Patents

Literature

32results about How to "Efficient and reliable removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

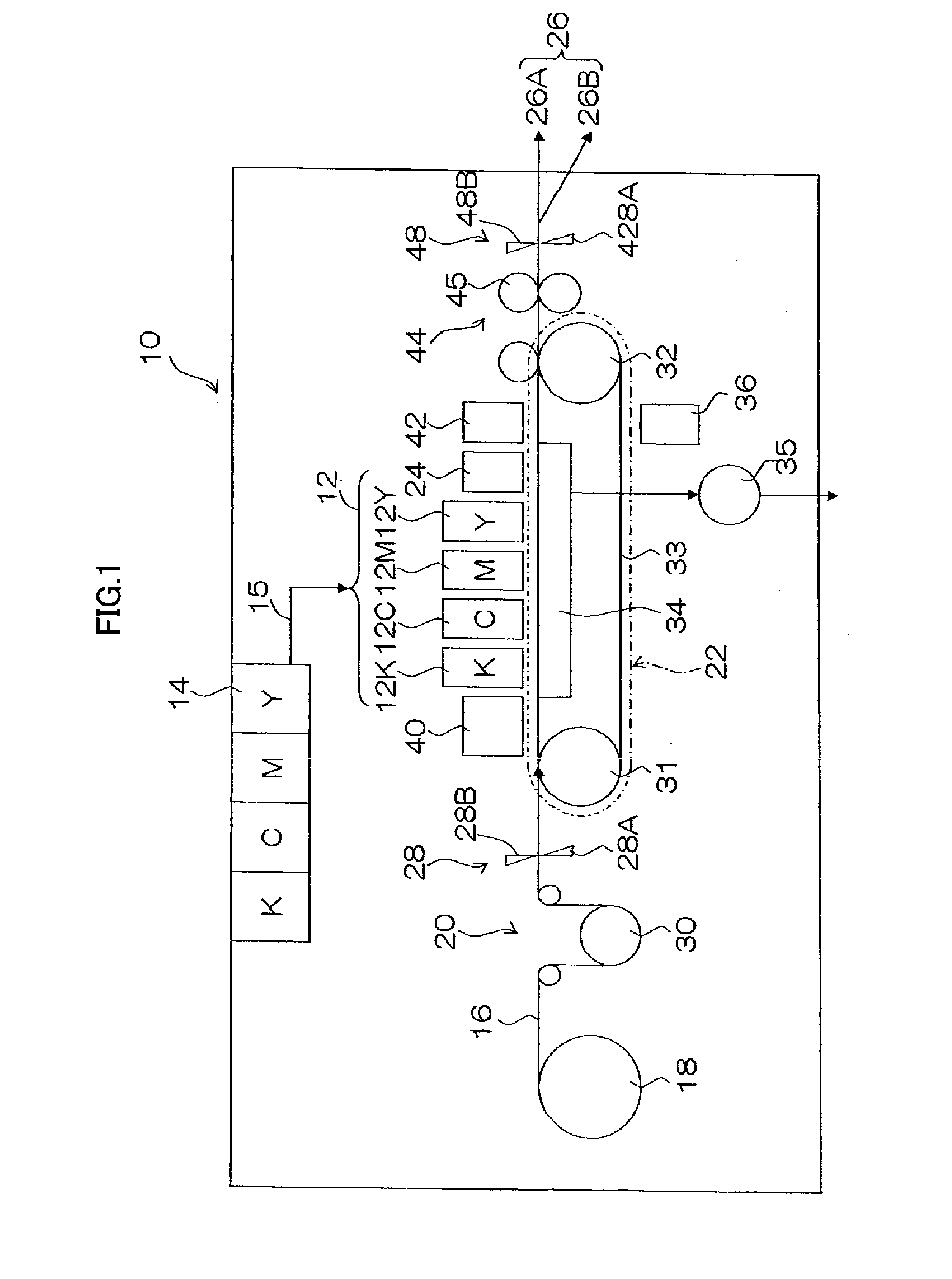

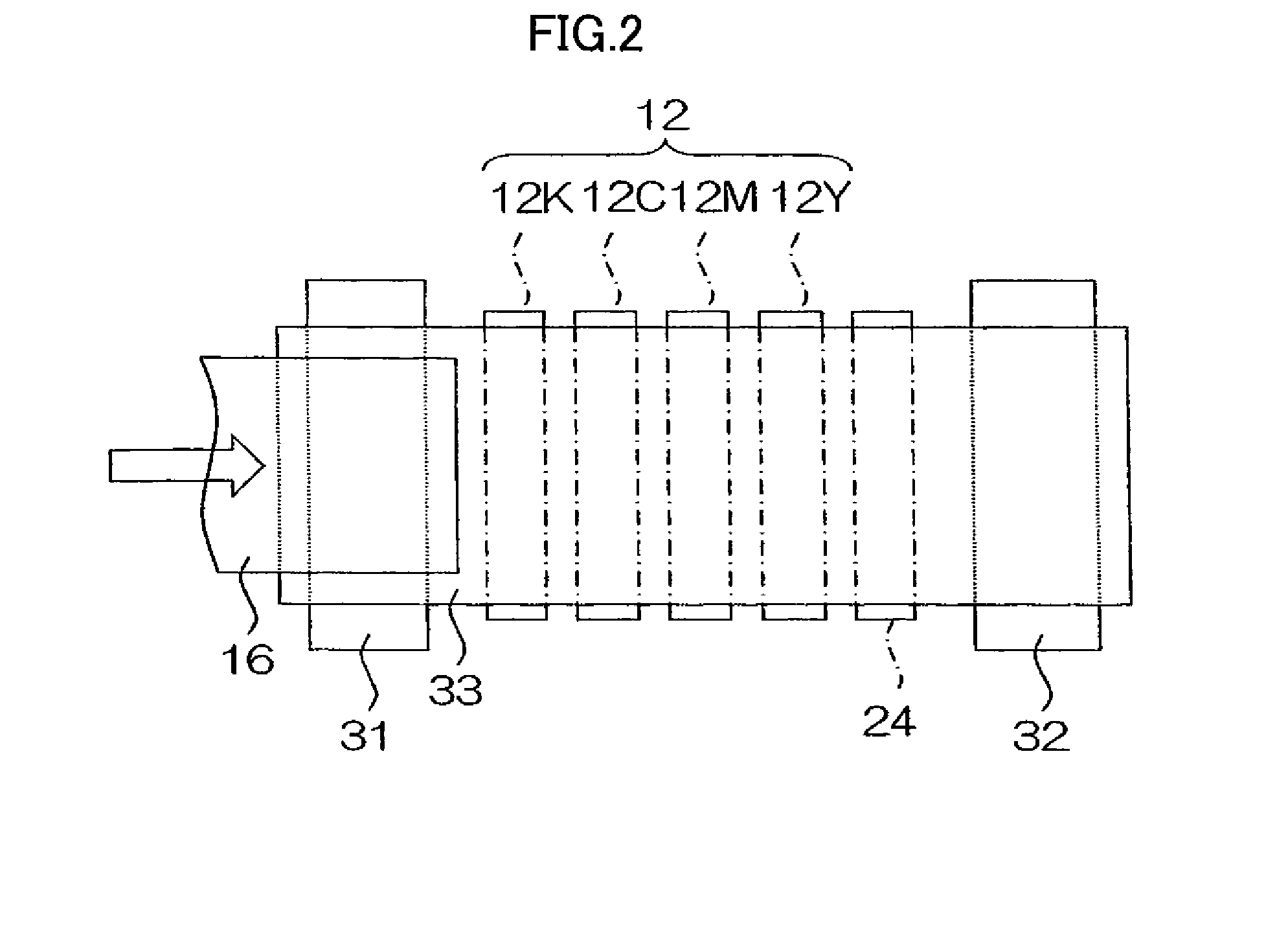

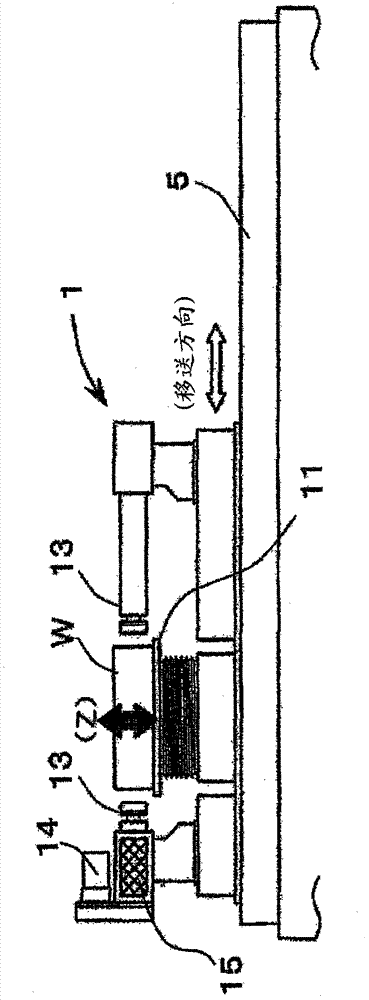

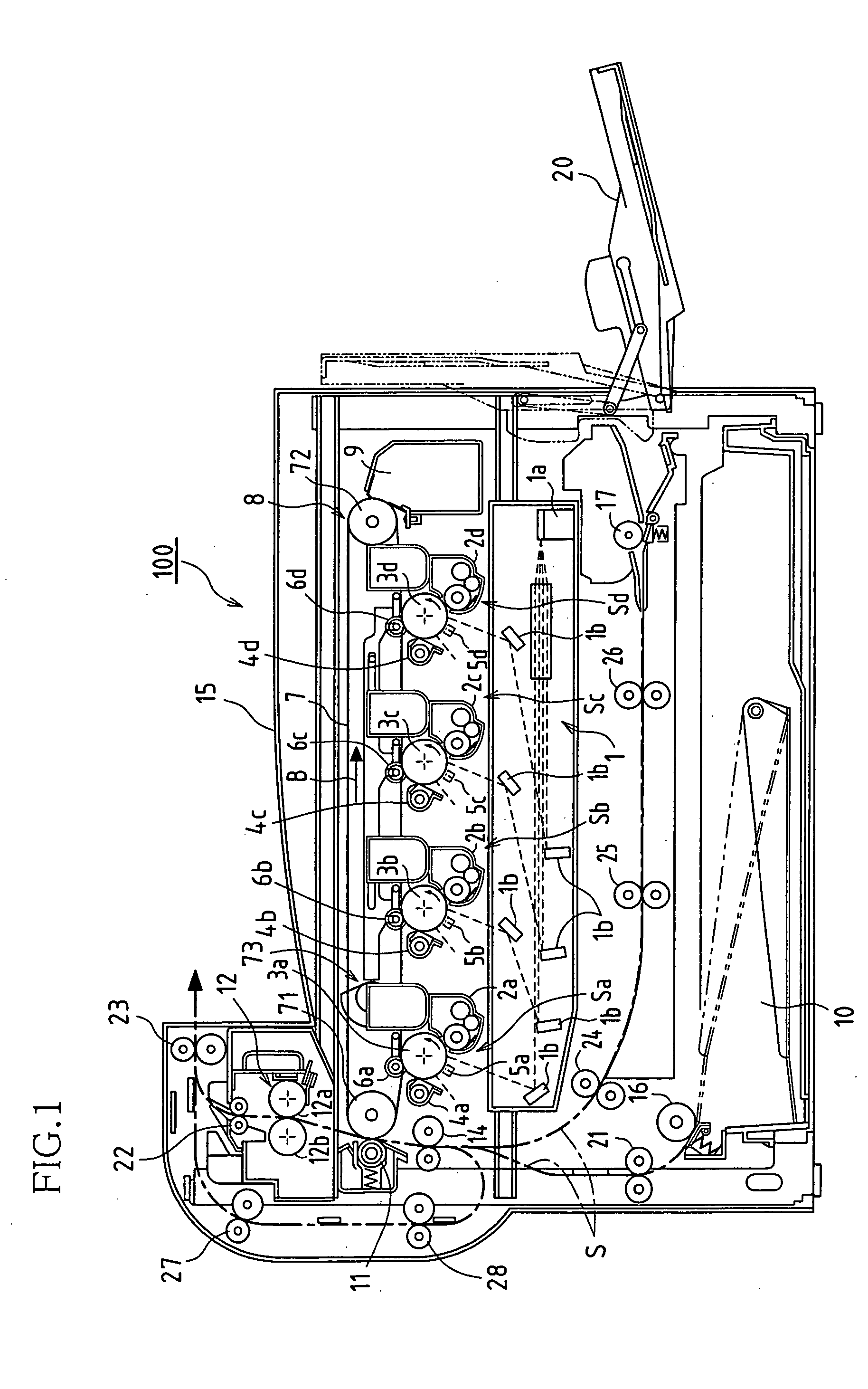

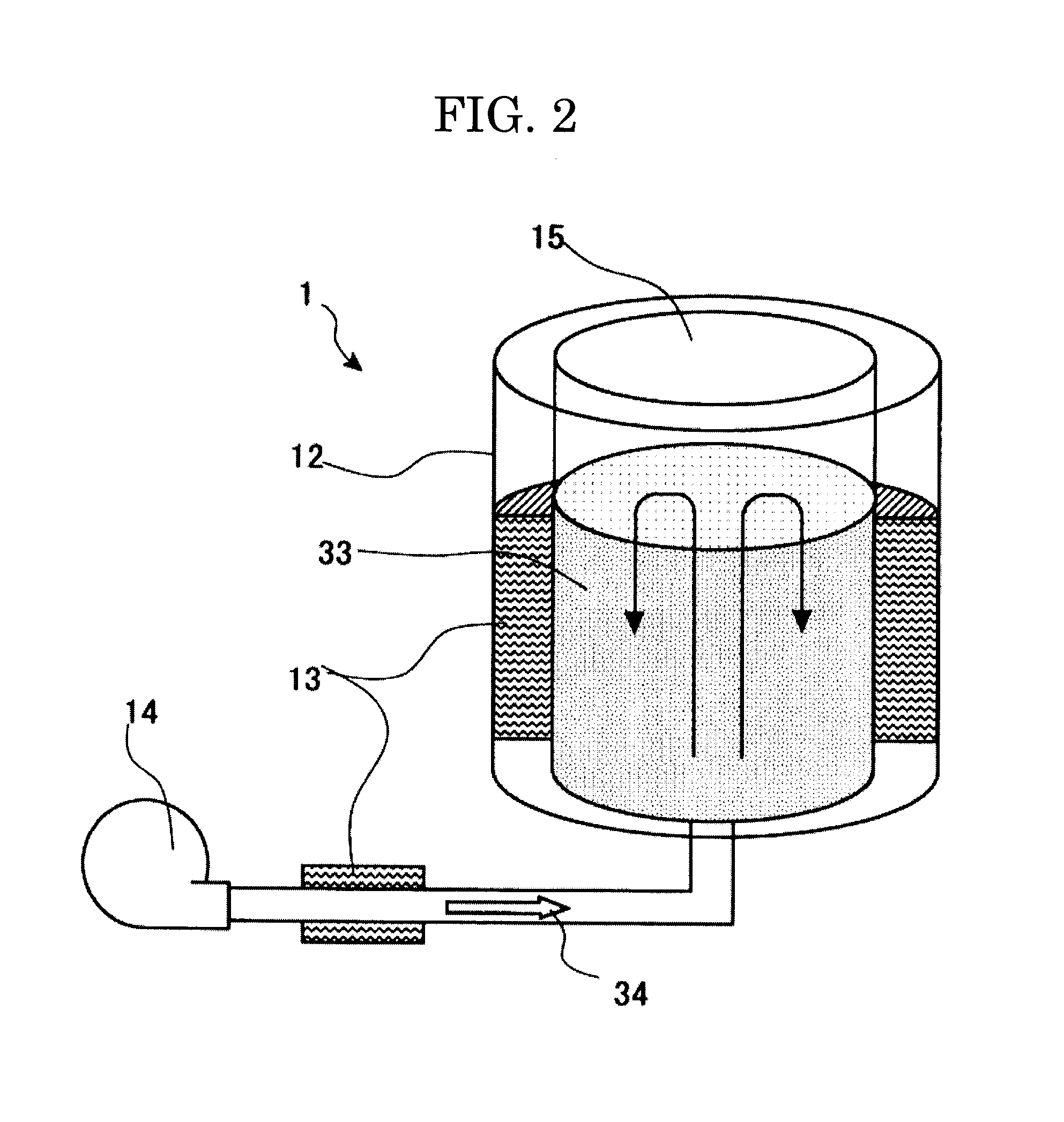

Liquid ejection apparatus and liquid ejection surface maintenance method

InactiveUS20080218554A1Prevent surfaceEfficient and reliable removalOther printing apparatusInternal pressureEngineering

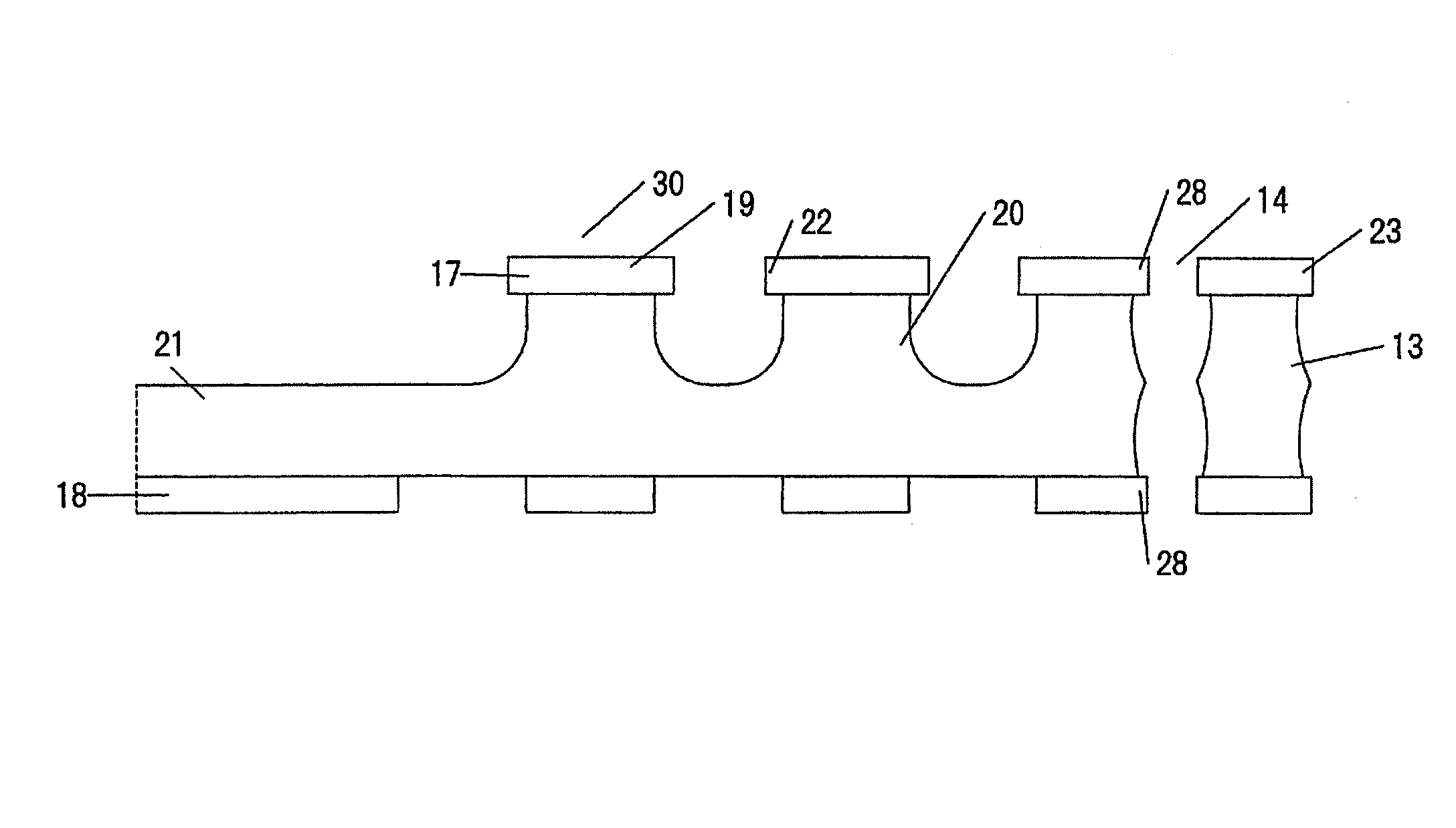

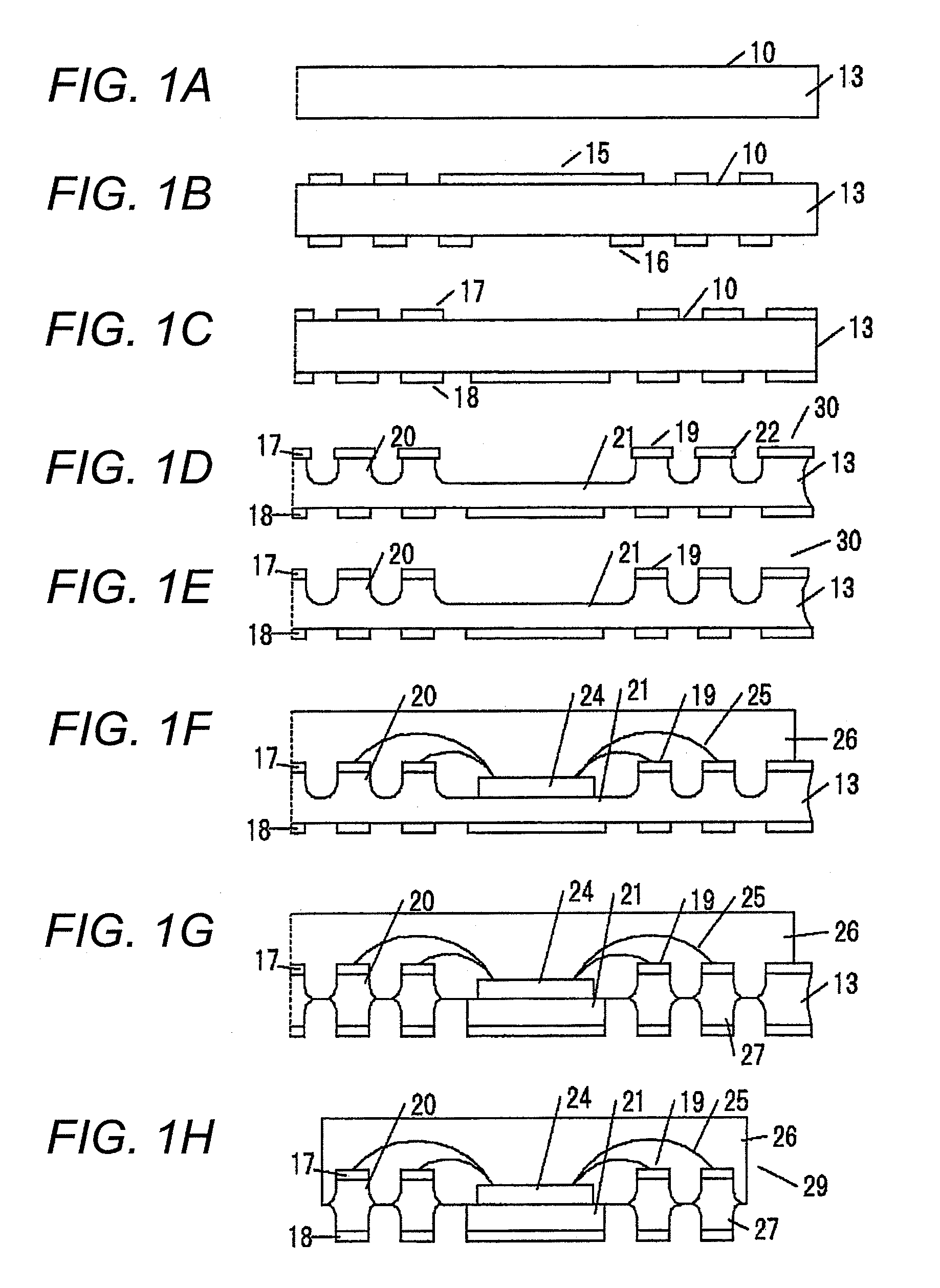

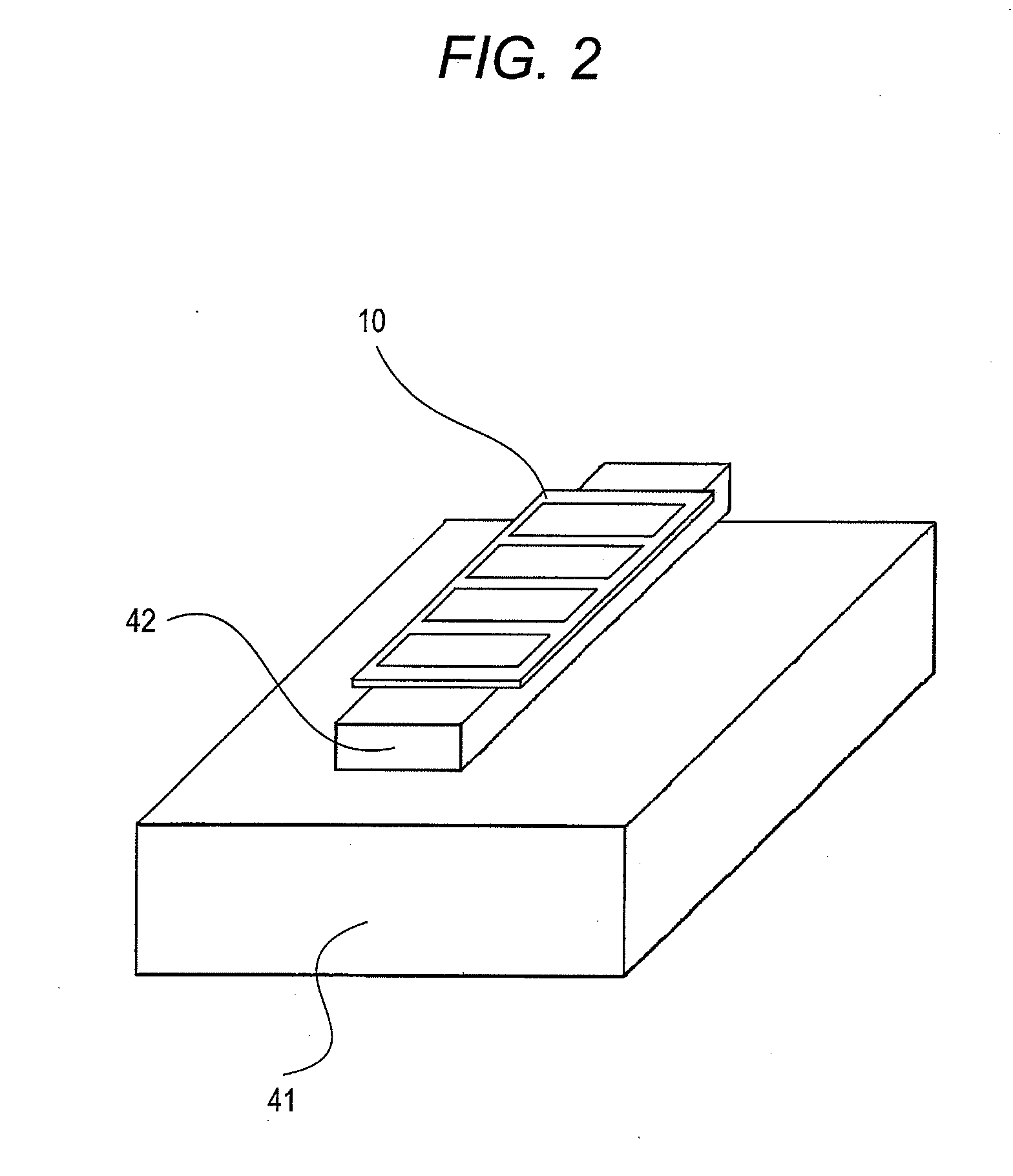

A liquid ejection apparatus includes: a liquid ejection head which includes a nozzle ejecting liquid, a pressure chamber connected to the nozzle and arranged in a liquid ejection surface of the liquid ejection head, and a pressure application device applying pressure to the liquid inside the pressure chamber; an internal pressure adjustment device which adjusts an internal pressure of the liquid ejection head; and a pressure control device which controls the internal pressure adjustment device and the pressure application device so as to spread the liquid over the liquid ejection surface of the liquid ejection head. The internal pressure adjustment device adjusts the internal pressure of the liquid ejection head to a positive pressure so as to still hold the liquid on the nozzle while protruding the liquid from the liquid ejection surface. The pressure application device then applies the pressure to the liquid inside the pressure chamber for a pressure application duration so as not to cause the liquid to be ejected from the nozzle but to flow out the liquid from the nozzle onto the liquid ejection surface, while the internal pressure adjustment device is adjusting the internal pressure to the positive pressure. The pressure application device then stops applying the pressure to the liquid inside the pressure chamber after the pressure application duration, while the internal pressure adjustment device is adjusting the internal pressure to the positive pressure.

