problems of small horizontal constraint force, uneven load sharing, and large settlement, so as to avoid displacement or damage of pile body and pile foundation Quality is safe and reliable, quality is safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

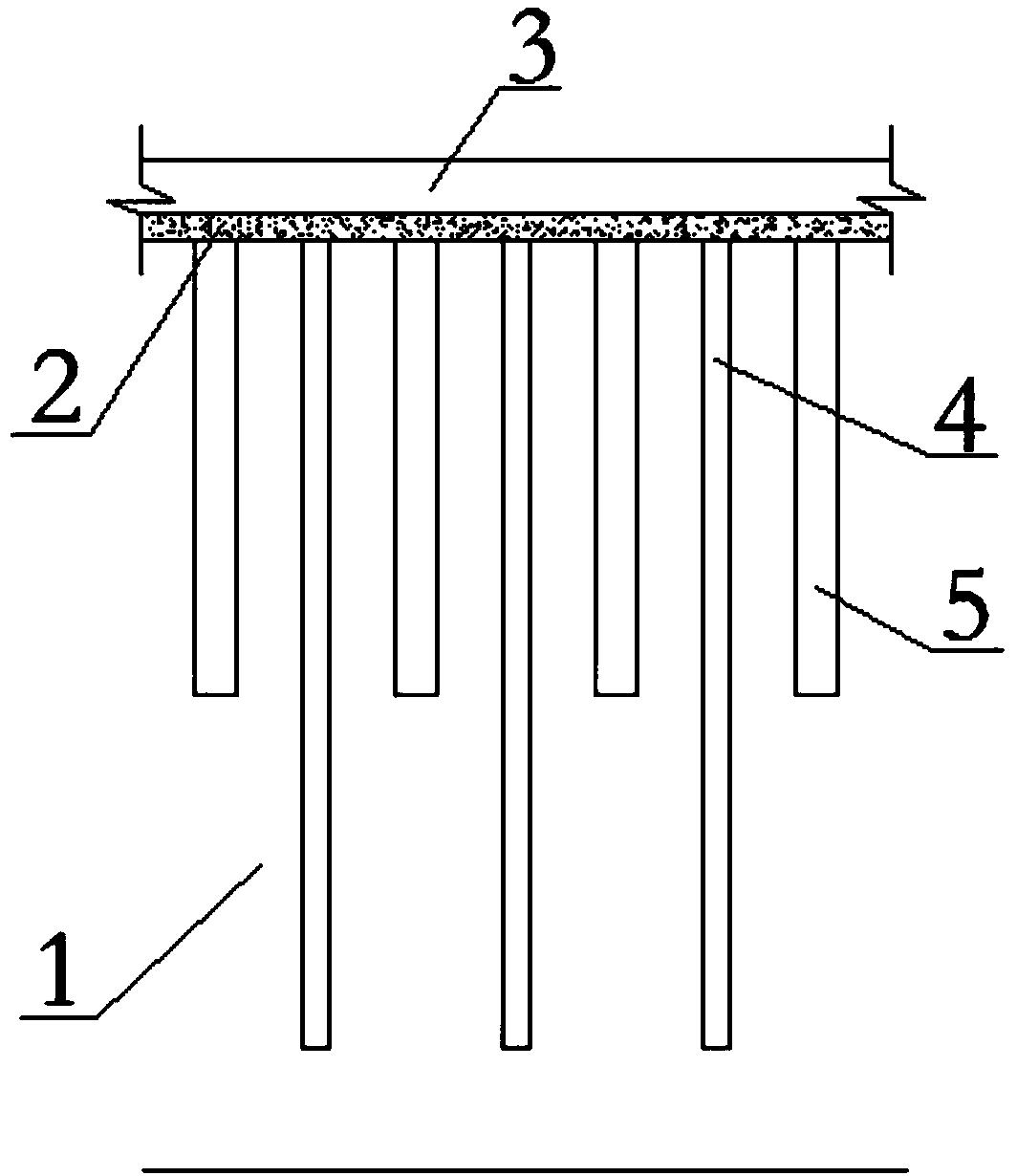

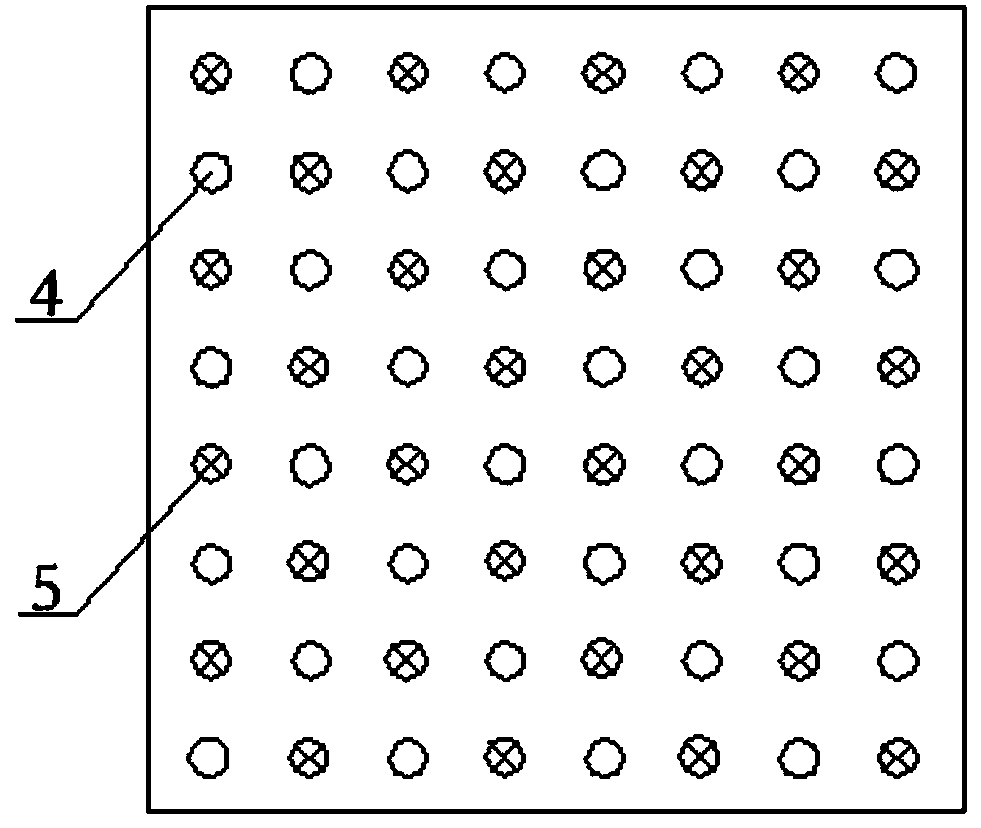

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing, so that those skilled in the art can understand more clearly, as figure 1 and figure 2 Shown, the present invention adopts following embodiment, comprises weak soil layer 1, mattress layer 2, foundation 3, long pile 4 and short pile 5; Described mattress layer 2 is positioned on weak soil layer 1, and described foundation 3 is positioned at On the cushion layer 2; the cushion layer may be able to adjust the load sharing ratio of the pile and the soil between the piles and the load sharing ratio of the long pile and the short pile. Described long pile 4 and short pile 5 are arranged in the soft soil layer 1; Located in the soft soil layer 1; the long piles 4 are evenly and symmetrically located around the short piles 5, and the short piles 5 are evenly and symmetrically located around the long piles 4; It can evenly bear the load and further reduce the settlement;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com