Road and bridge transition section grouting construction method used during jacking construction

A construction method and transition section technology, applied in the field of transportation, can solve the problems of endangering the safety of railway traffic, personal safety, large box volume and weight, and affecting traffic safety, and achieve convenient operation, control of settlement deformation, and obvious economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The grouting construction method for the road and bridge transition section during jacking construction provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

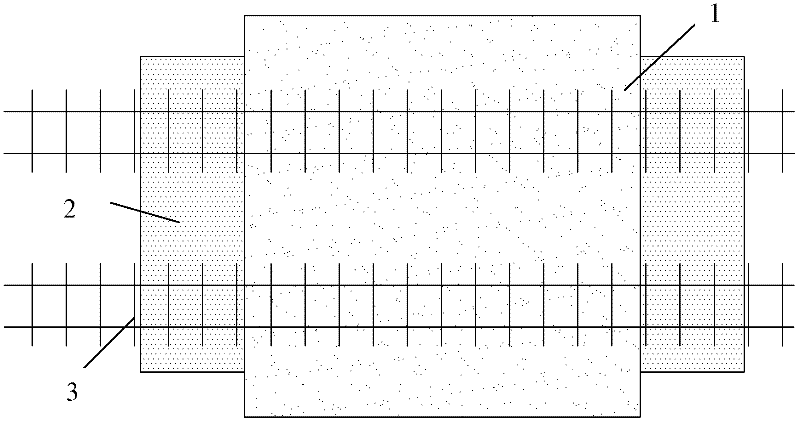

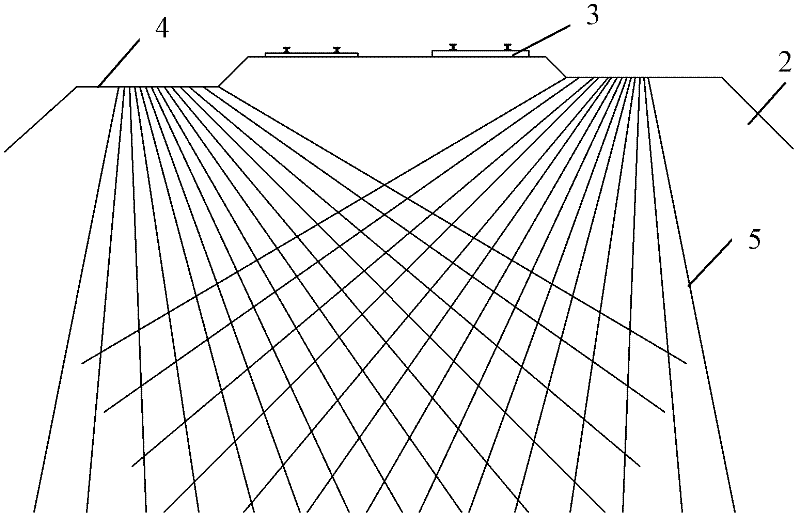

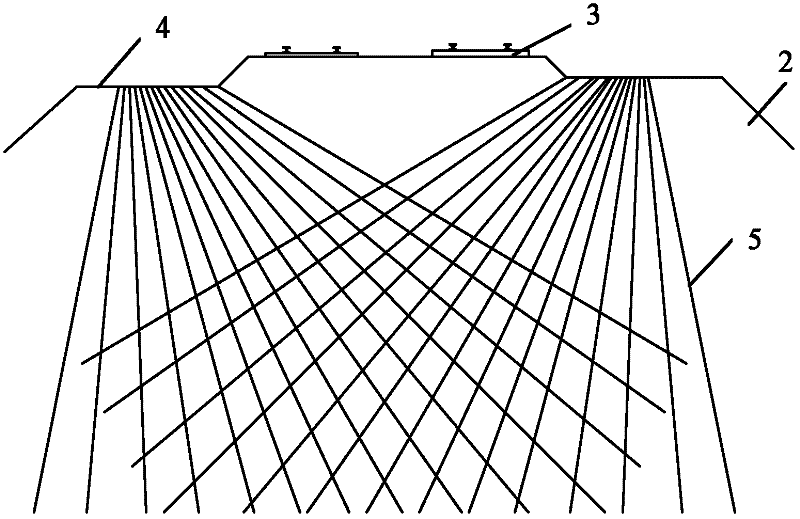

[0012] Such as figure 2 and figure 1 As shown, the grouting construction method of the road-bridge transition section in the jacking construction provided by the present invention is to use a drill pipe to drill more holes from the railway shoulder 4 on both sides of the road-bridge transition section 2 in an obliquely downward fan-shaped manner to the bottom of the railway 3. Row fan-shaped grouting holes 5, take out the drill pipe after each hole is drilled, then insert the grouting flower tube and inject the grouting liquid, stop grouting when the grouting reaches 2 meters from the ground and block the grouting port, then Move to the next hole position, the angle range of the grouting fan-shaped area is 15-75° from the subgrad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com