Owner:FUJIFILM CORP

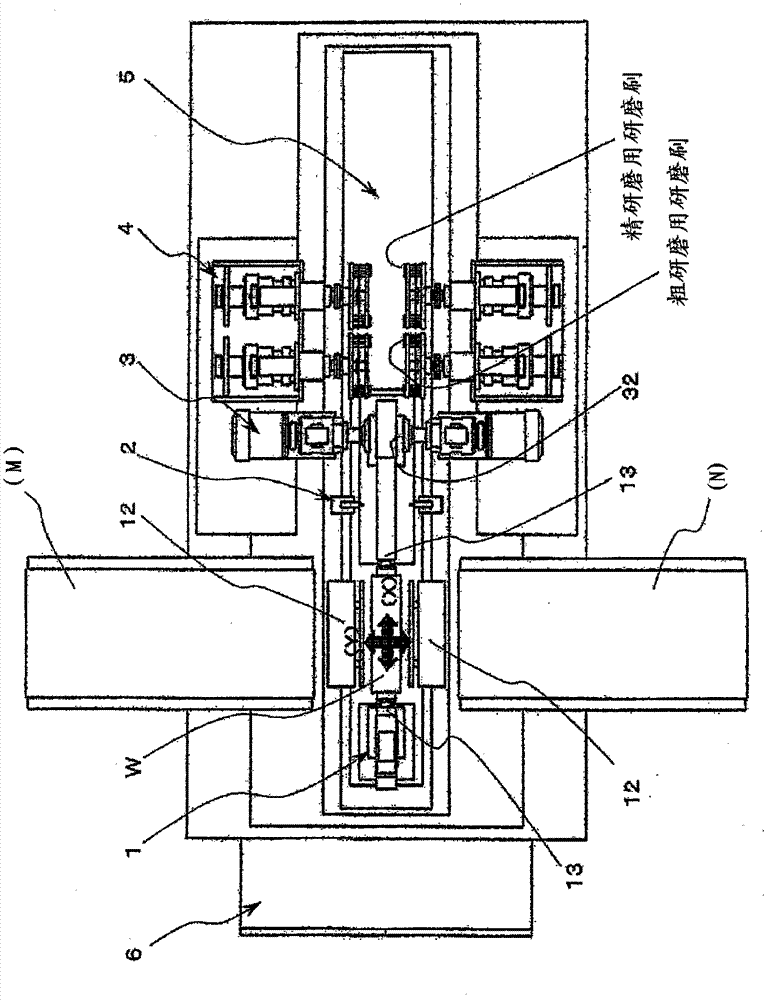

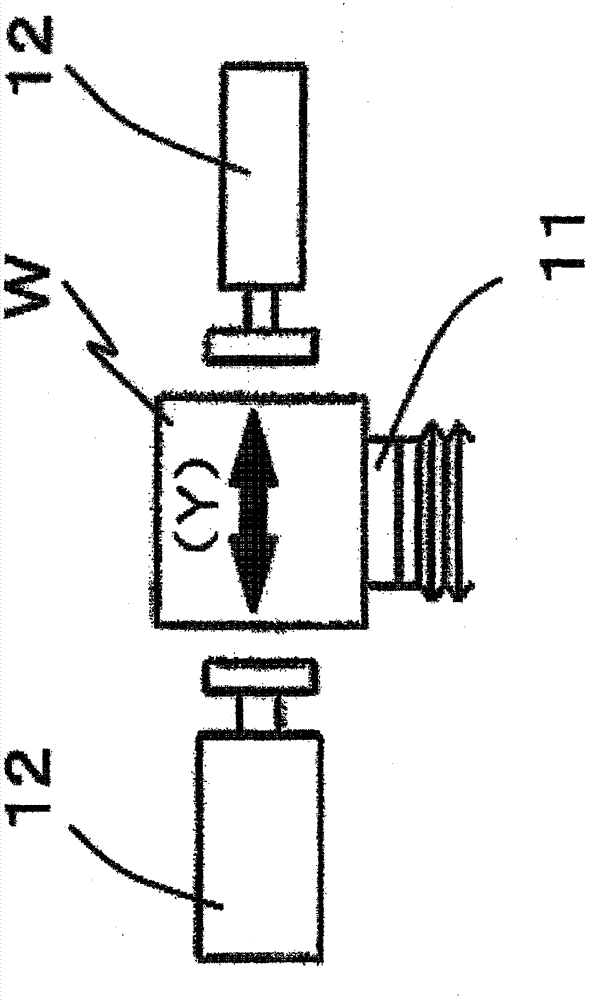

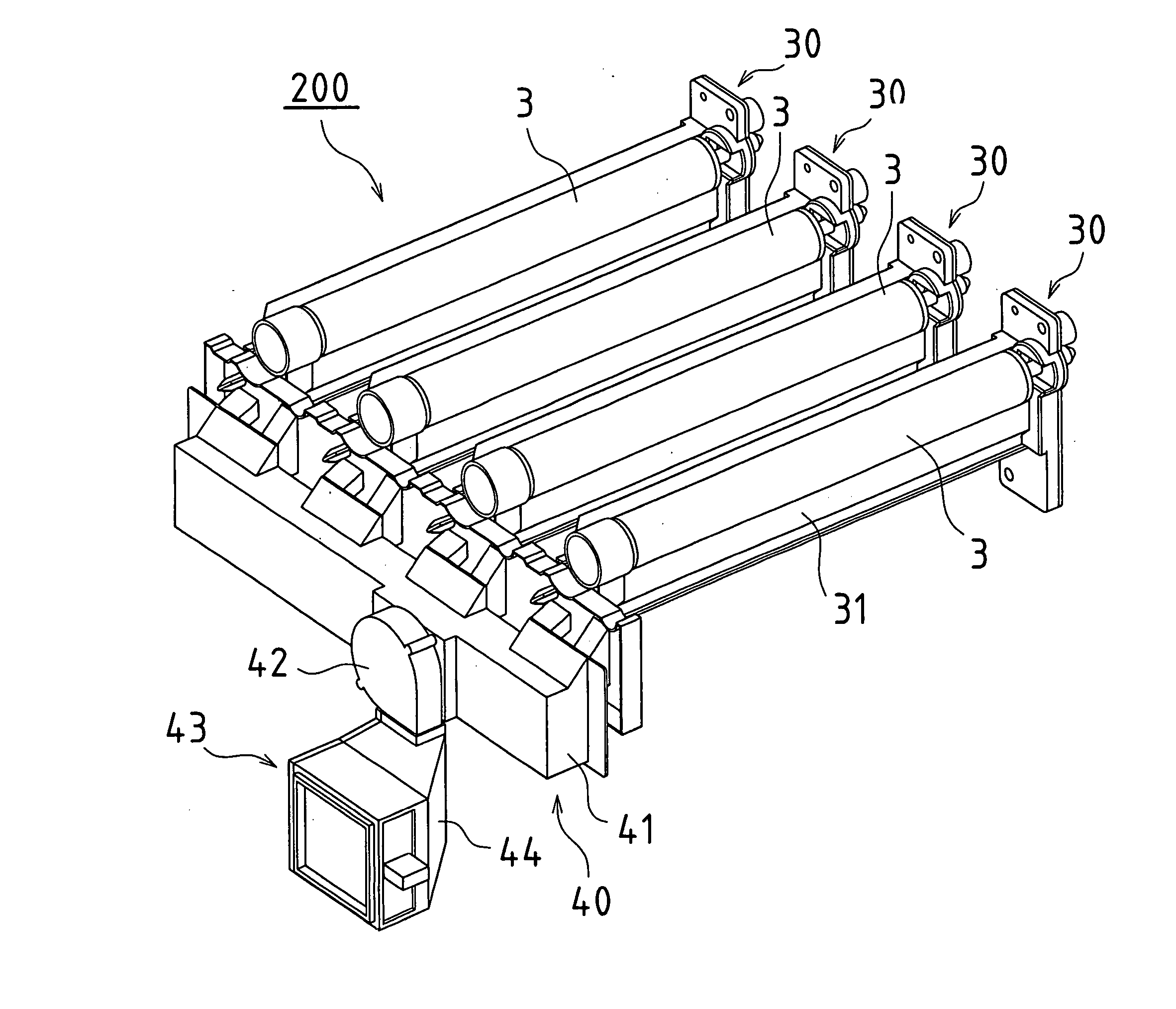

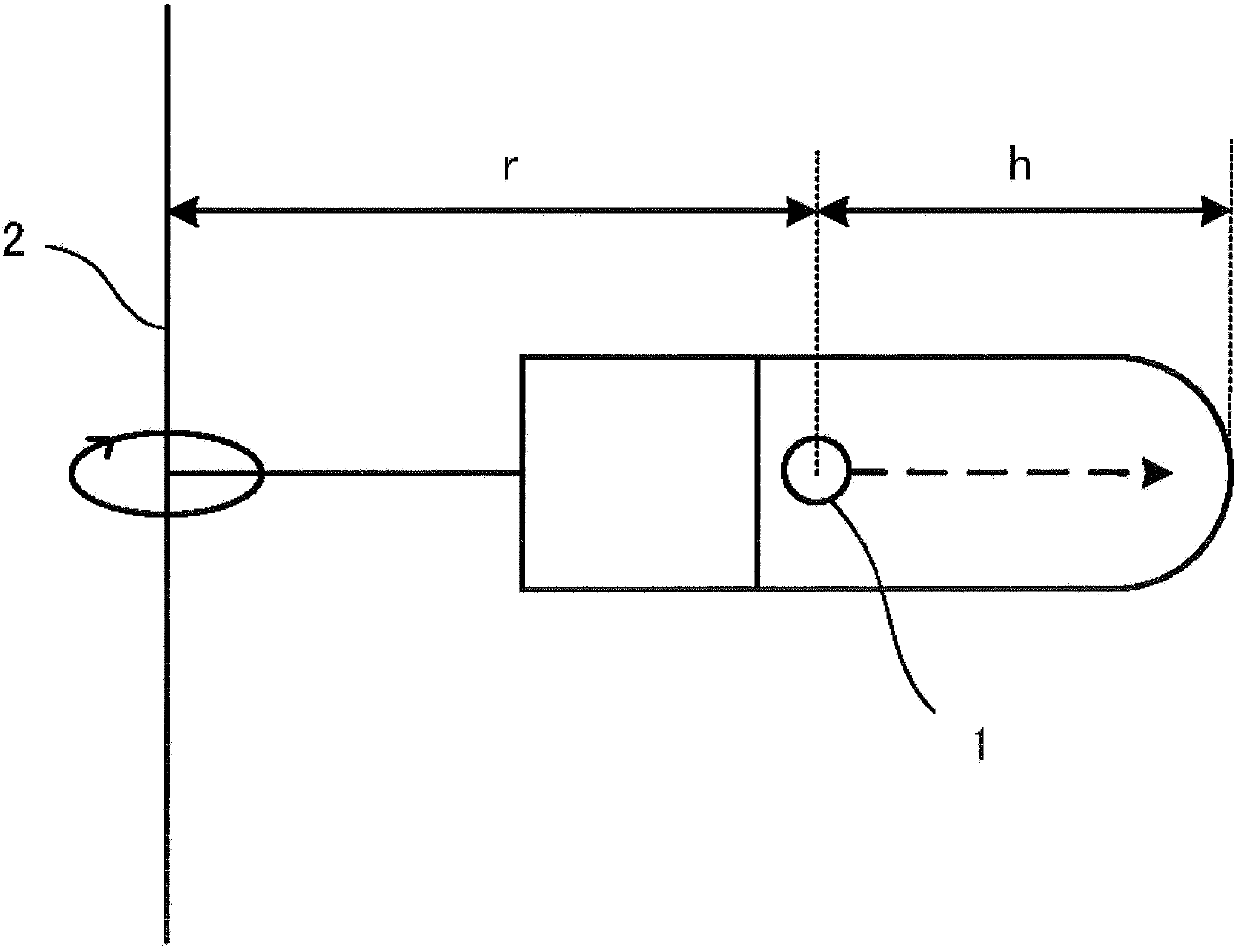

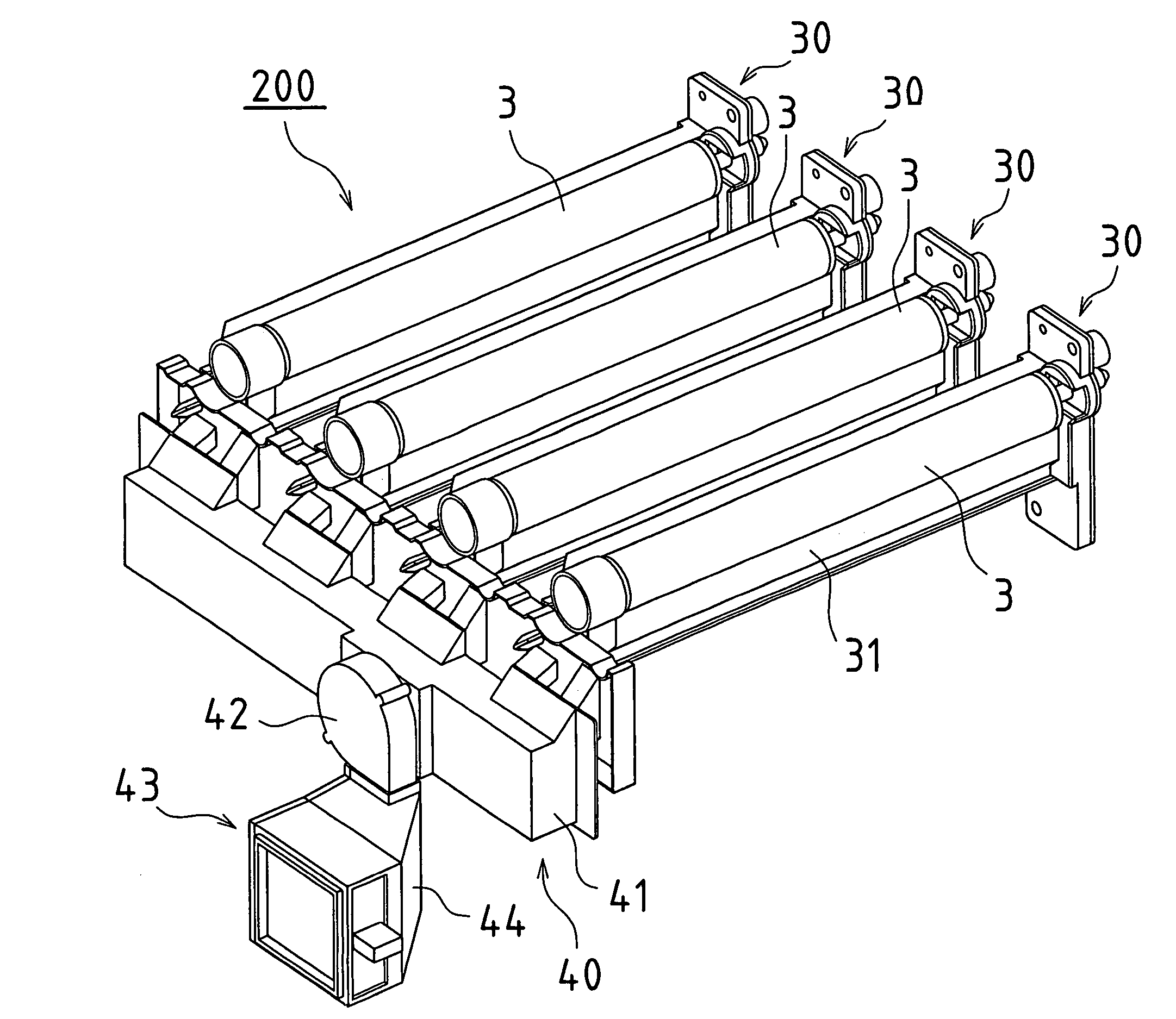

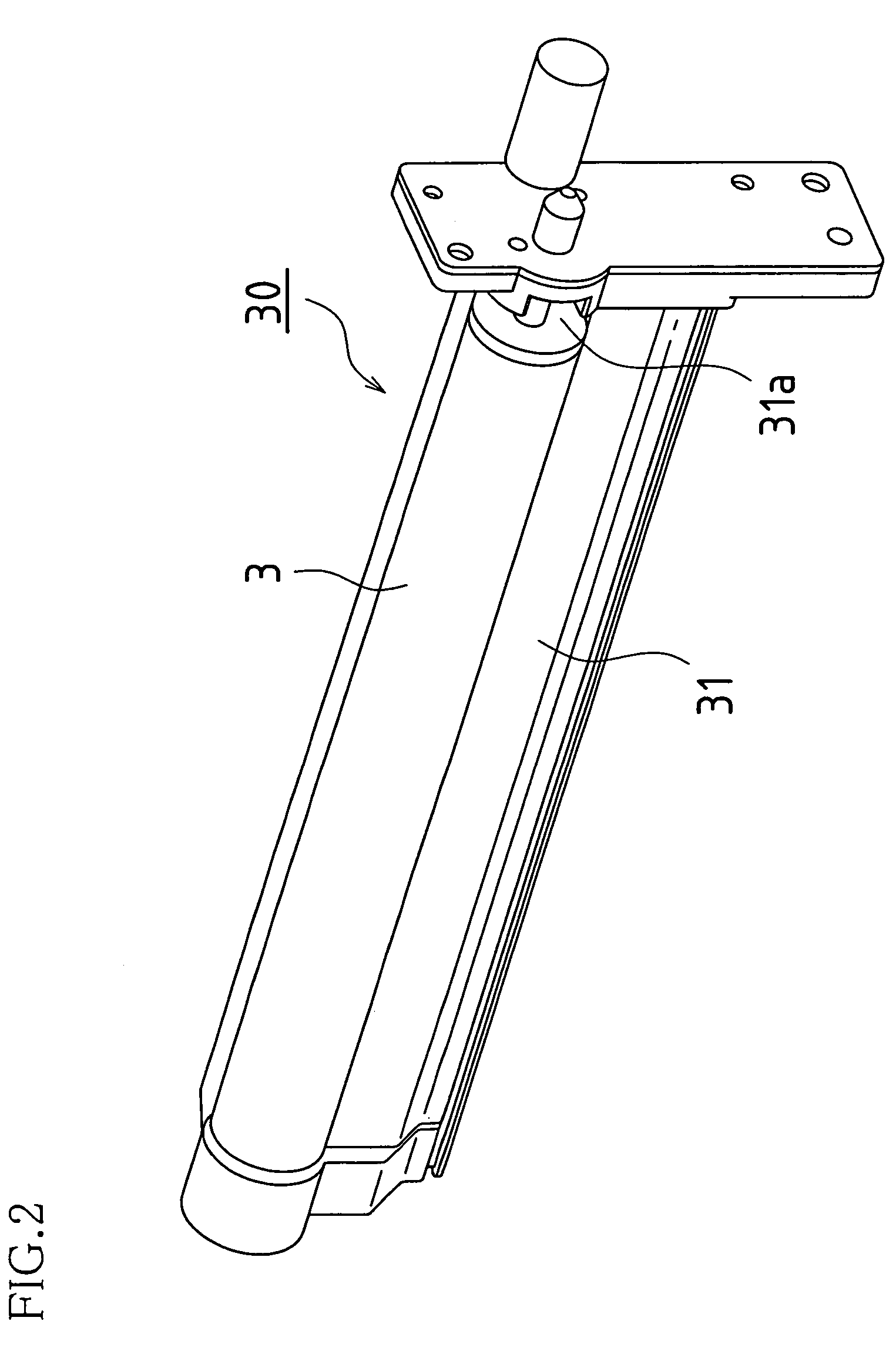

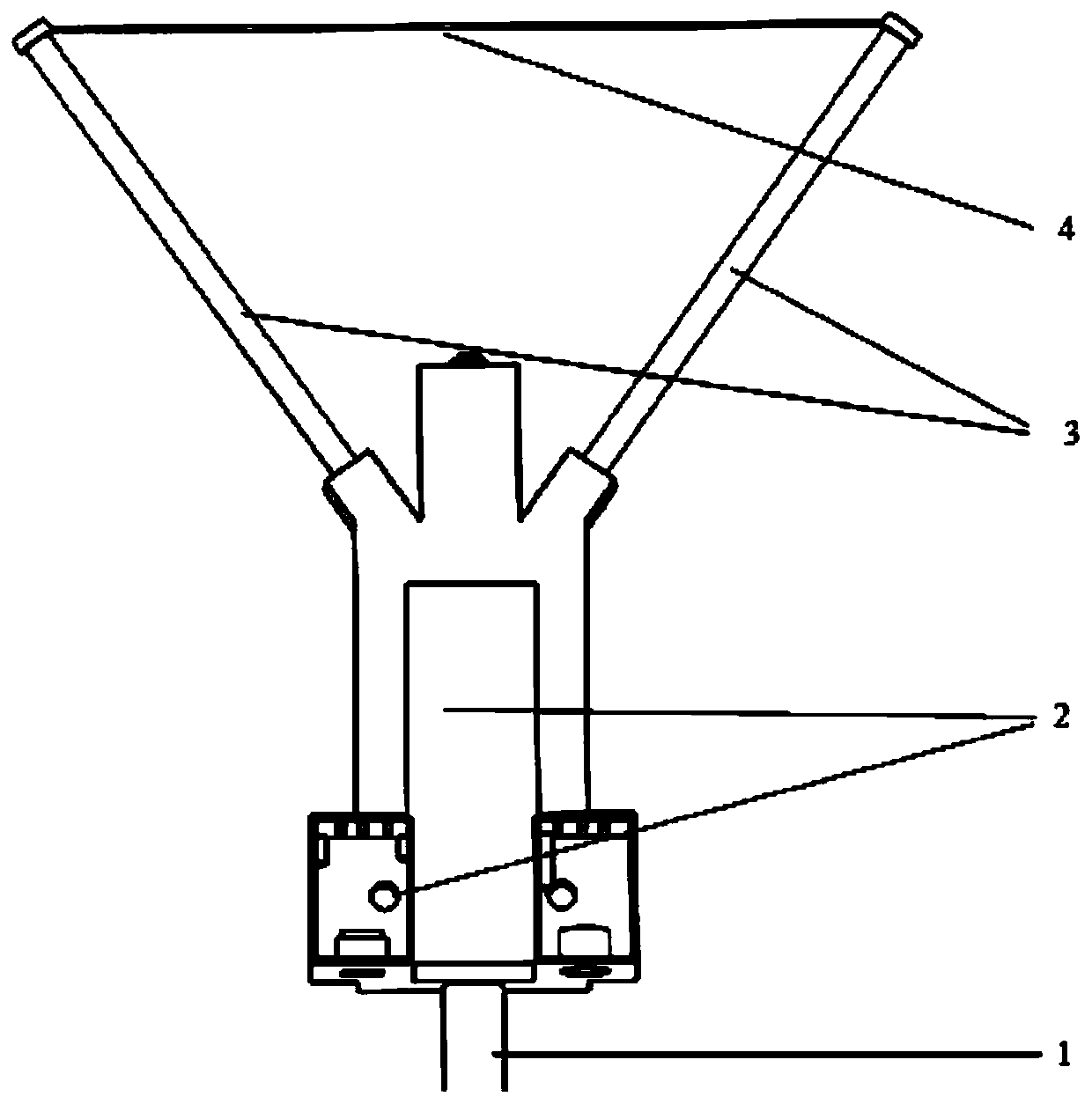

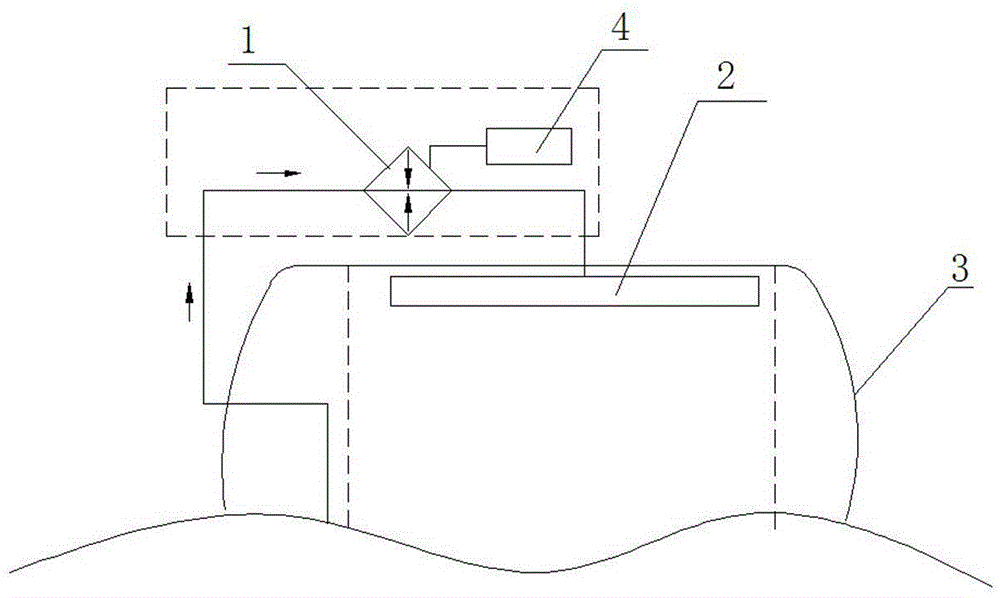

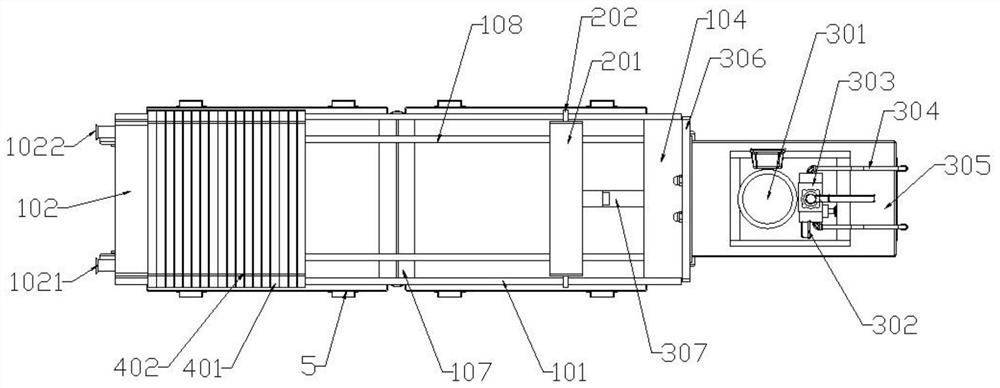

Grinding/polishing device for polygonal column member and grinding/polishing method

ActiveCN102791425AReliable grindingReduce manufacturing costEdge grinding machinesPolishing machinesSurface layerIngot

Provided are: a silicon block grinding / polishing device comprising a grinding function capable of grinding a square column-shaped silicon block within tolerance ranges of +-0.5 mm for the cross-section dimensions thereof and +-0.1 DEG for the perpendicular angles thereof, said block having been formed by cutting a silicon ingot using a wire saw, and comprising a polishing function capable of removing micro cracks in the surface layer of the cut silicon block (W); and a processing method therefor. The device comprises: a holding means (1) that holds the silicon block (W); a measuring means (2) that measures the cross-section dimensions of the silicon block (W); a grinding means (3) that grinds the planar sections (F) and the angular sections (C) of the silicon block (W); a polishing means (4) that polishes the planar sections (F) and the angular sections (C) of the silicon block (W) which has completed grinding and removes micro cracks; a transfer means (5) that transfers the holding means (1) holding the silicon block (W), between the measuring means (2), the grinding means (3), and the polishing means (4); and a control means (6) that operates each of the means.

Owner:SINTOKOGIO LTD

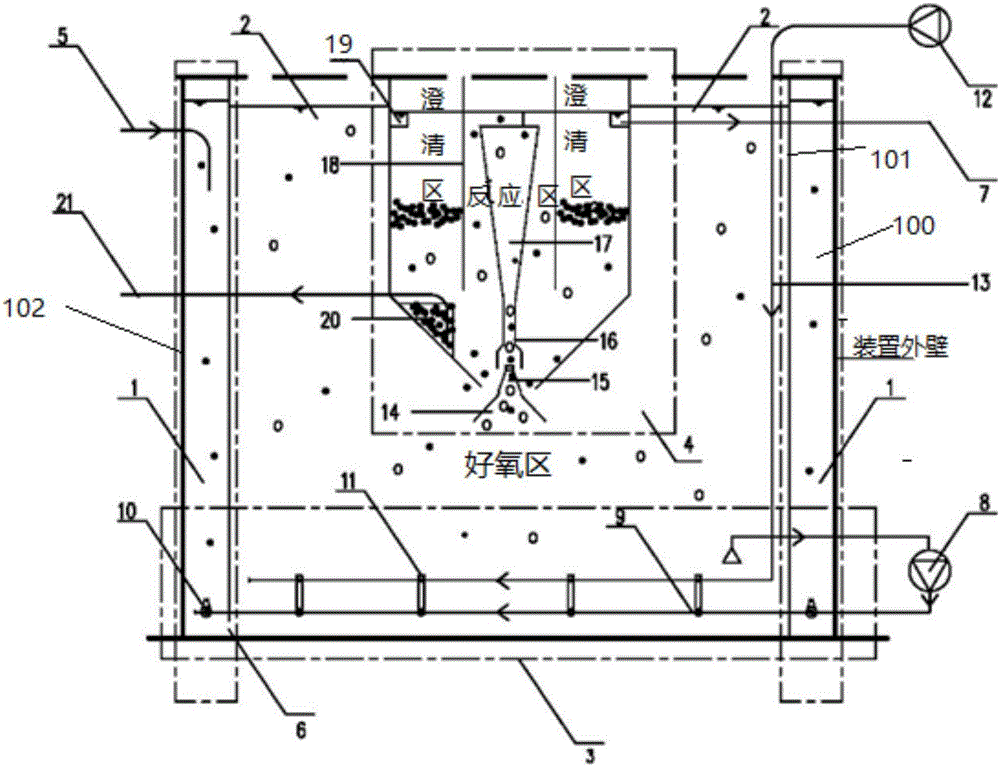

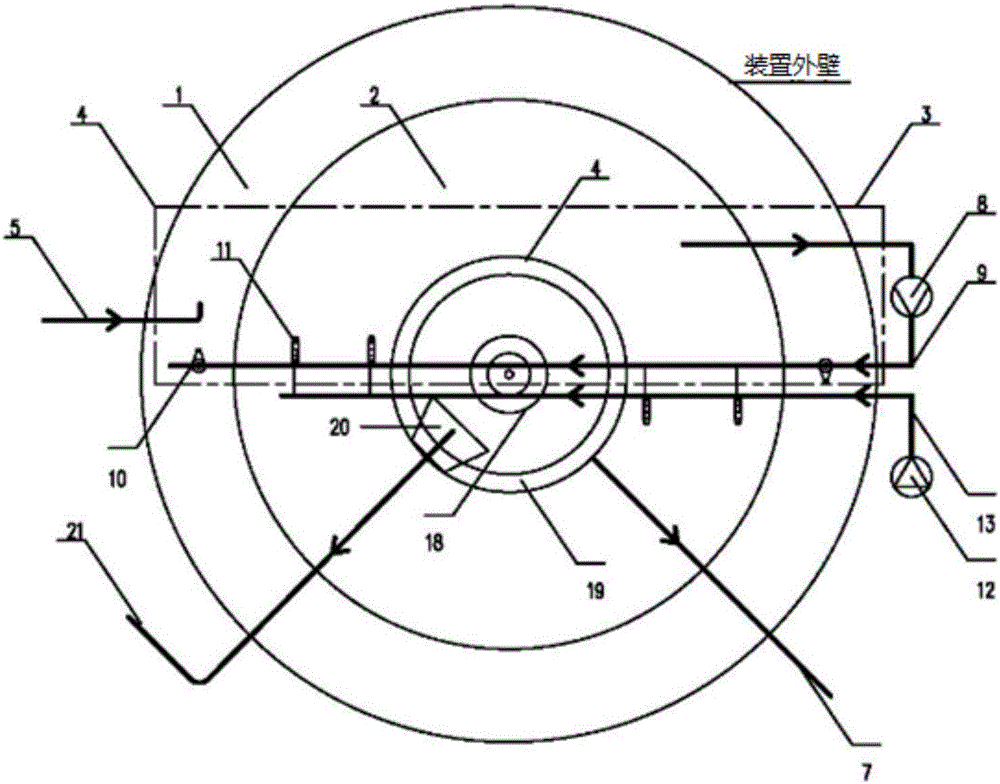

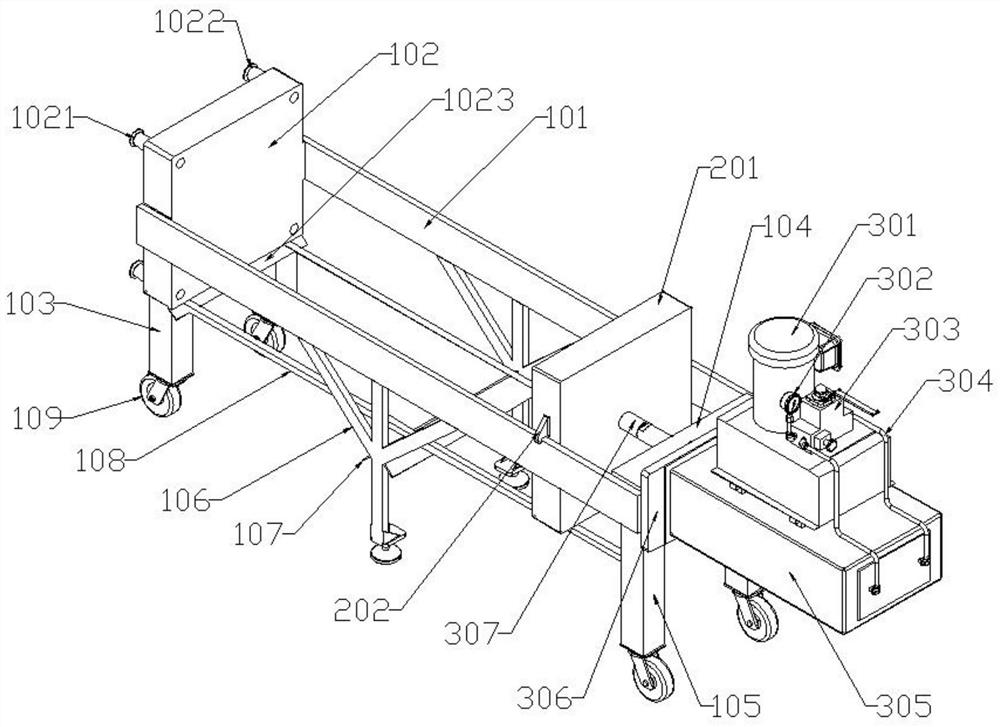

Organic wastewater coupling type integrated treatment device

ActiveCN106830315AAchieving a one-piece structureSmall footprintWater contaminantsBiological treatment apparatusActivated sludgeReflux

The invention discloses an organic wastewater coupling type integrated treatment device. The treatment device comprises a tank body which is provided with hollow annular walls, wherein the annular walls include an inner wall and an outer wall; anoxic zones are arranged in spaces in the annular walls; the inner wall surrounds the middle of the tank body to form an aerobic zone; the aerobic zone and the aerobic zone are communicated through water through holes; and an aeration reflux device is located at the bottoms of the anoxic zones and the aerobic zone, and a solid-liquid separation device is arranged in the center of the upper part of the aerobic zone. According to the organic wastewater coupling type integrated treatment device, aerobic-anoxic and hydraulic clarification processes are coupled, and the aeration of the aerobic zone, the reflux of mixed liquid from the aerobic zone to the anoxic zones and the stirring of the anoxic zones are simultaneously finished by virtue of the aeration reflux device; the solid-liquid separation device for the mixed liquid in the aerobic zone and activated sludge is lifted by virtue of gas stripping and negative pressure; and meanwhile, the activated sludge is naturally refluxed to the aerobic zone by virtue of a specific gravity difference of the sludge and water, so as to form the circulating of activated sludge residues. The organic wastewater coupling type integrated treatment device is high in integration degree, low in energy consumption, efficient and reliable, and occupies a small area.

Owner:崔炜 +1

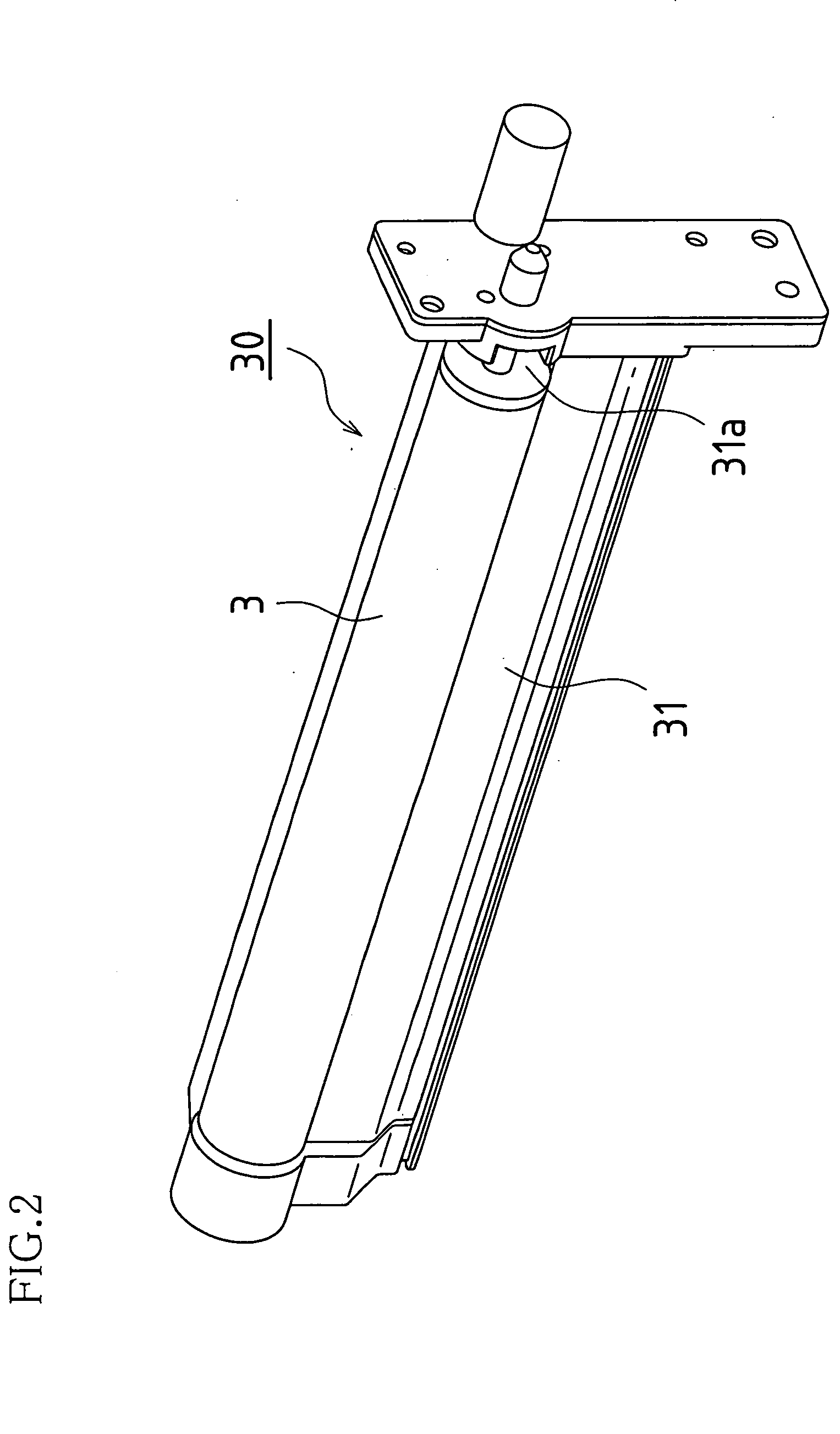

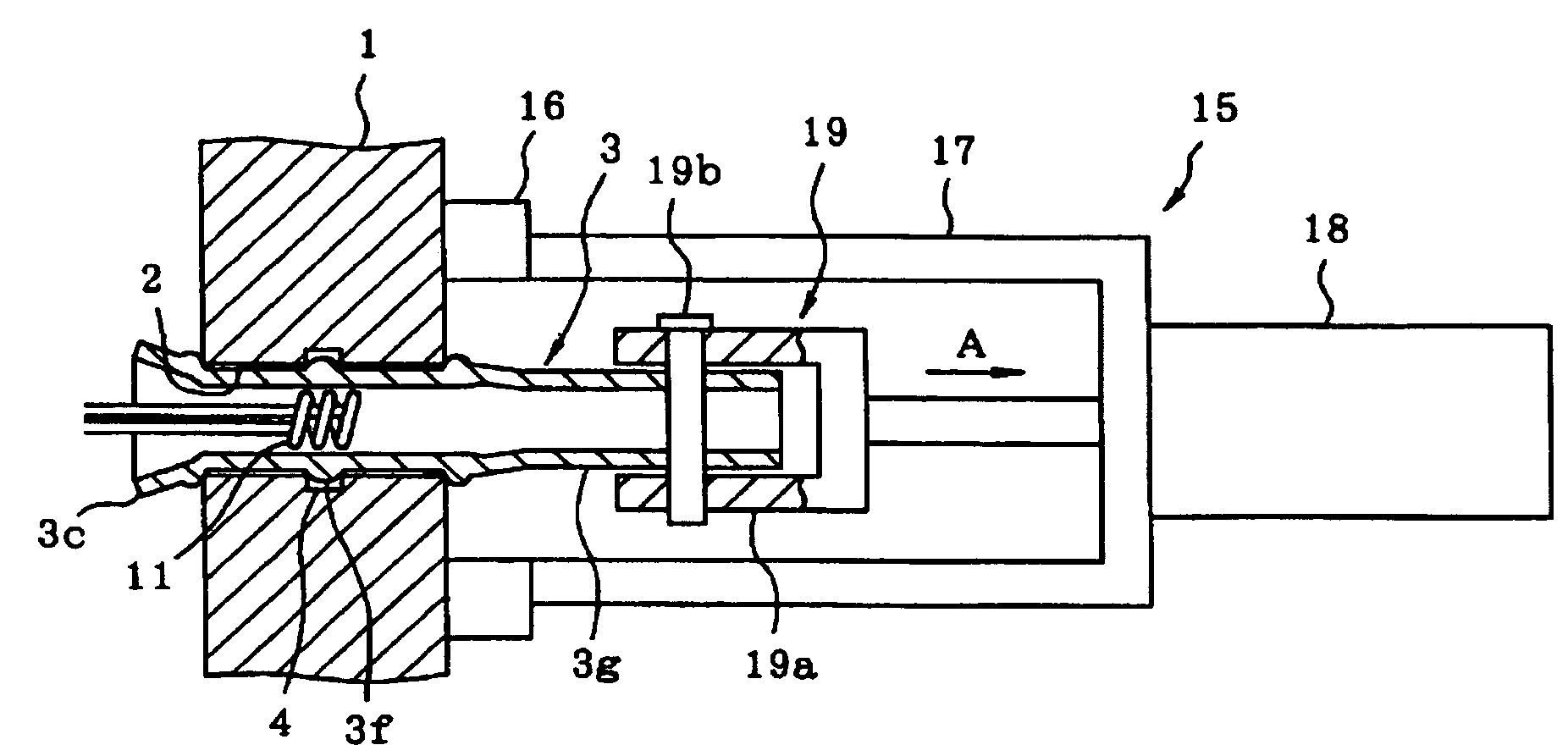

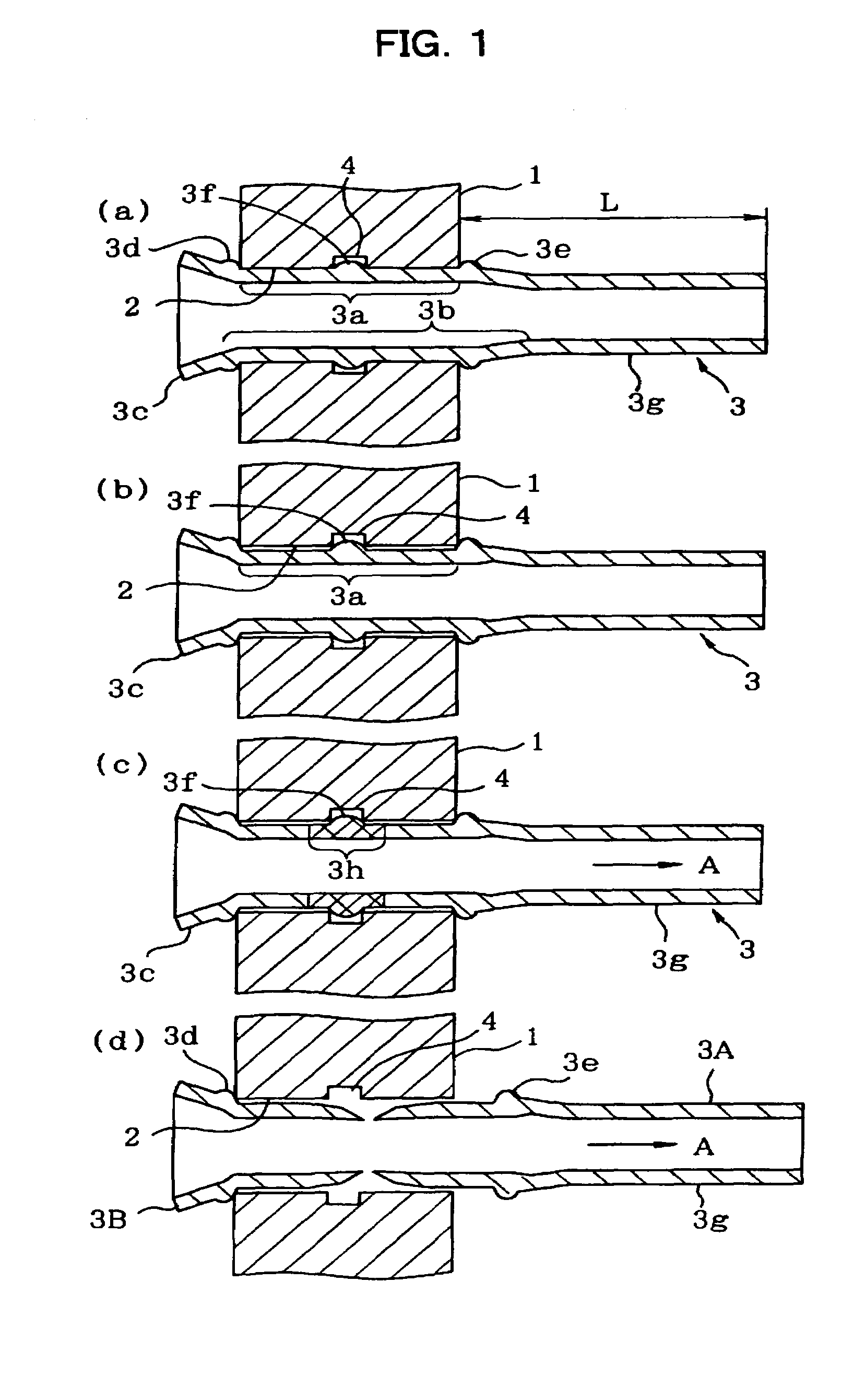

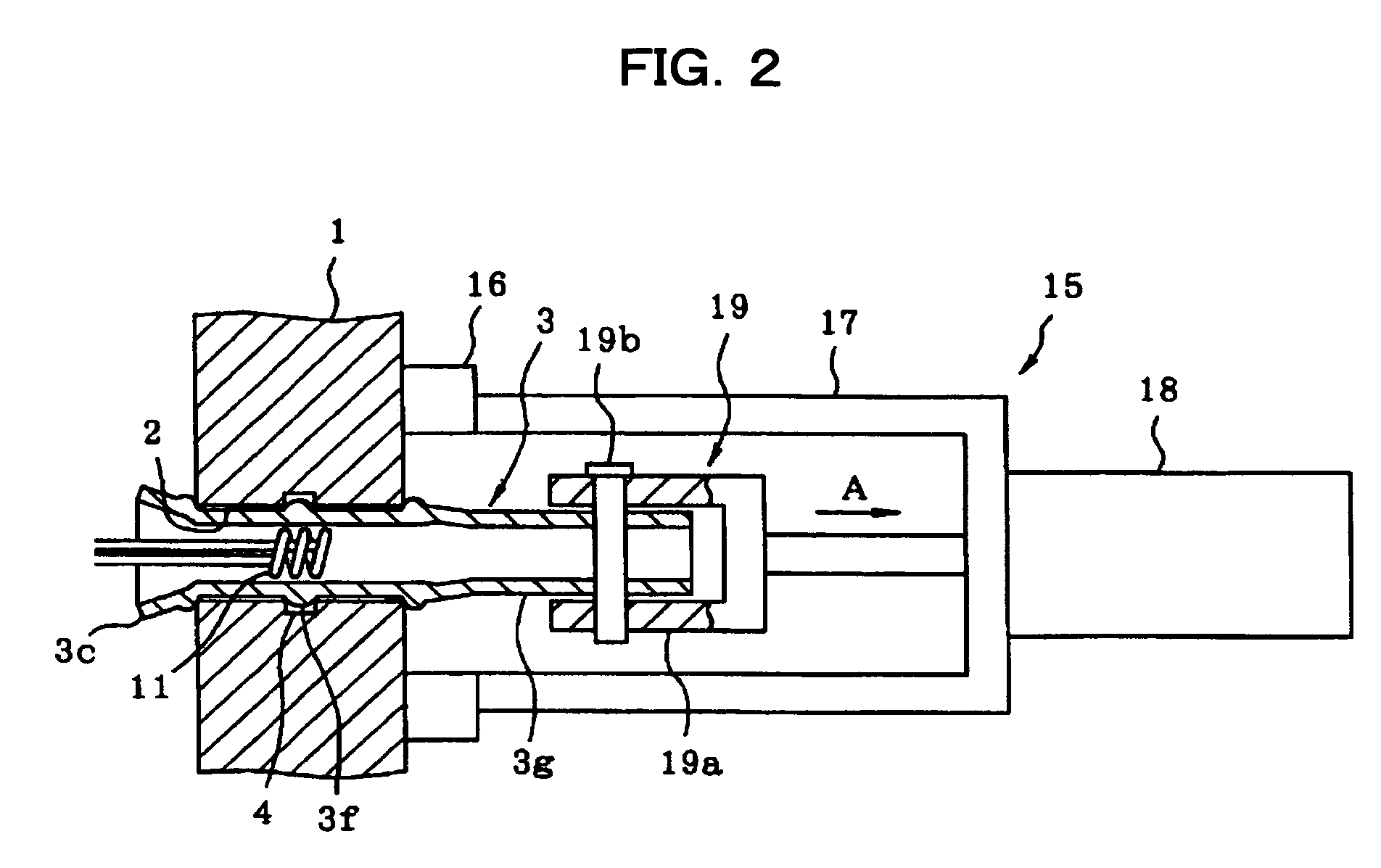

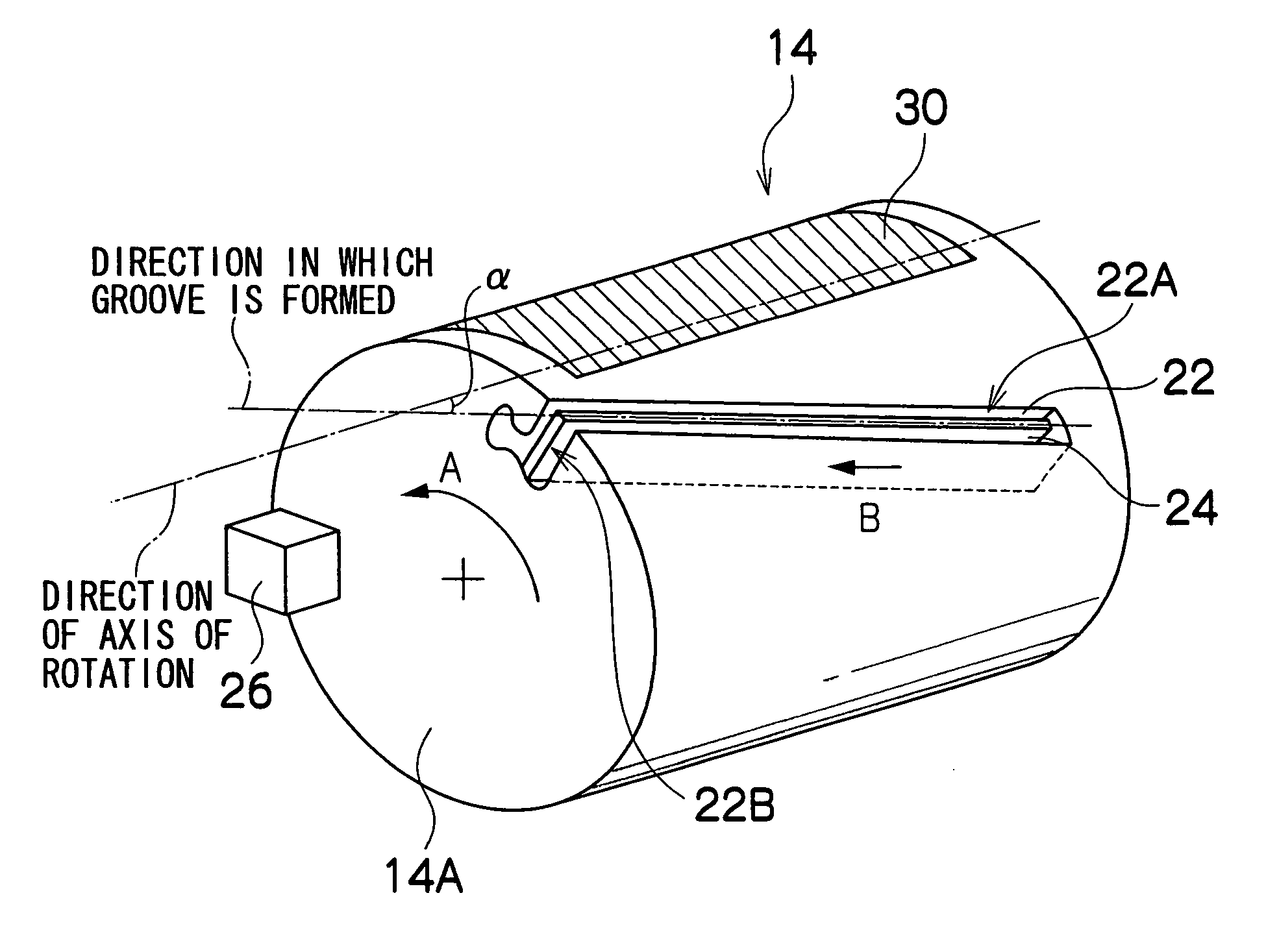

Removing method of tube

ActiveUS20050235473A1Easily pull out and removeReduce the overall diameterDischarge tube luminescnet screensAssembly machinesEngineering

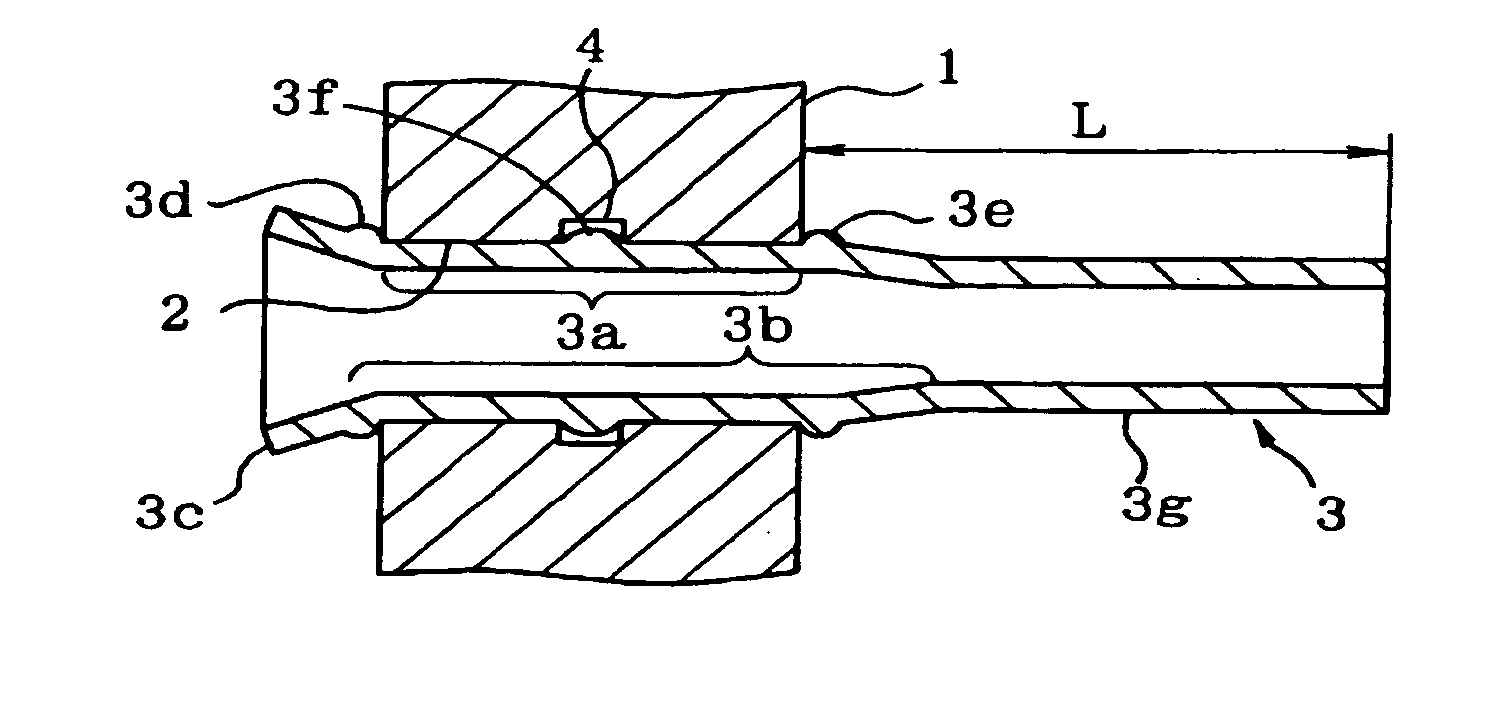

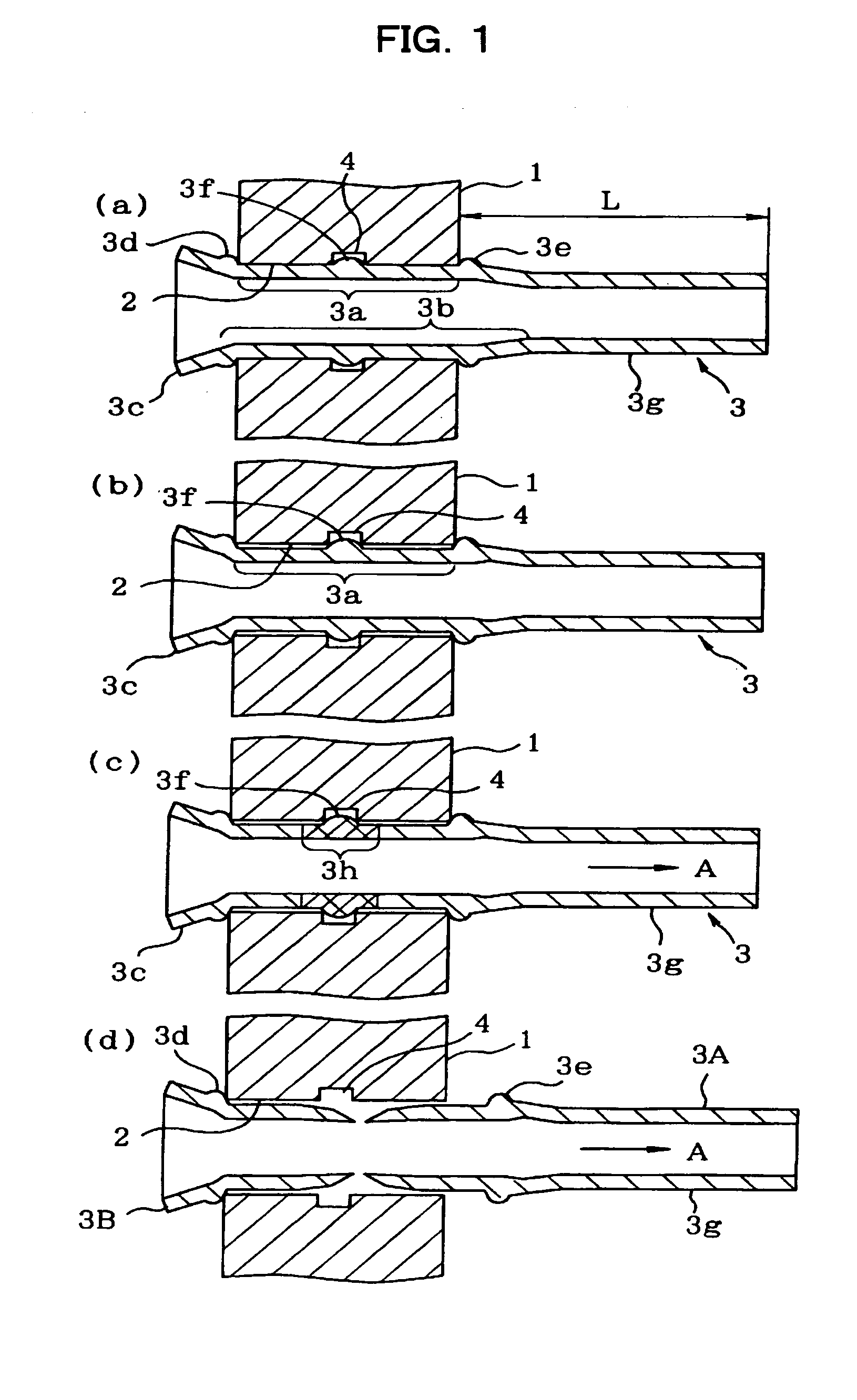

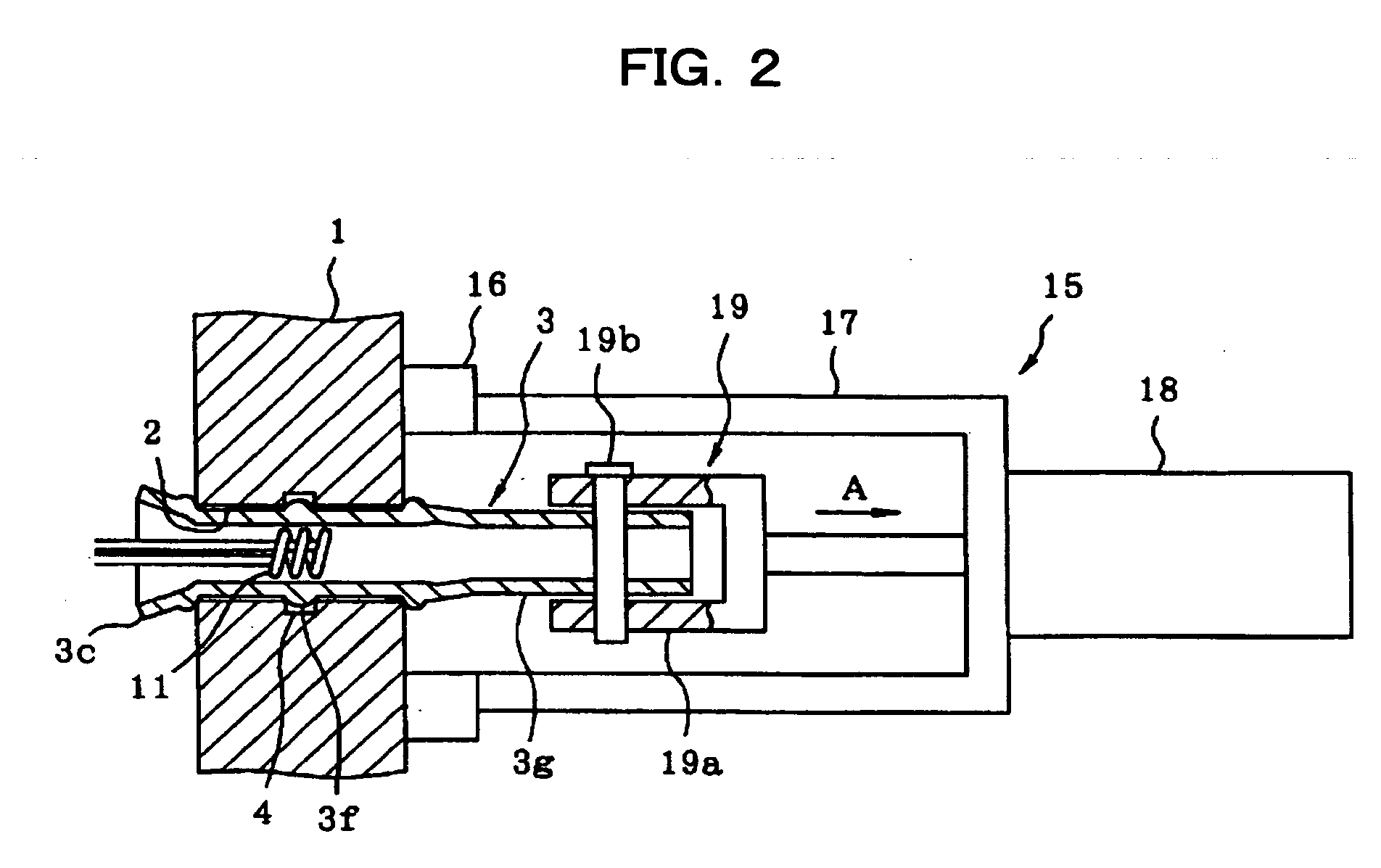

The present invention provides a removing method of a tube. Upon removing a tube 3 increased in diameter and fixed to a tube-sheet 1, an inserted portion 3a which is fixed to a tube-hole 2 of the tube-sheet 1 is heated and then cooled, thereby reducing its diameter. The inserted portion 3a is loosened from the tube-hole 2. Then, a region 3h opposed to a groove 4 formed in an inner circumference of the tube-hole is heated to a red-hot state, and the tube 3 is stretched in its axial direction, the red-heated region 3h is stretched to reduce its diameter and cut the region 3h, thereby pulling out the tube 3 from the tube-sheet 1.

Owner:DAI ICHI HIGH FREQUENCY

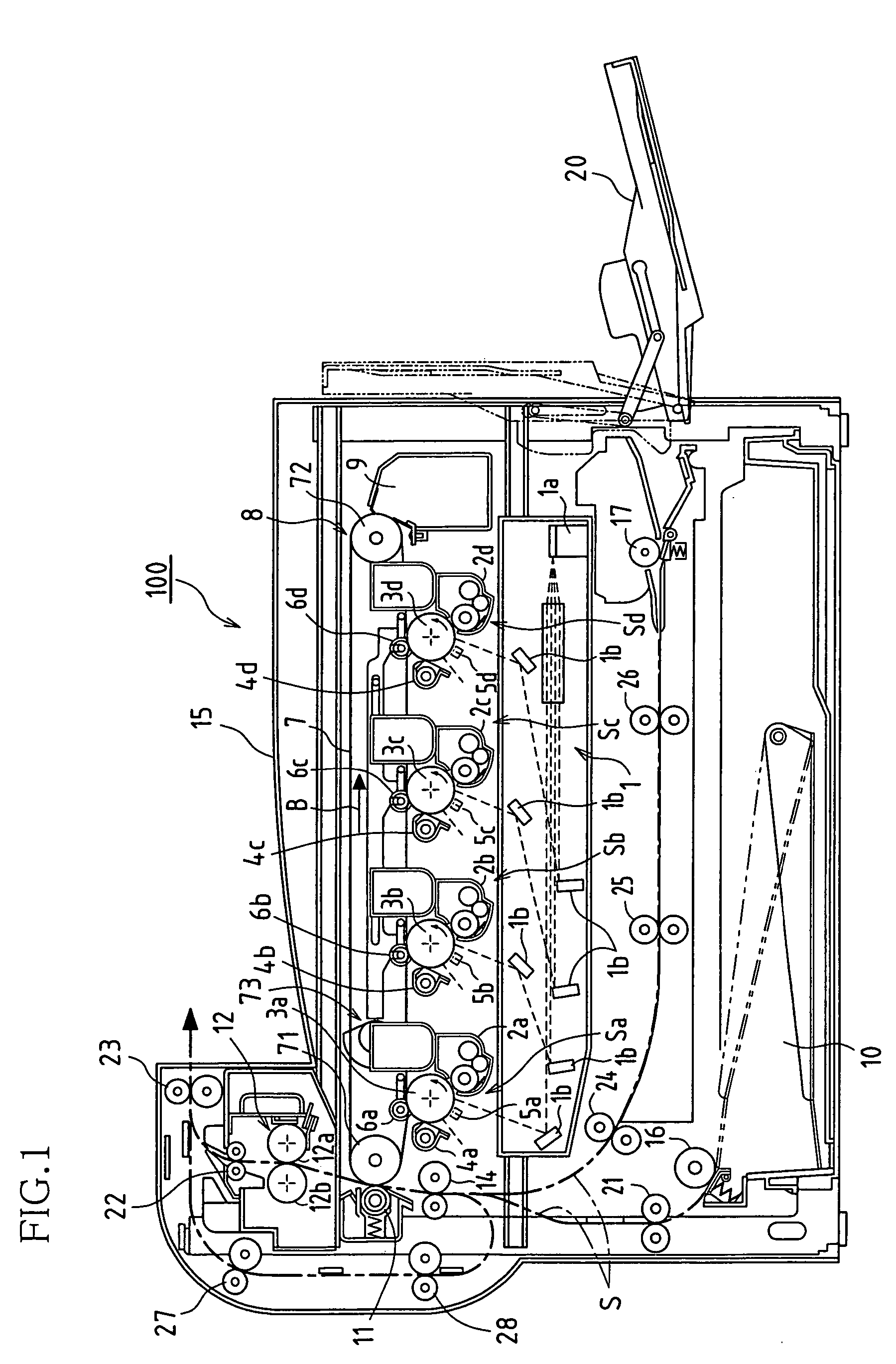

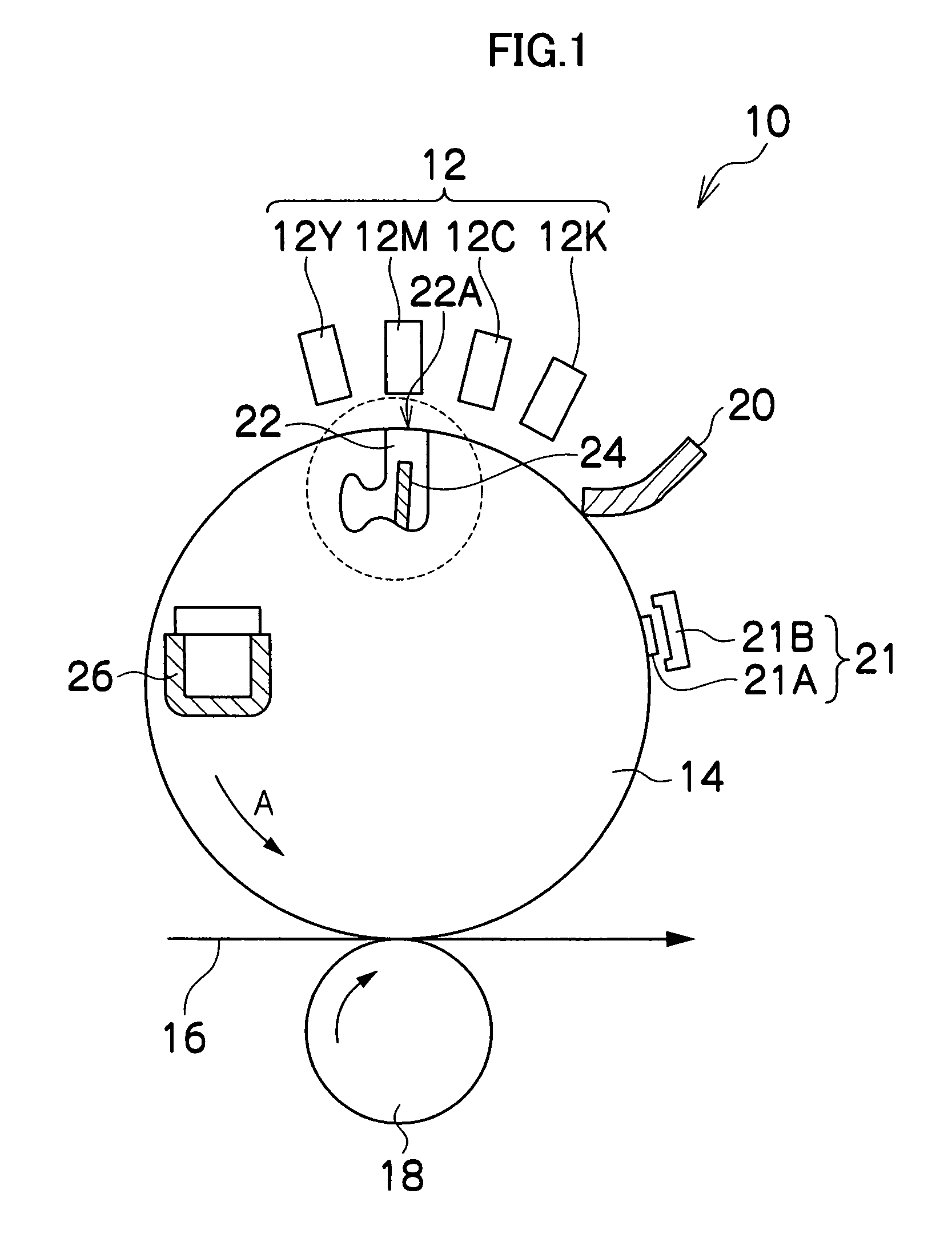

Image forming apparatus

ActiveUS20060024083A1Improve efficiencySpeed up the flowElectrographic process apparatusLatent imageFresh air

In an image forming apparatus that uses a charging unit to charge a photosensitive drum, forms an electrostatic latent image by carrying out image exposure according to image information, and transfers to a paper the electrostatic latent image by developing the electrostatic latent image into a visible image using a developer so that the image information is presented, an exhaust duct 33 for exhausting air that contains ozone produced within a drum unit 30, which includes a photosensitive drum 3 and a charging unit 5, and a duct 32 for taking in air, which draws in fresh air, are provided within the drum unit 30 so that ventilation of the drum unit 30 can be carried out with excellent efficiency.

Owner:SHARP KK

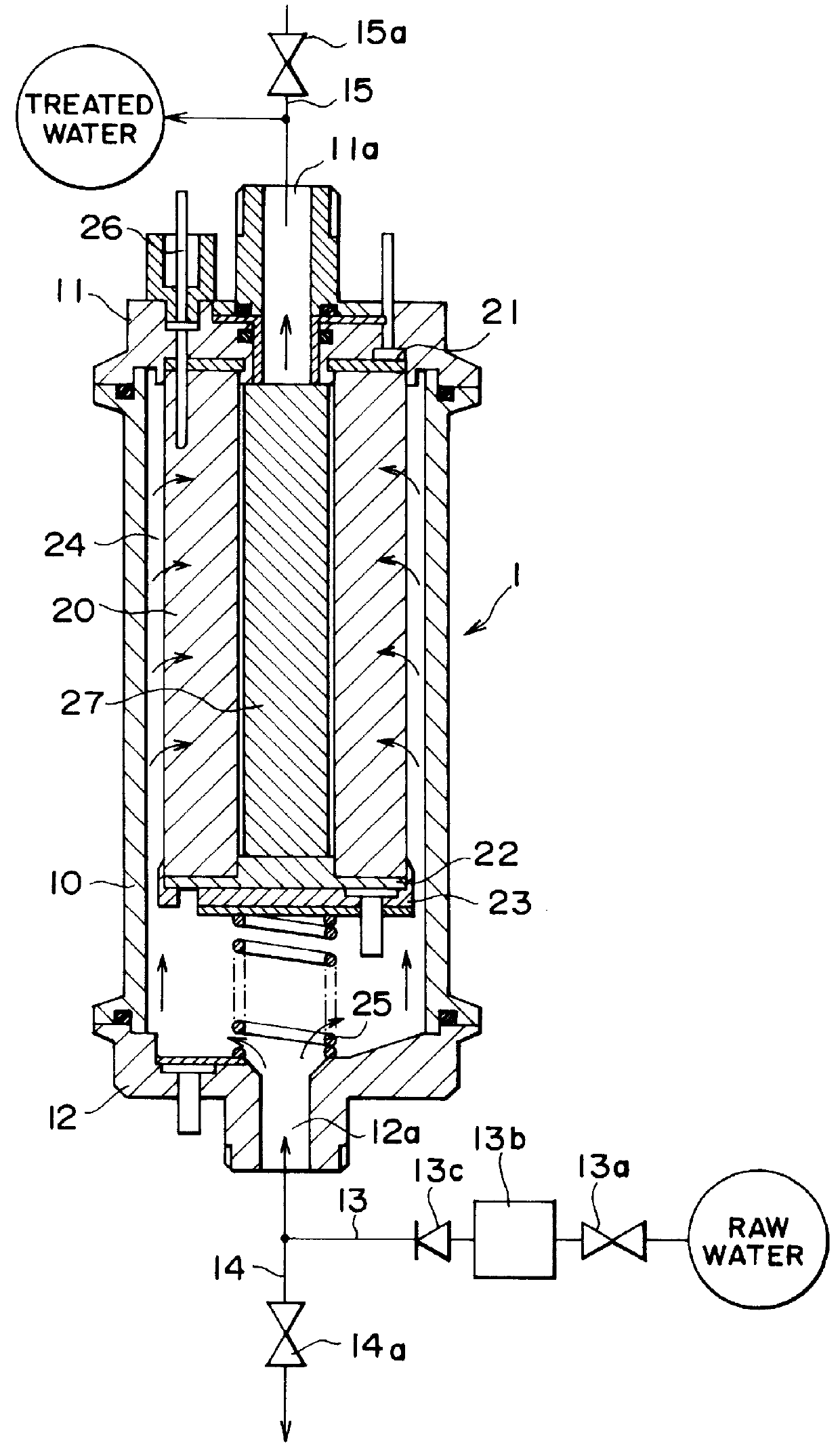

Water purification system and method for efficiently and reliably removing various pollutants different in size

InactiveUS6149826AEfficient and reliable removalAvoid mixingUltrafiltrationTreatment involving filtrationWater flowEnvironmental engineering

In a water purification system in which a first filter (20) is placed in a flow of raw water for filtering the raw water to produce filtered water, a second filter (27) is placed downstream of the first filter for filtering the filtered water. The first filter is conductive and has a plurality of water passages through which the raw water flows. Each of the water passages of the first filter has a first diameter. At intervals, an electric voltage is applied to the first filter to destroy bacteria which is captured by the first filter. The second filter has a plurality of water passages through which the filtered water flows. Each of the water passages of the second filter has a second diameter smaller than the first diameter.

Owner:SANDEN CORP

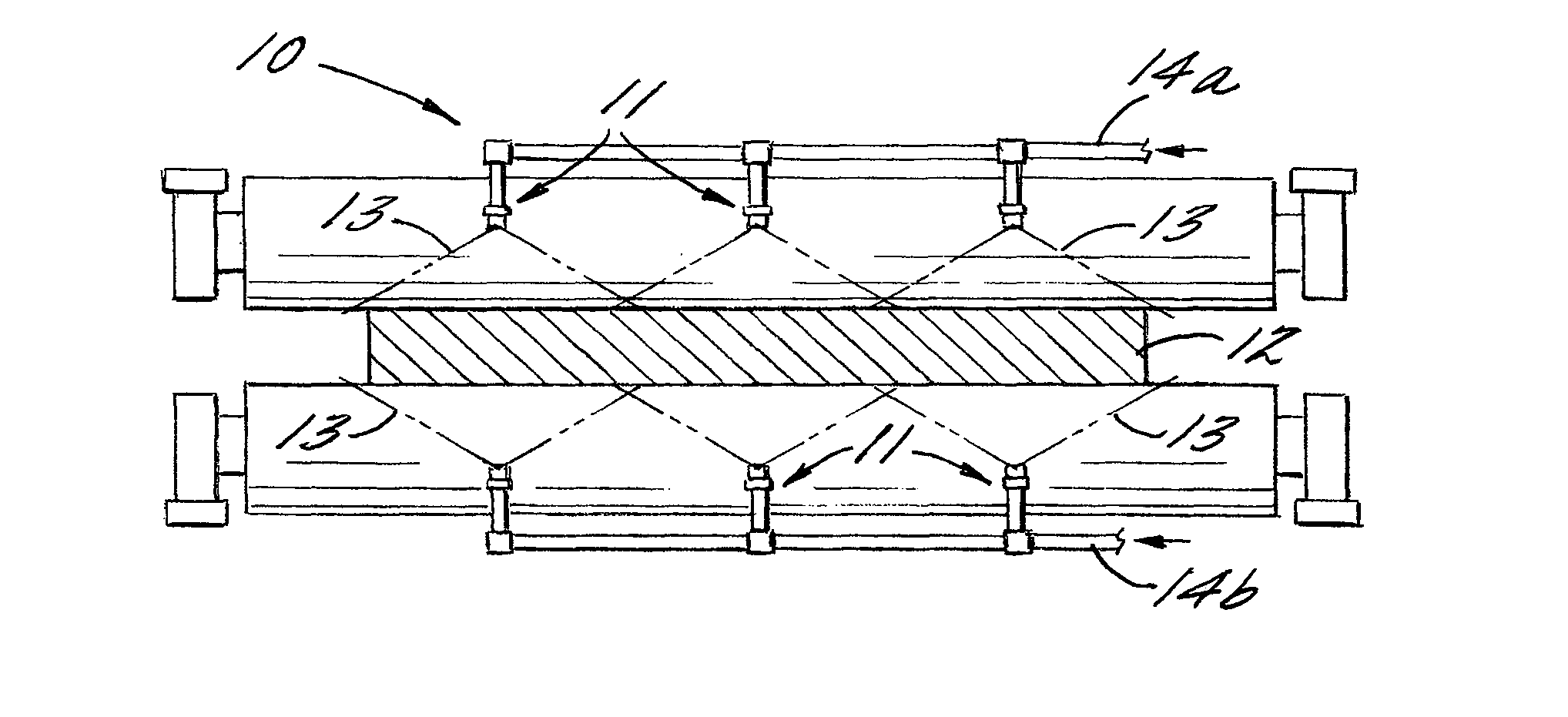

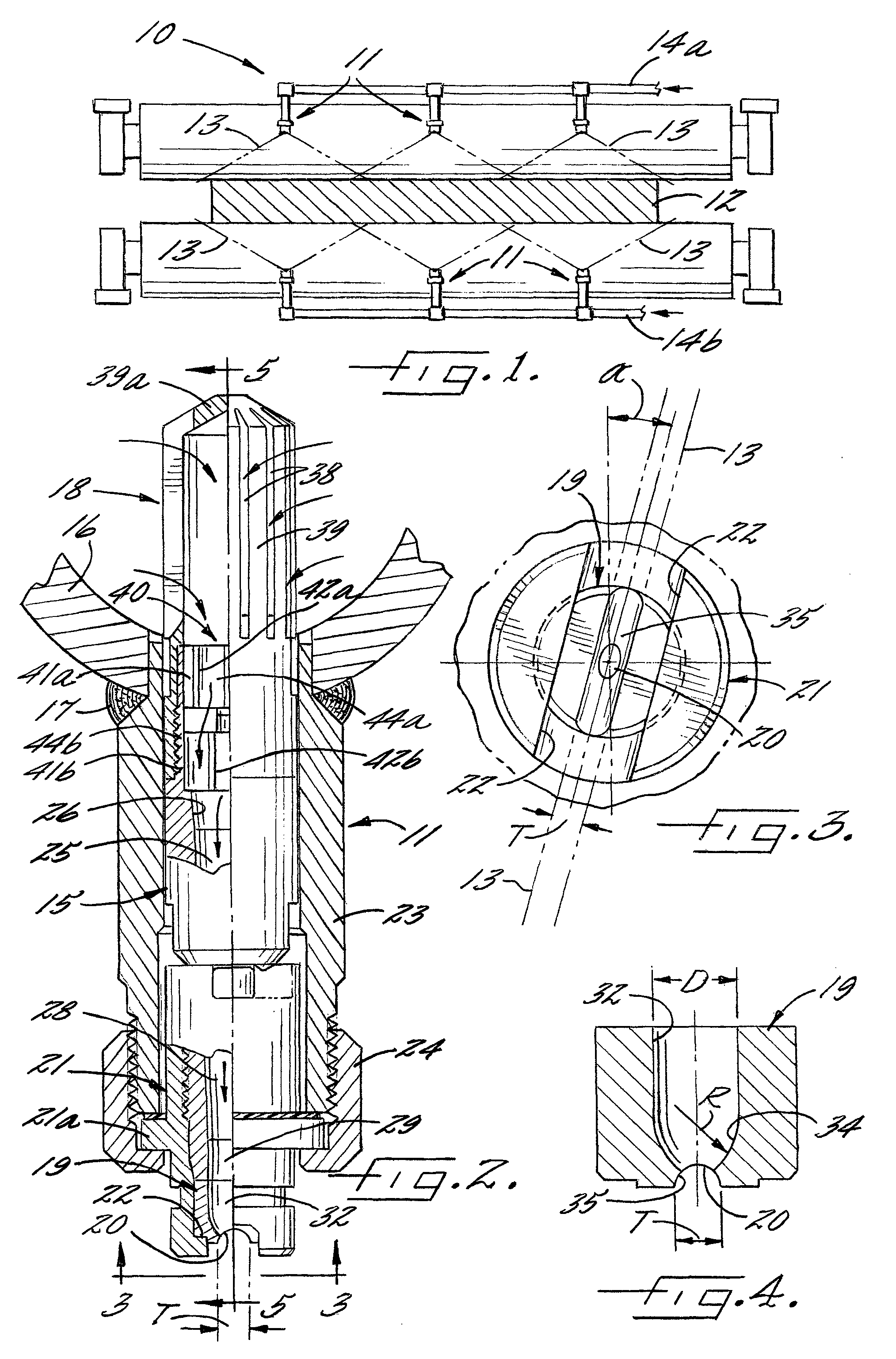

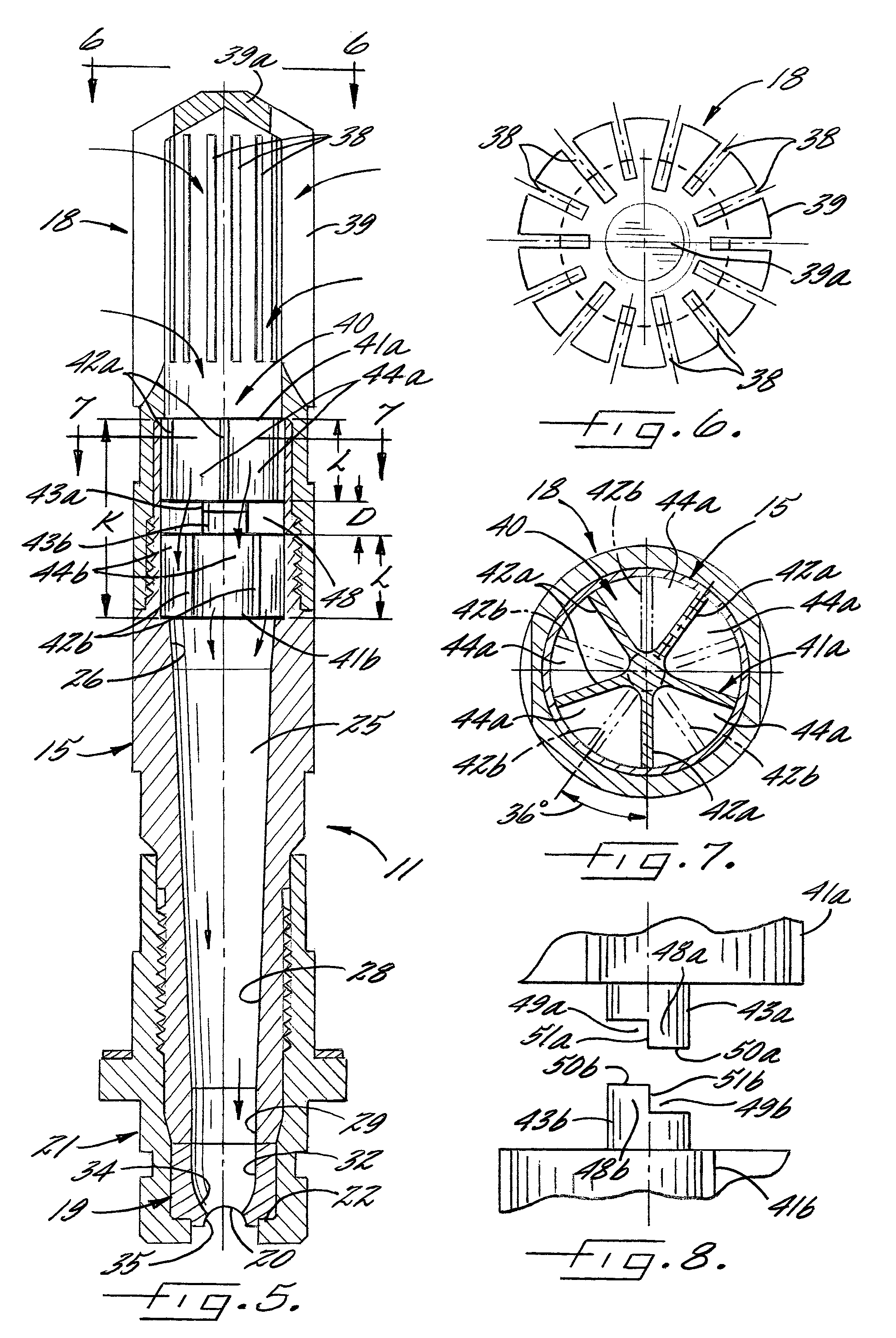

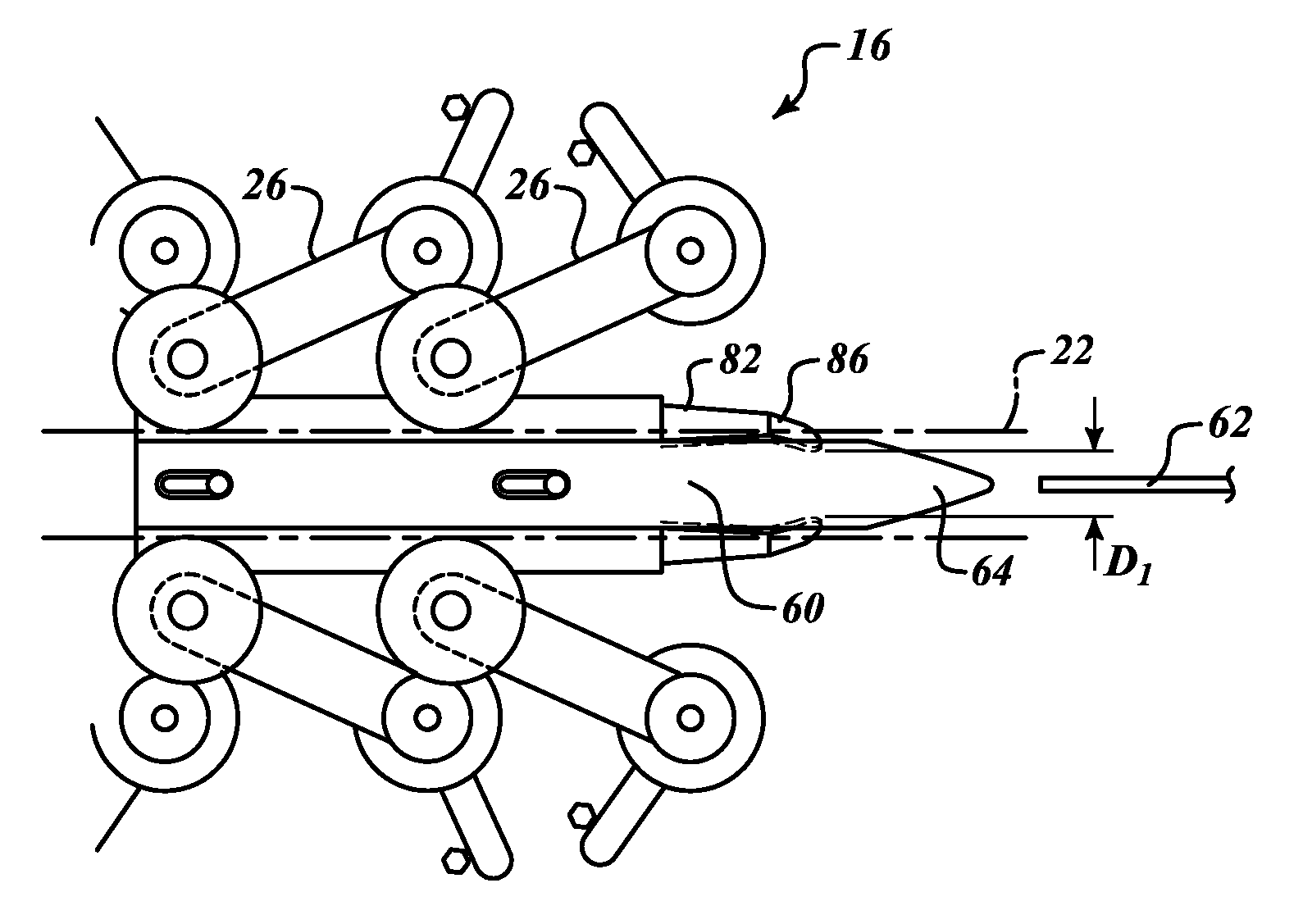

Descaling spray nozzle assembly

ActiveUS7913937B2Efficient and reliable removalEnhanced thin line high-pressure impactSpray nozzlesWork treatment devicesSpray nozzleEngineering

A spray nozzle assembly for directing thin, straight line, high pressure liquid spray onto moving steel slabs for penetrating and removing scale buildup in steel processing operations. The spray nozzle assembly includes a high impact attachment tube for accelerating liquid flow, a tungsten carbide spray tip at a discharge end of the high impact attachment tube for directing a flat spray pattern, an inlet defined by a strainer at an upstream end of the high impact attachment tube, and a staged vane section intermediate the inlet and spray tip for reducing liquid turbulence in the flow passageway. The vane section comprises a pair of axially spaced vanes each having a plurality of radial vane elements that define a plurality of laminar flow passageways, with the laminar flow passageways of one vane being circumferentially offset to the laminar flow passageways of the other vane.

Owner:SPRAYING SYST

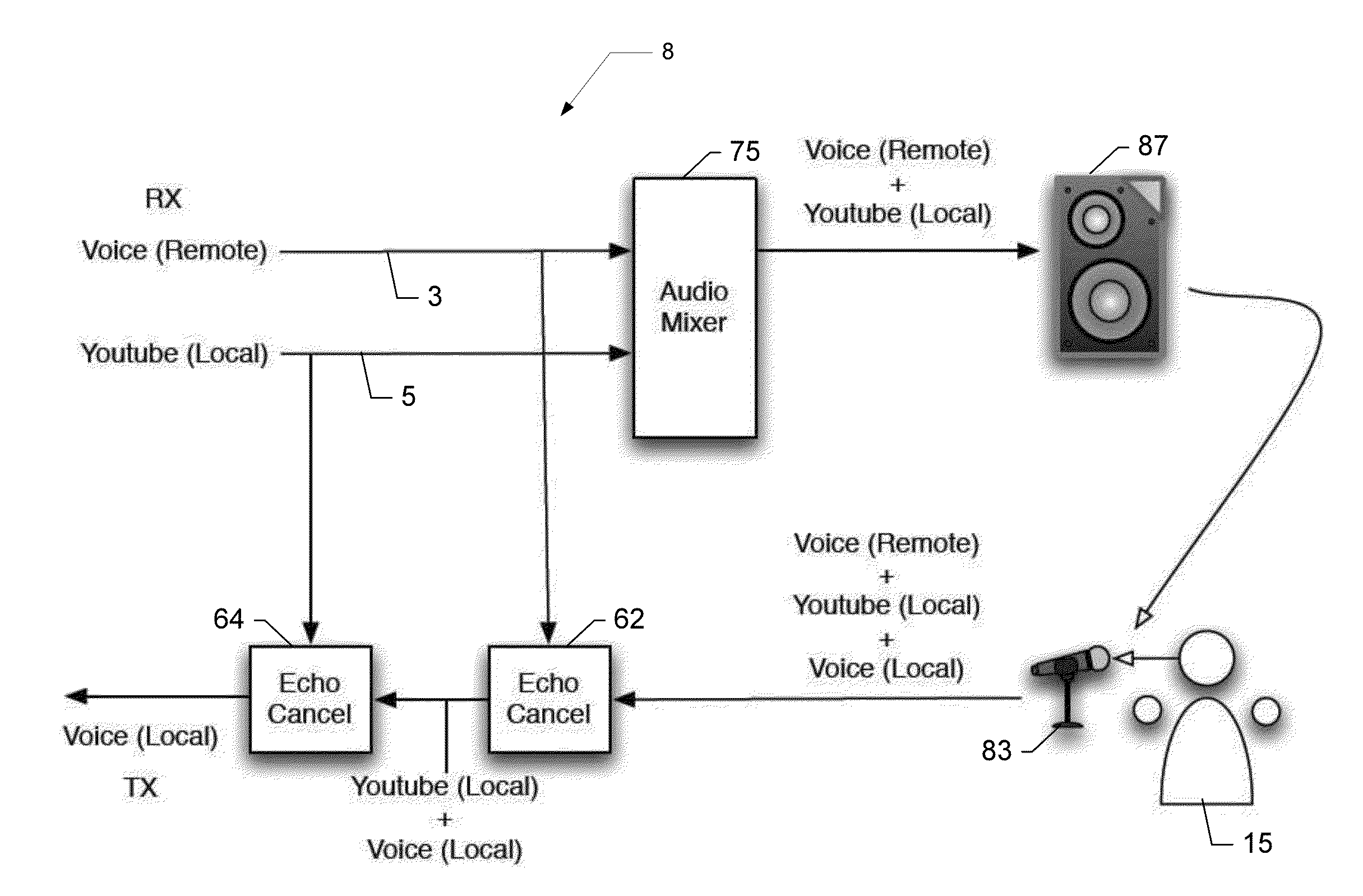

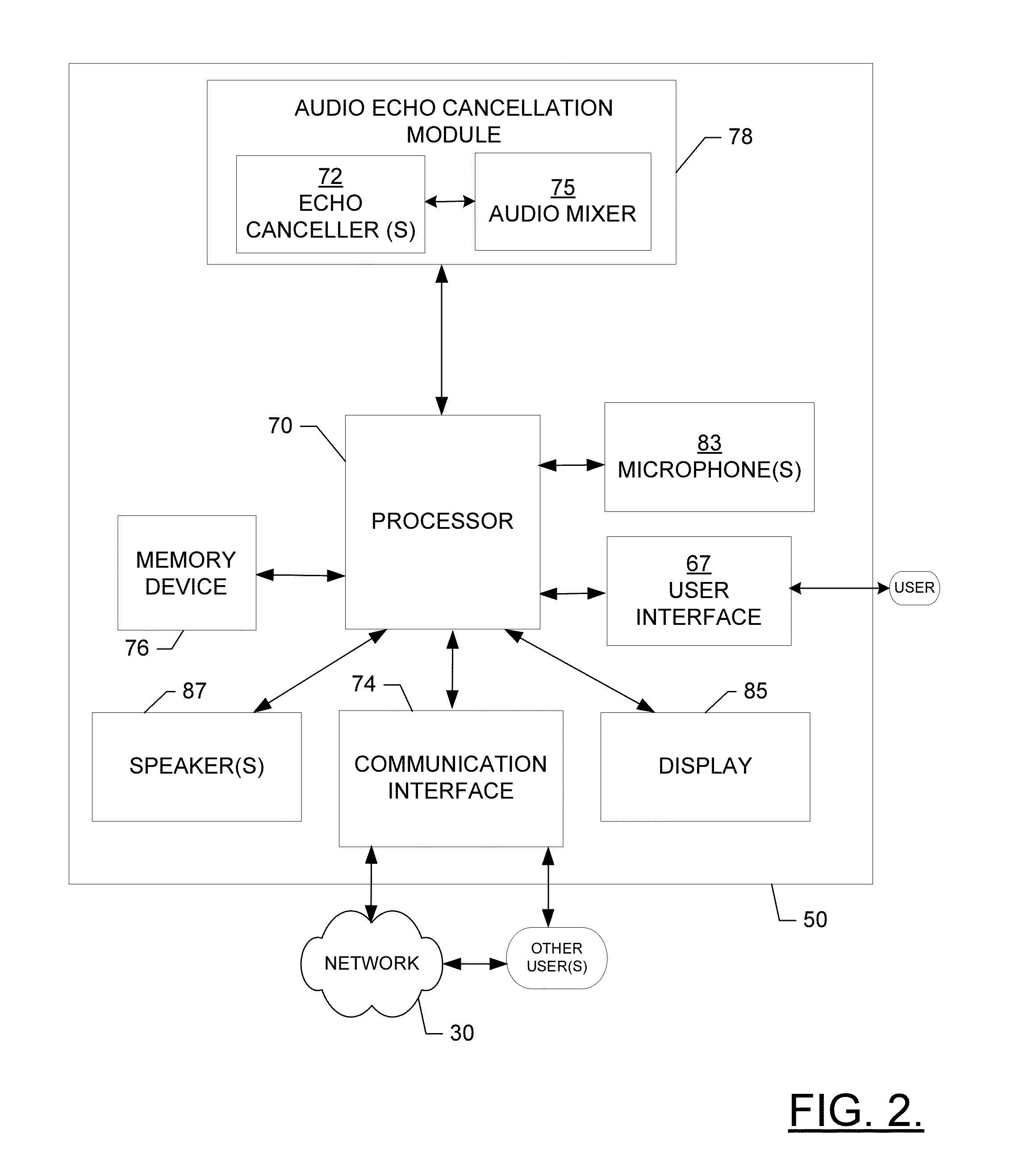

Methods, apparatuses and computer program products for providing active echo-cancellation for systems combining voice communication and synchronous audio content

ActiveUS20130003962A1Efficient and reliableEfficient and reliable removalTwo-way loud-speaking telephone systemsVoice communicationSpeech sound

An apparatus for removing an echo(es) from audio content may include a processor and memory storing executable computer code causing the apparatus to at least perform operations including receiving combined audio content including voice data associated with speech of users in a call and information including audio data provided to the users. The computer program code may further cause the apparatus to remove a first echo of a first item of voice data associated with a user(s), from the combined audio content, based in part on a prior detection of the first item of voice data. The computer program code may further cause the apparatus to remove a second echo of the audio data, from the combined audio content, based in part on a previous detection of the audio data or a previous detection of data corresponding to the audio data. Corresponding methods and computer program products are also provided.

Owner:NOKIA TECHNOLOGLES OY

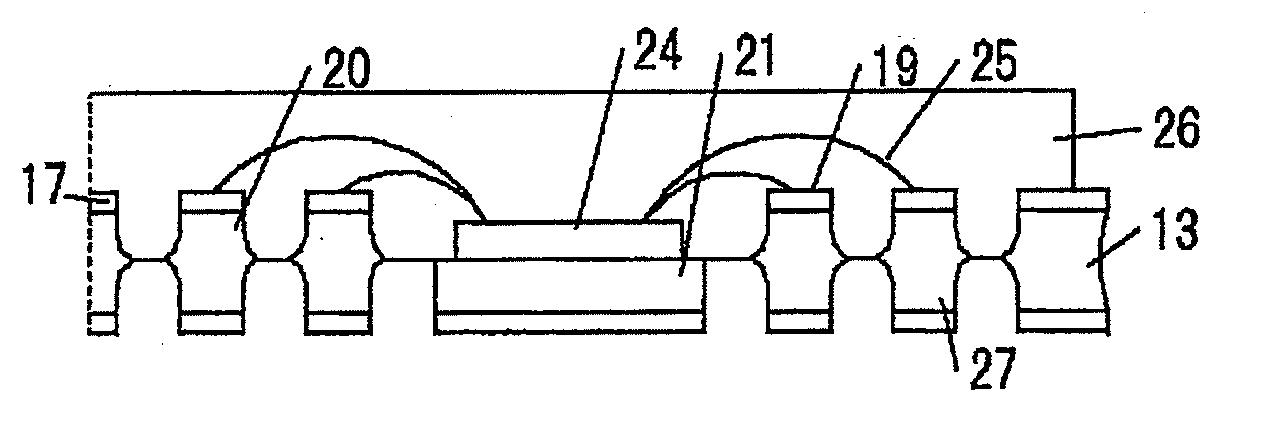

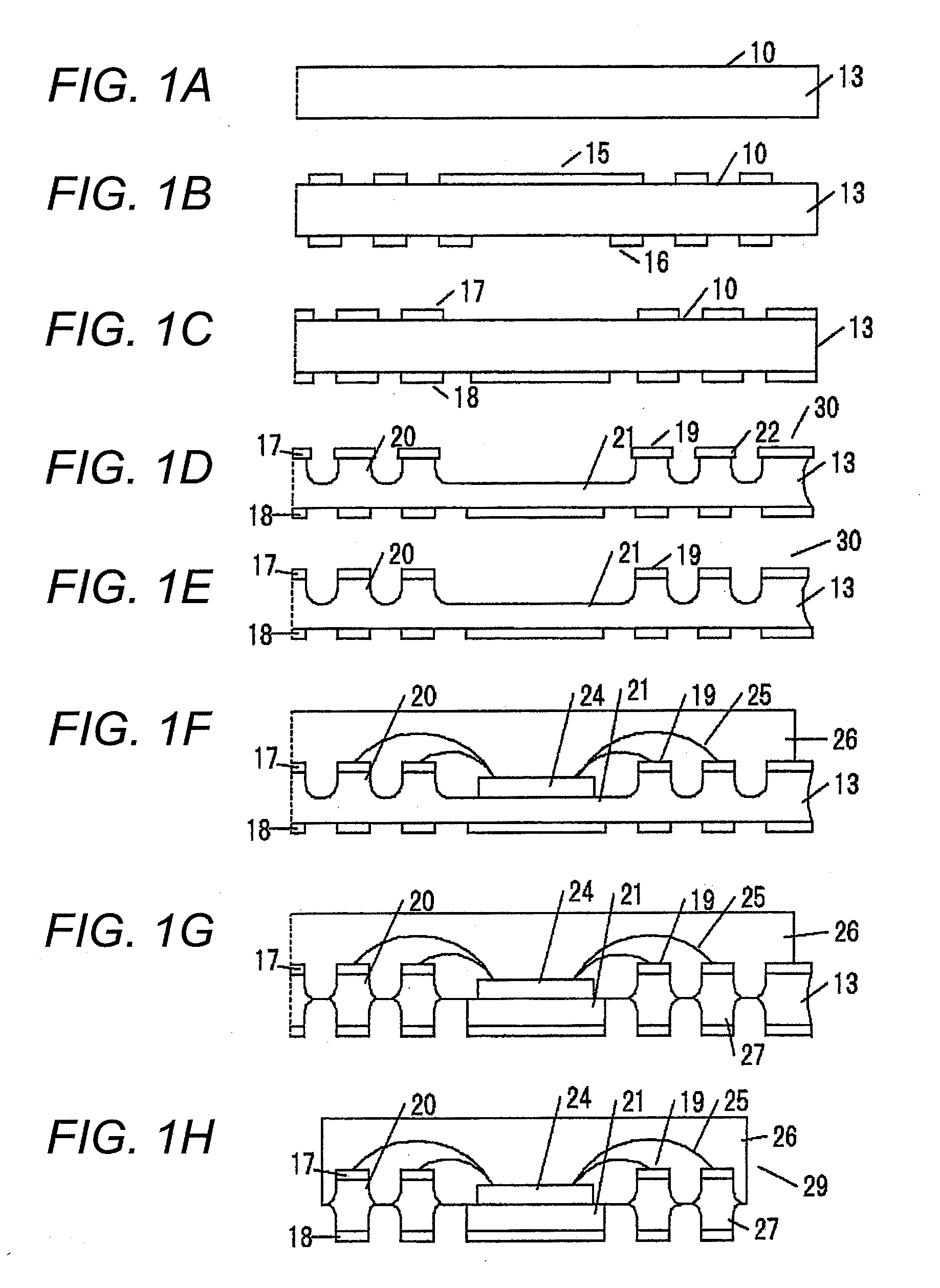

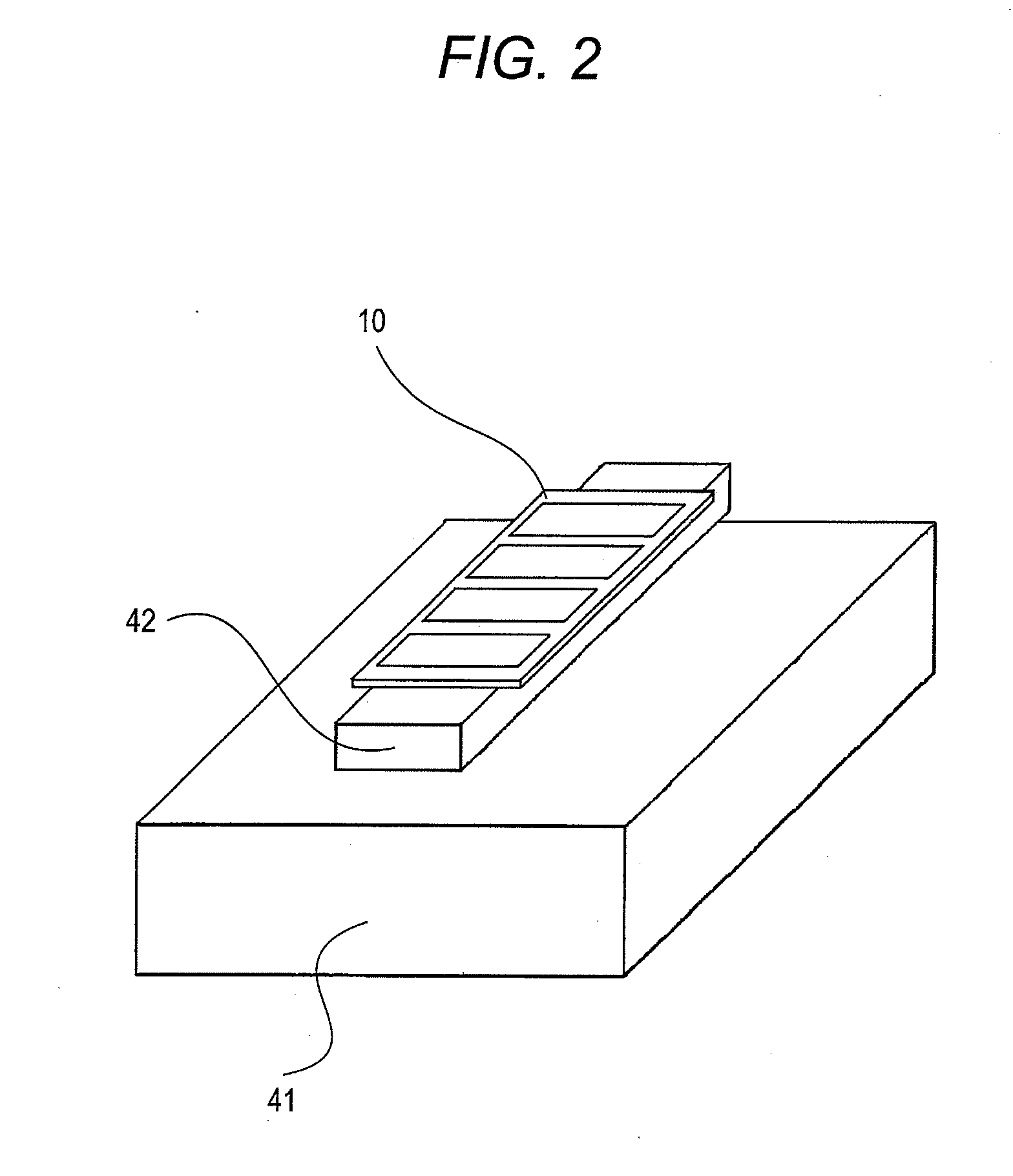

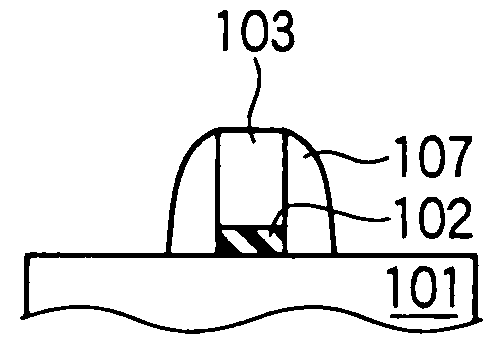

Manufacturing method of leadframe and semiconductor device

ActiveUS20110059577A1Avoid deformationEfficient and reliable removalSemiconductor/solid-state device detailsSolid-state devicesResistEtching

In order to remove plating burrs generated in etching step, there is provided a manufacturing method of semiconductor devices on each of unit leadframes in a leadframe material in which a plurality of the unit leadframes are arranged in plural rows or a single row, wherein at least two types of plating burr removals are conducted after a half-etching is performed onto a front surface side of the leadframe material, using a first plating layer as resist film.

Owner:ADVANCED SEMICON ENG INC

Removing method of tube

ActiveUS7297908B2Easily pull out and removeReduce the overall diameterDischarge tube luminescnet screensAssembly machinesEngineering

The present invention provides a removing method of a tube. Upon removing a tube 3 increased in diameter and fixed to a tube-sheet 1, an inserted portion 3a which is fixed to a tube-hole 2 of the tube-sheet 1 is heated and then cooled, thereby reducing its diameter. The inserted portion 3a is loosened from the tube-hole 2. Then, a region 3h opposed to a groove 4 formed in an inner circumference of the tube-hole is heated to a red-hot state, and the tube 3 is stretched in its axial direction, the red-heated region 3h is stretched to reduce its diameter and cut the region 3h, thereby pulling out the tube 3 from the tube-sheet 1.

Owner:DAI ICHI HIGH FREQUENCY

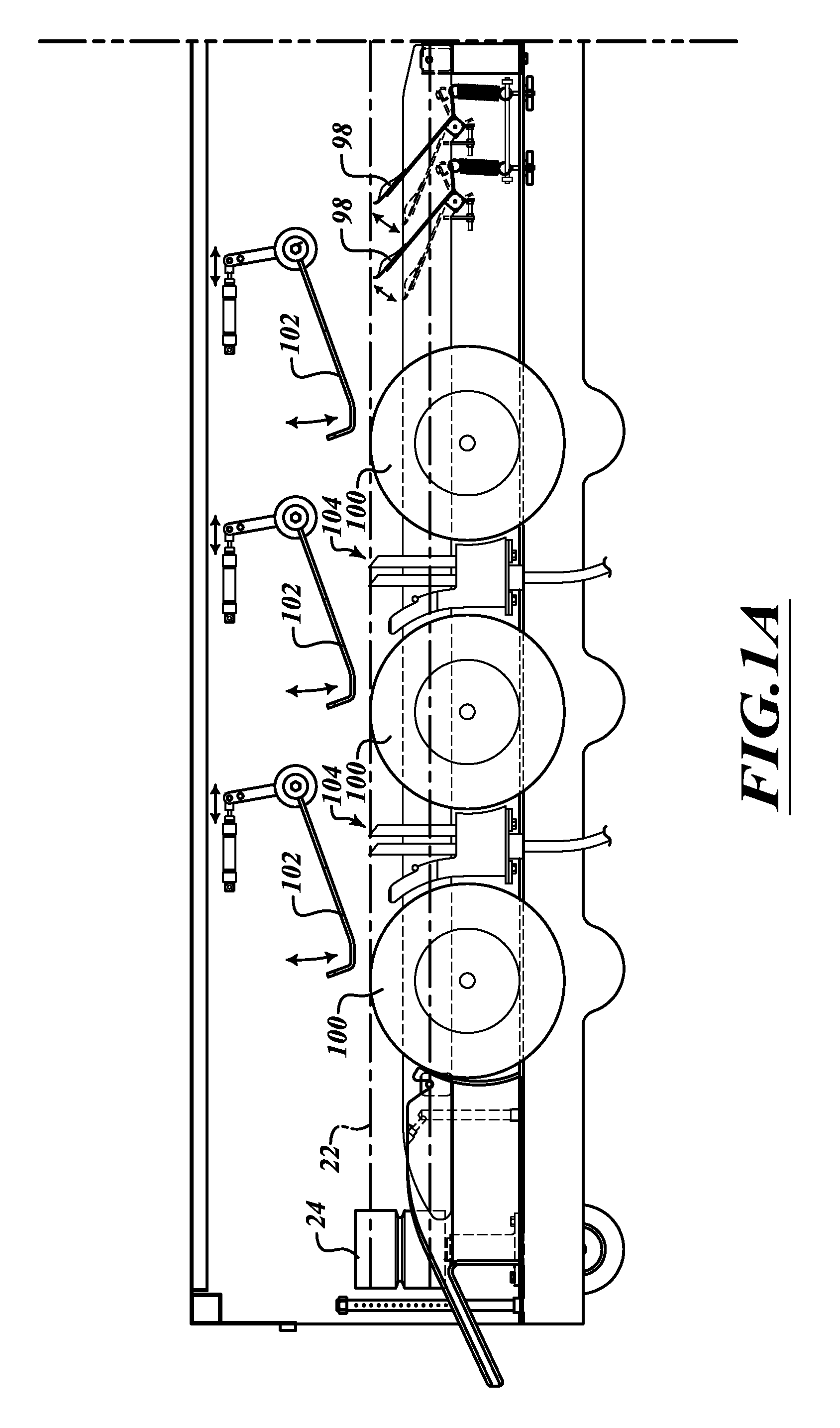

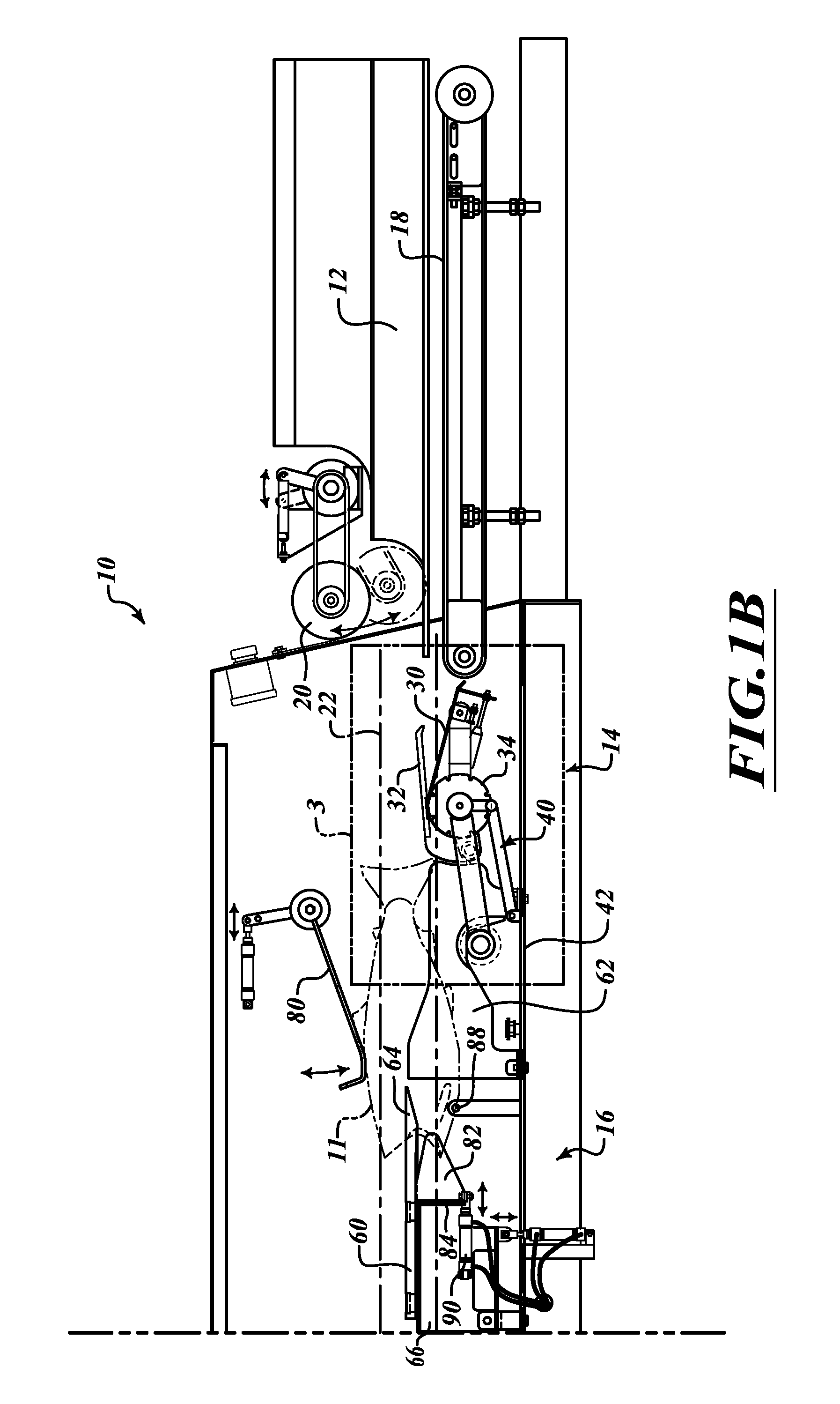

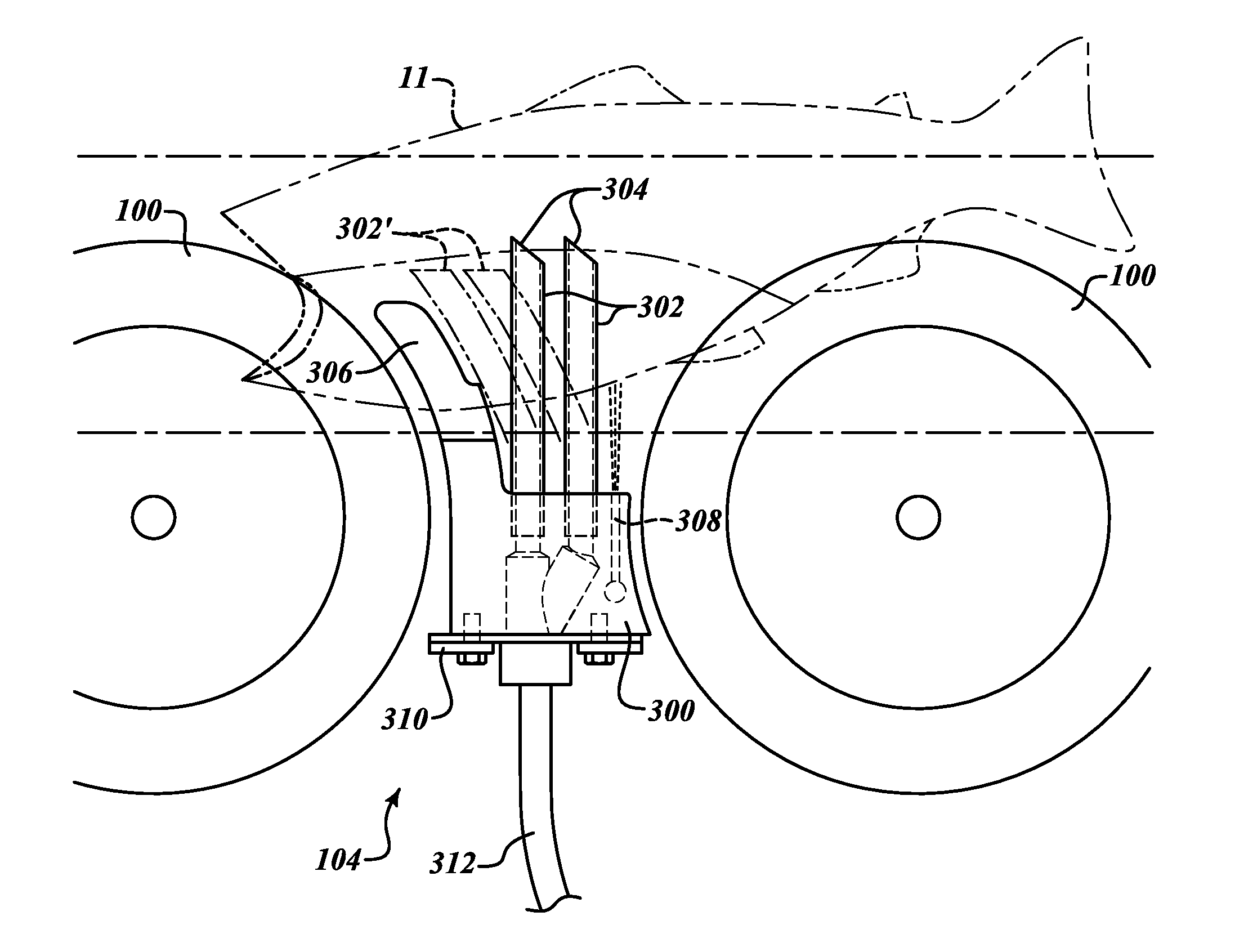

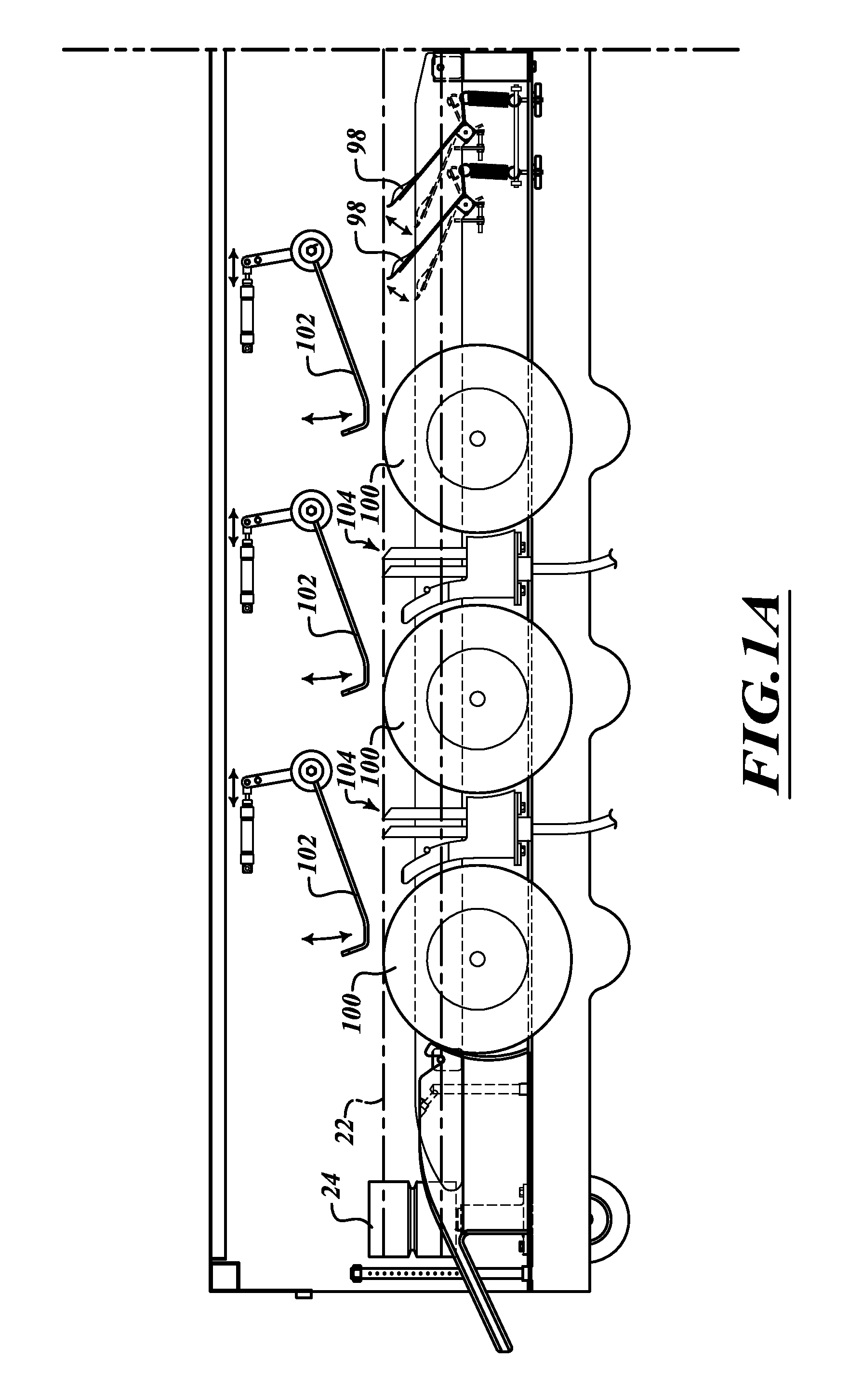

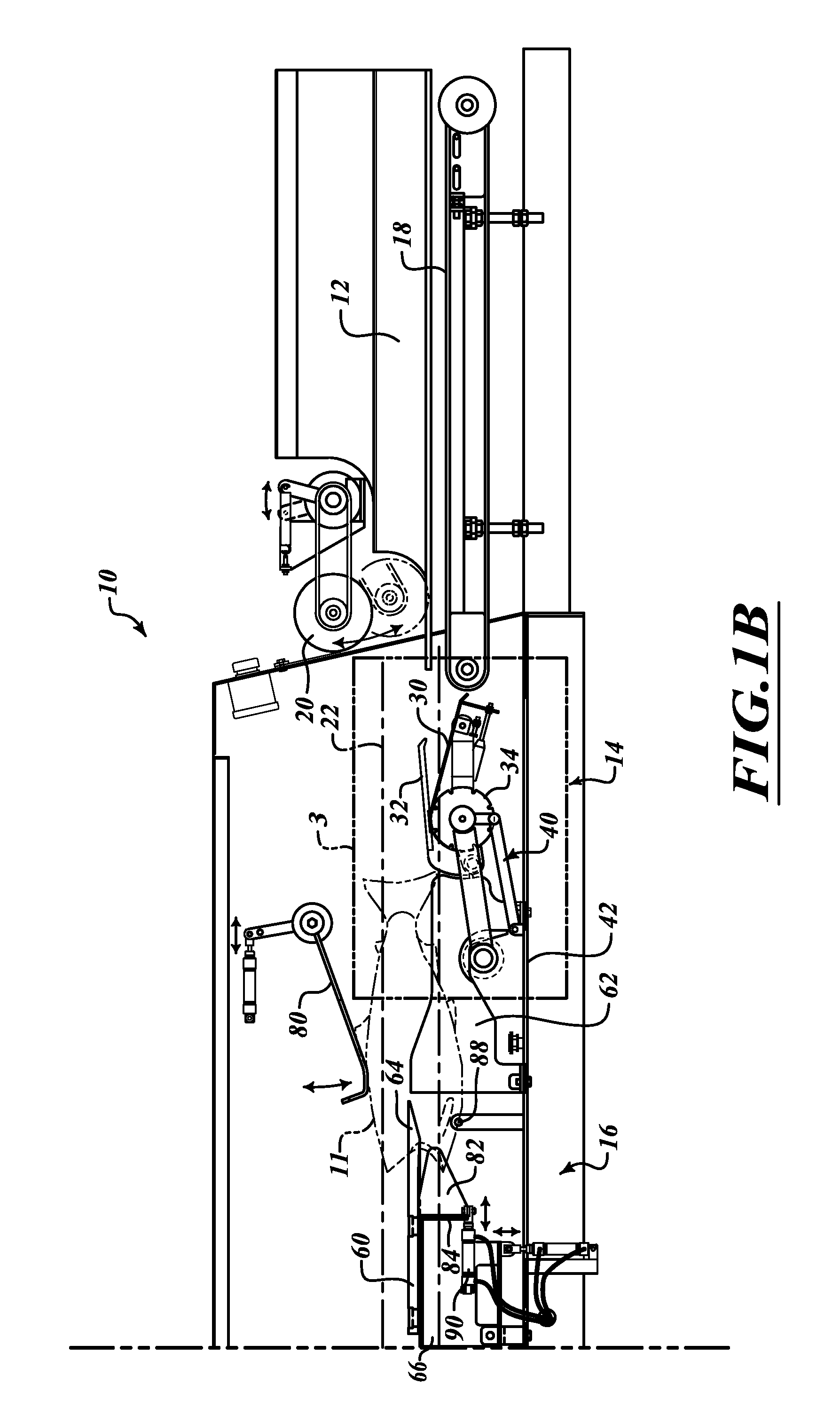

Fish processing system and method

ActiveUS20130040544A1Efficient and reliable removalEasy to cleanPoultry eviscerating devicesSausage casingsSting fishEngineering

Methods and systems for processing fish are provided which enable cutting of the fish and removal of the viscera without damage to either the viscera or the remaining fish product. The systems may include an adjustable cutting device to cut the belly in a particularly unobtrusive manner and / or an adjustable gutting device to severe a gullet of the fish from the fish body and to gather and remove the viscera without significant damage to the viscera or the remaining fish product. Extractors for severing the connection between the gullet and the fish are also provided to assist in removal of the viscera, including the gonads. Vacuum head assemblies for cleaning a cavity of the fish after the viscera is removed are also provided.

Owner:RYCO EQUIP

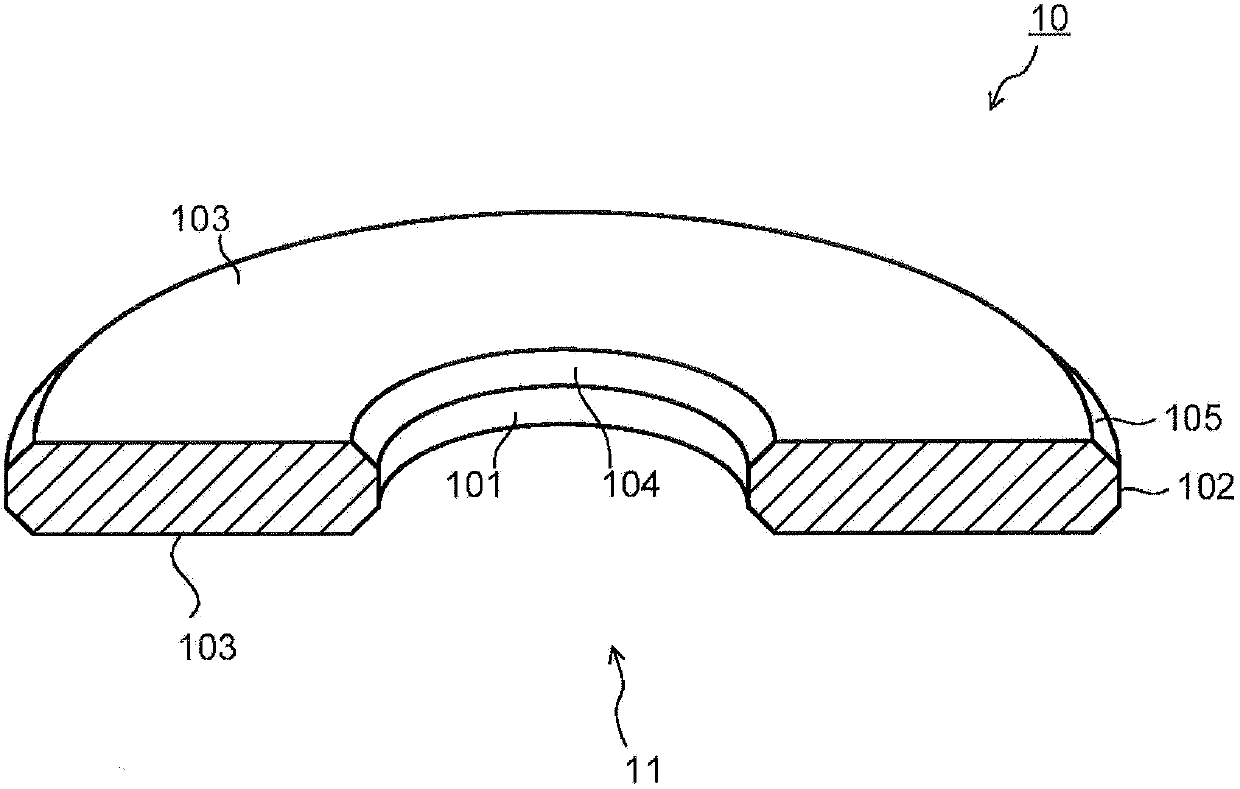

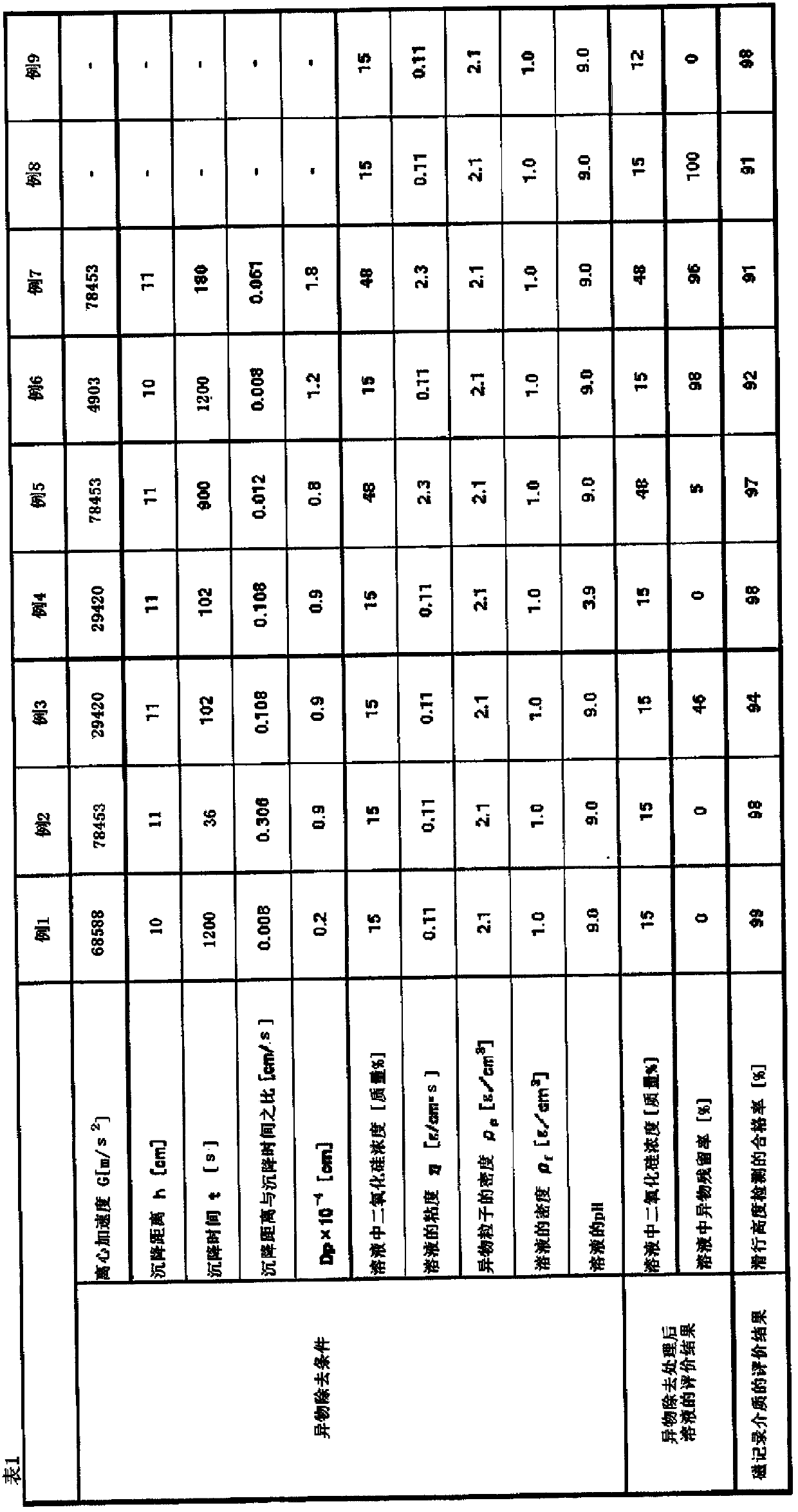

Silicon dioxide solution preparation method, grinding fluid, and manufacture method of glass substrate

InactiveCN103396763AEfficient and reliable removalAvoid damageOther chemical processesRecord carriers manufactureForeign matterSilicon dioxide

The invention provides a silicon dioxide solution preparation method, grinding fluid, and a manufacture method of a glass substrate. The silicon dioxide solution preparation method is a silicon dioxide solution preparation method for removing foreign matters from a silicon dioxide solution containing silicon dioxide particles with a primary particle size of 1-80 nm, wherein the centrifugal acceleration G, the ratio of the sediment distance and the sediment time h / t, and the viscosity [eta] of the solution are controlled, thereby enabling the particle size Dp of the removed foreign matters to be 0.1-1 [mu]m. The grinding fluid is used in grinding of a main plane of the glass substrate for a magnetic recording medium, and contains the silicon dioxide solution prepared by the silicon dioxide solution preparation method enabling the particle size Dp of the removed foreign matters to be 0.1-1 [mu]m. The manufacture method of the glass substrate for the magnetic recording medium includes a procedure of using the grinding fluid to grind the main plane.

Owner:ASAHI GLASS CO LTD

Image forming apparatus having charging unit with separate intake and exhaust ducts

ActiveUS7415218B2Efficient and reliable removalElectrographic process apparatusLatent imageImage formation

In an image forming apparatus that uses a charging unit to charge a photosensitive drum, forms an electrostatic latent image by carrying out image exposure according to image information, and transfers to a paper the electrostatic latent image by developing the electrostatic latent image into a visible image using a developer so that the image information is presented, an exhaust duct 33 for exhausting air that contains ozone produced within a drum unit 30, which includes a photosensitive drum 3 and a charging unit 5, and a duct 32 for taking in air, which draws in fresh air, are provided within the drum unit 30 so that ventilation of the drum unit 30 can be carried out with excellent efficiency.

Owner:SHARP KK

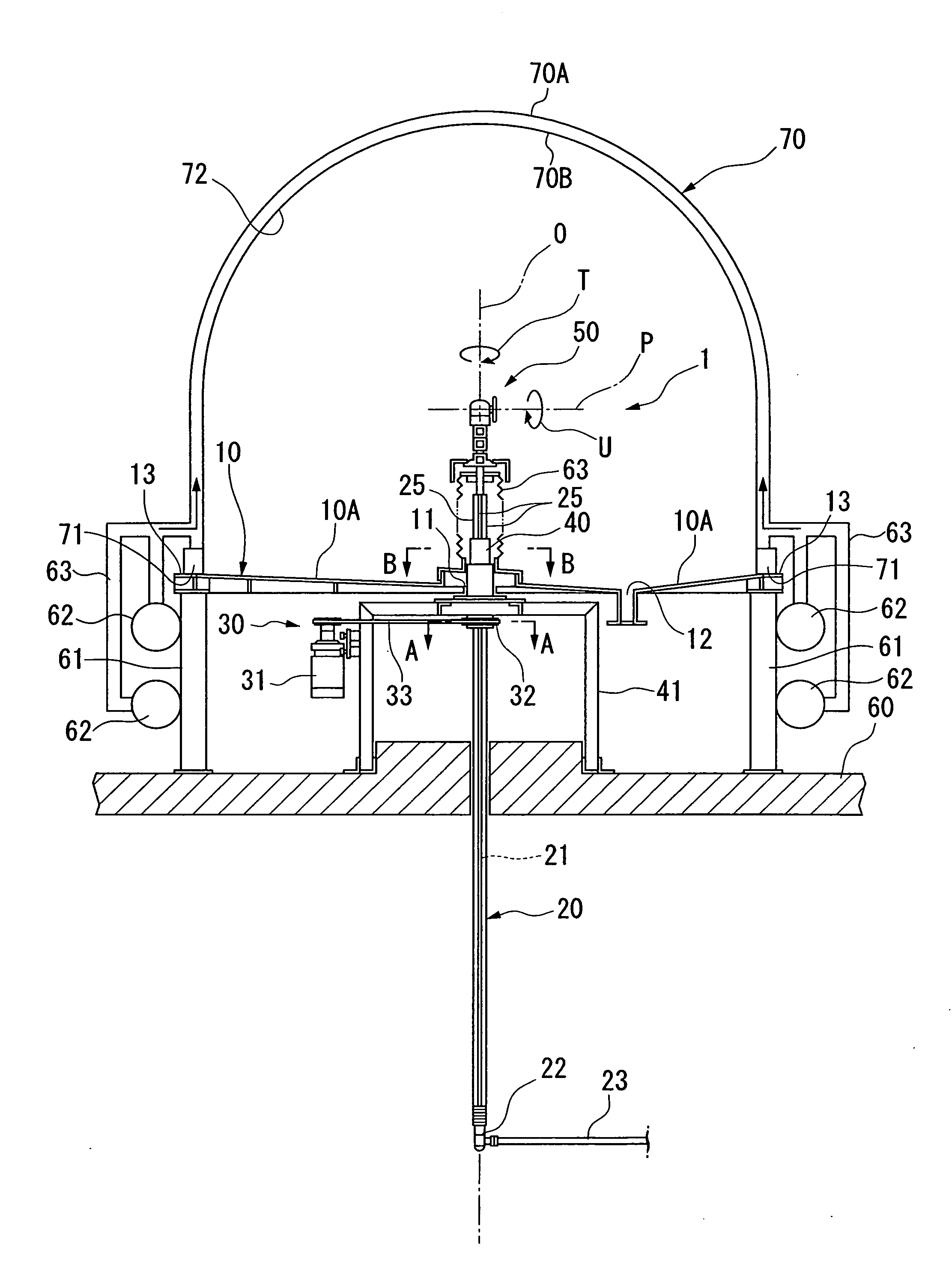

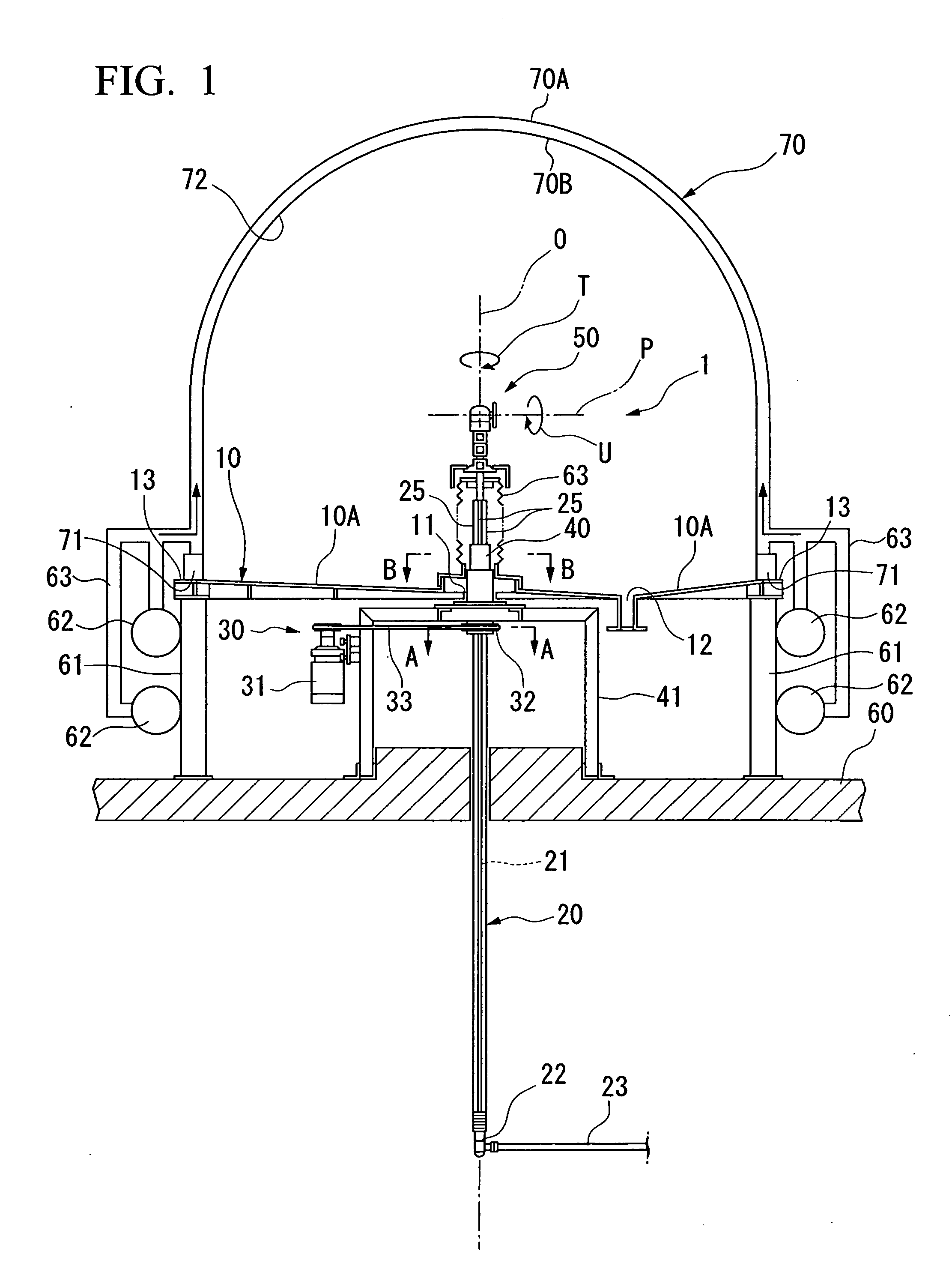

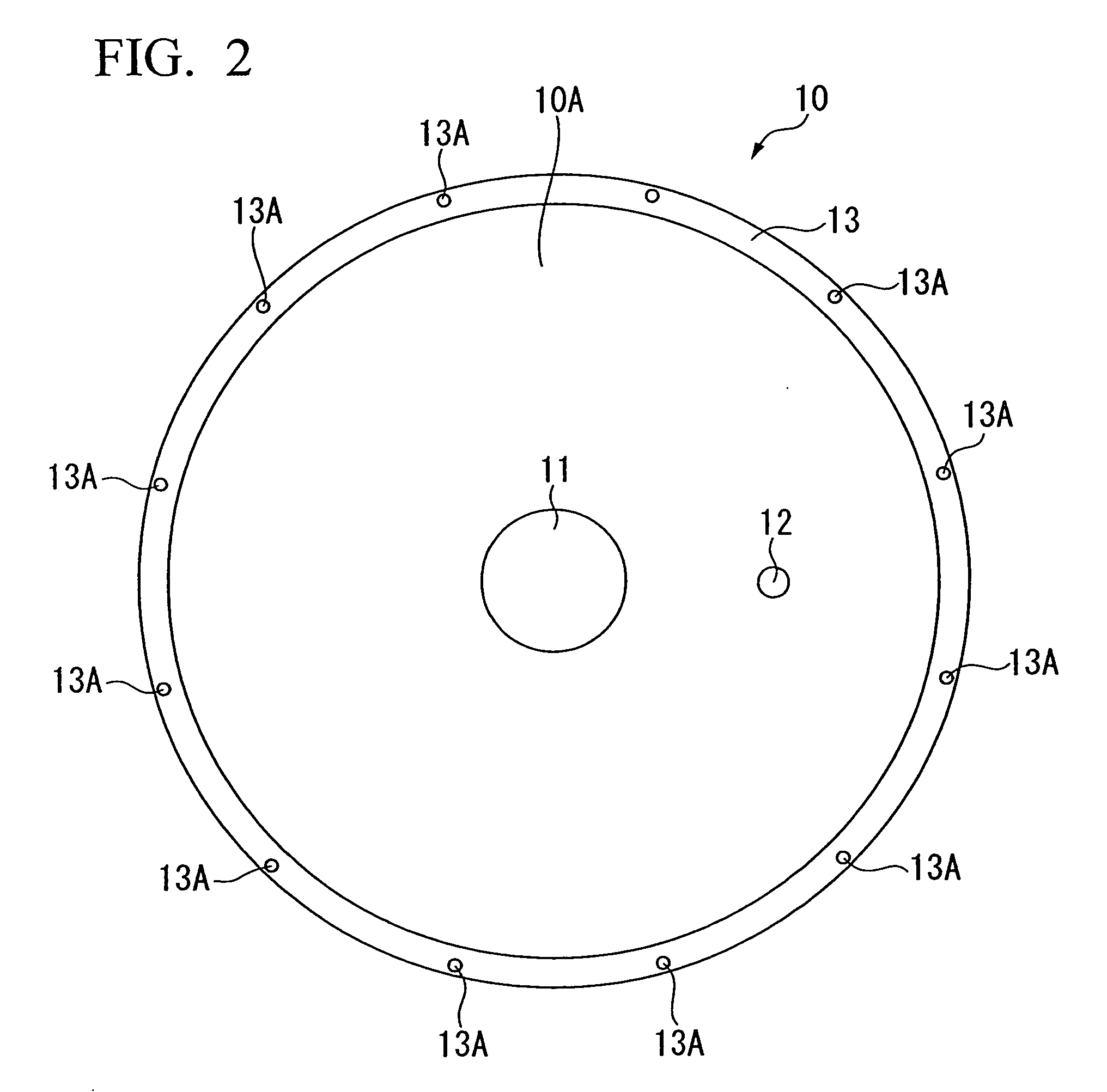

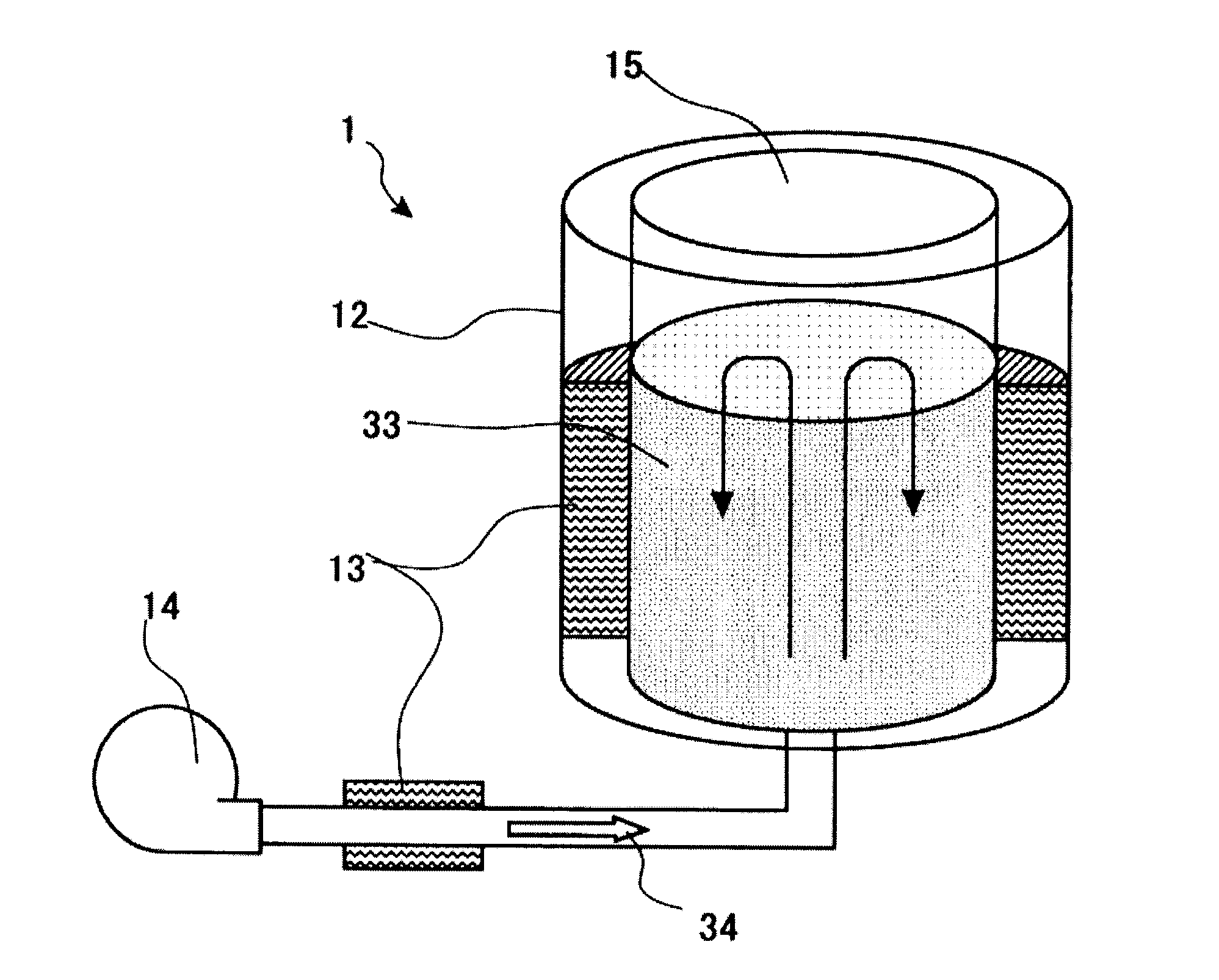

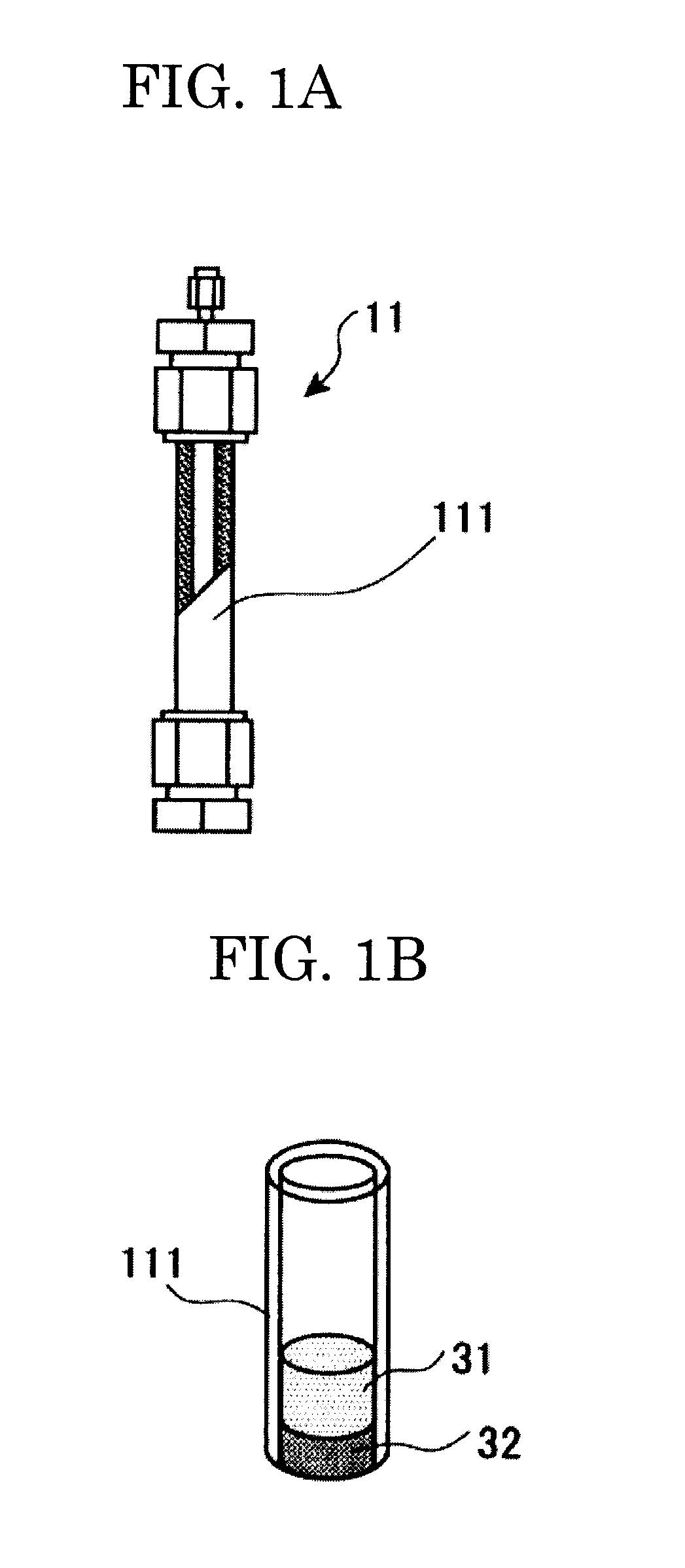

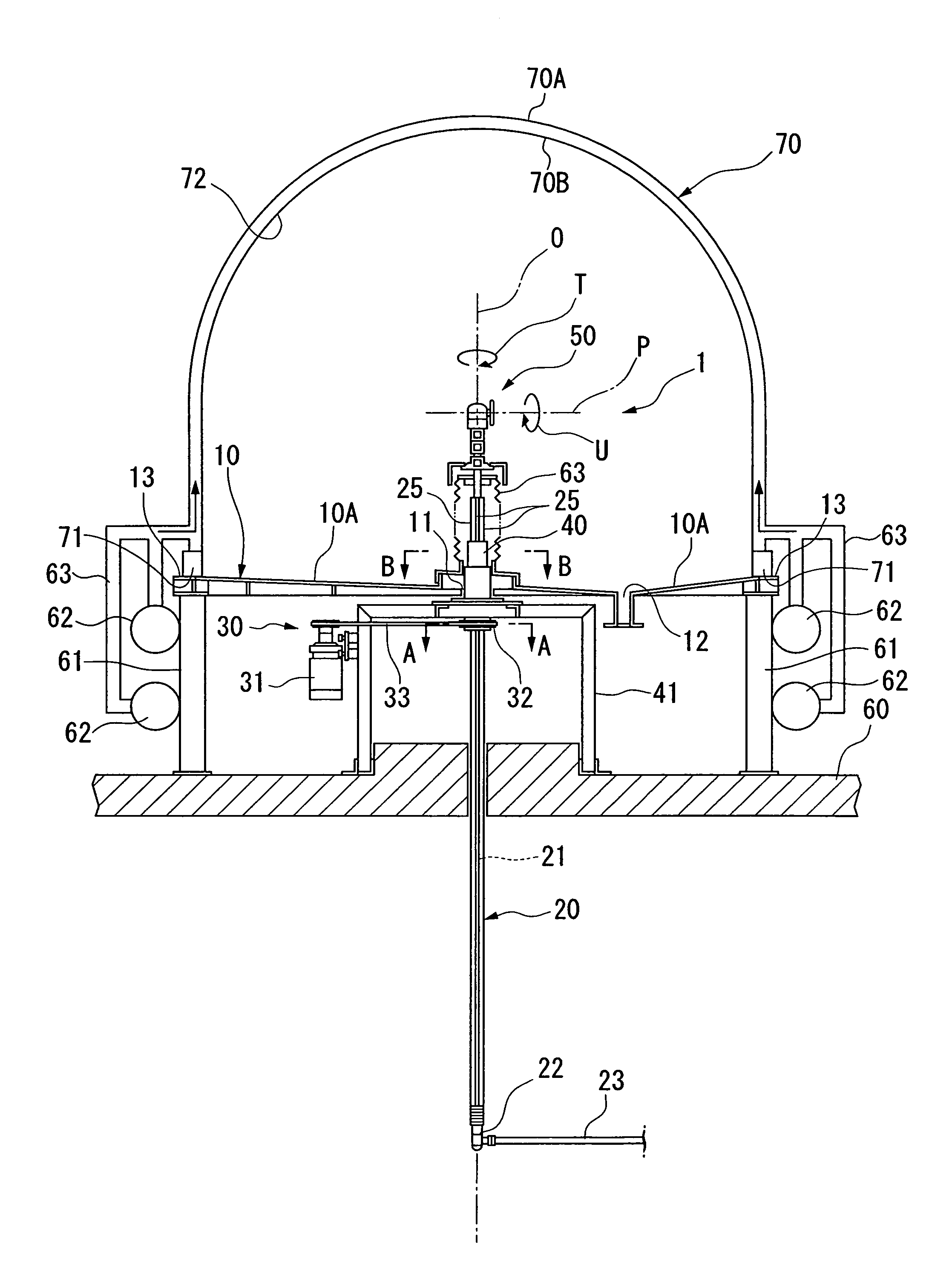

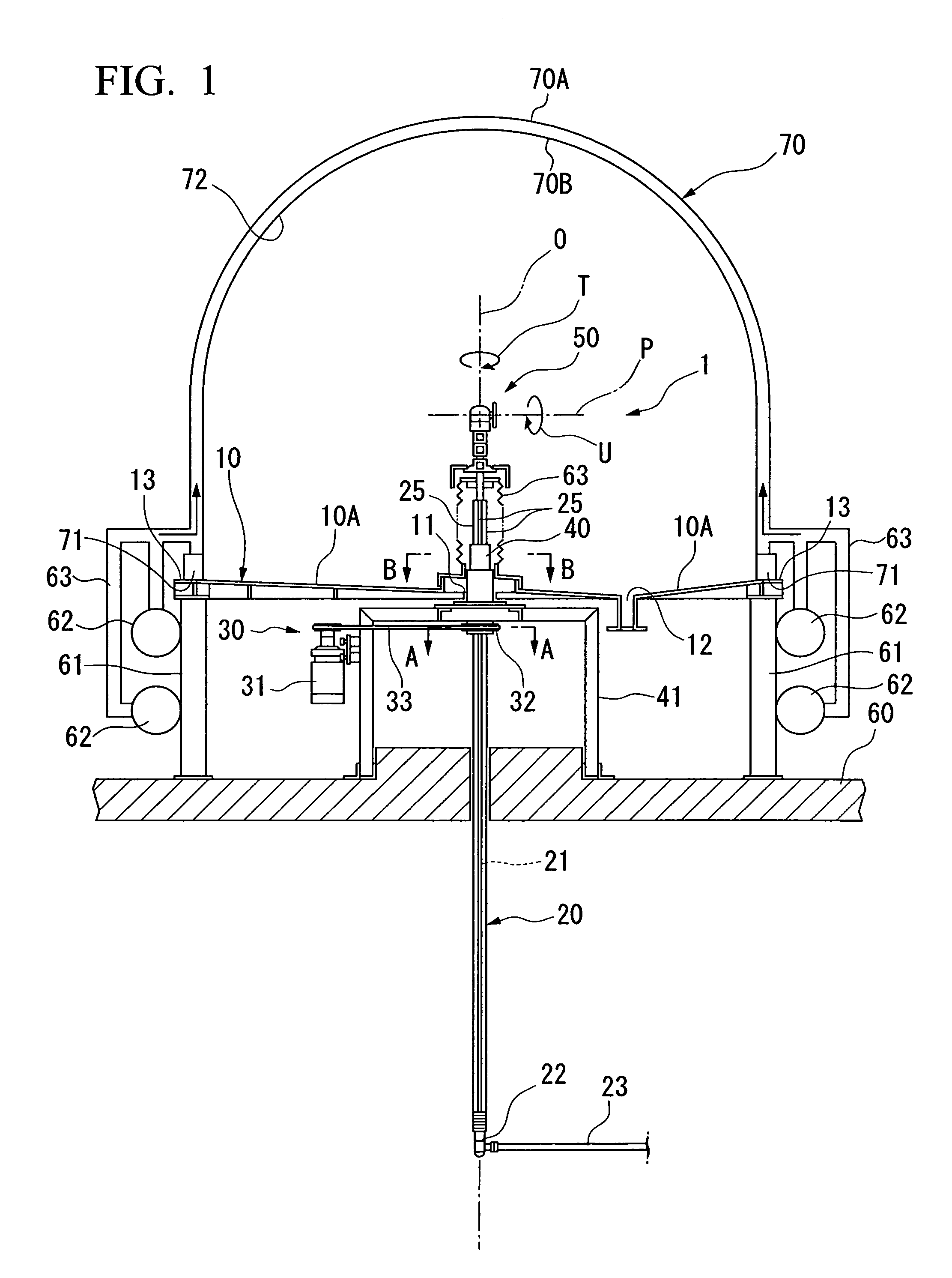

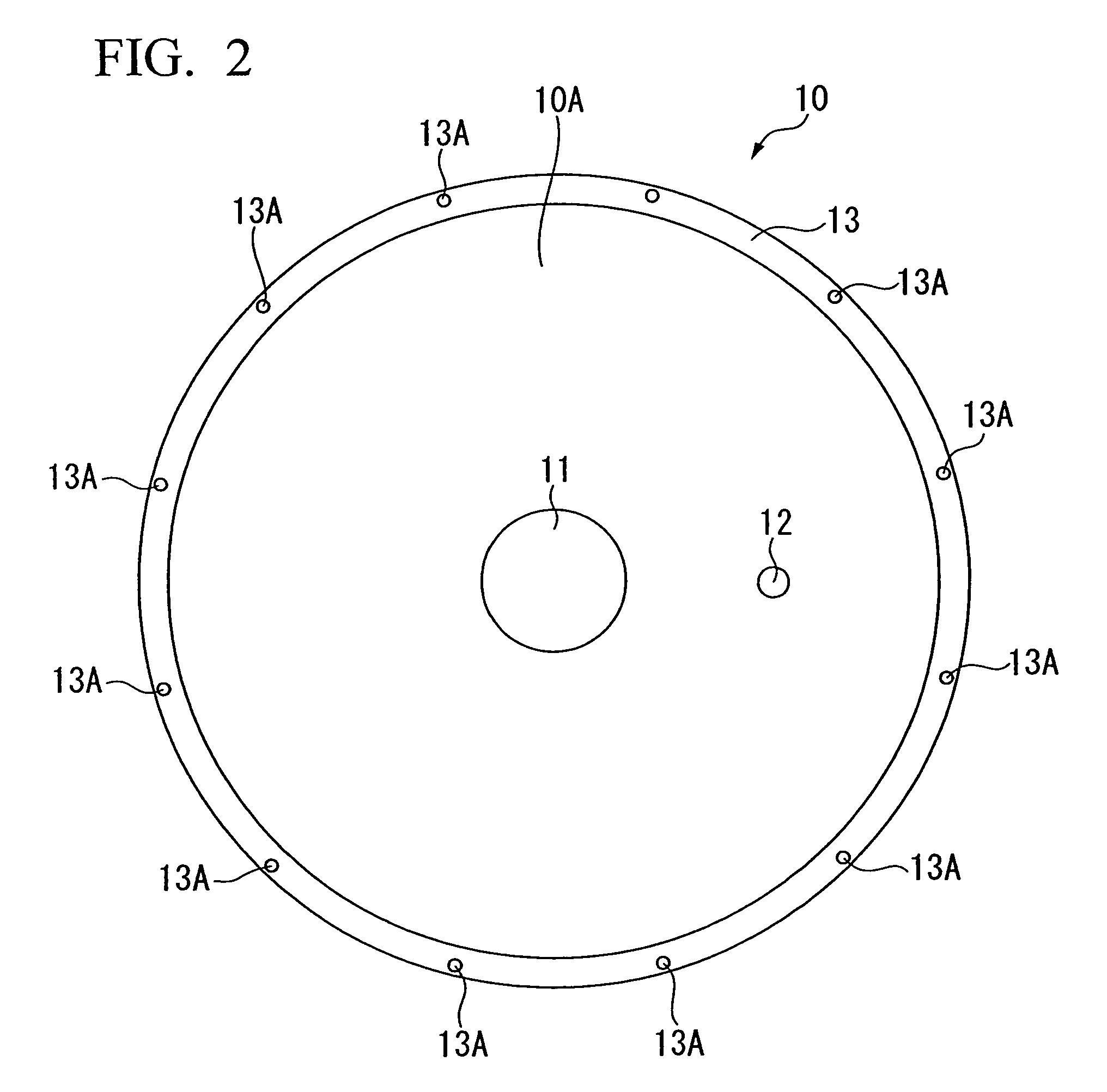

Reactor cleaning apparatus

ActiveUS20090188532A1Efficient and reliable removalSpray evenlyLiquid surface applicatorsSiliconNuclear engineeringHigh pressure

In a reactor cleaning apparatus 1 which cleans an inner wall surface 72 of a reactor 70 which generates polycrystalline silicon, a bell jar of the reactor 70 has a dual structure, a through hole 11 is formed along a vertical direction at a central portion of a substantially disc-like tray 10 placed in a horizontal state, a flange portion 13 in which an opening edge of the reactor 70 is placed is formed at an outer peripheral portion of the tray 10, a shaft 20 is provided through the through hole 11 of the tray 10 so as to be rotatable and movable in the vertical direction, a nozzle device 50 which sprays a cleaning water at high pressure in three-dimensional directions is provided at an upper end of the shaft 20, a drive mechanism 30 which rotates the shaft 20 and moves the shaft in the vertical direction is provided at a base end of the shaft 20, and steam piping 62 capable of supplying the steam within the bell jar of the reactor 70 is provided.

Owner:HIGH-PURITY SILICON CORP

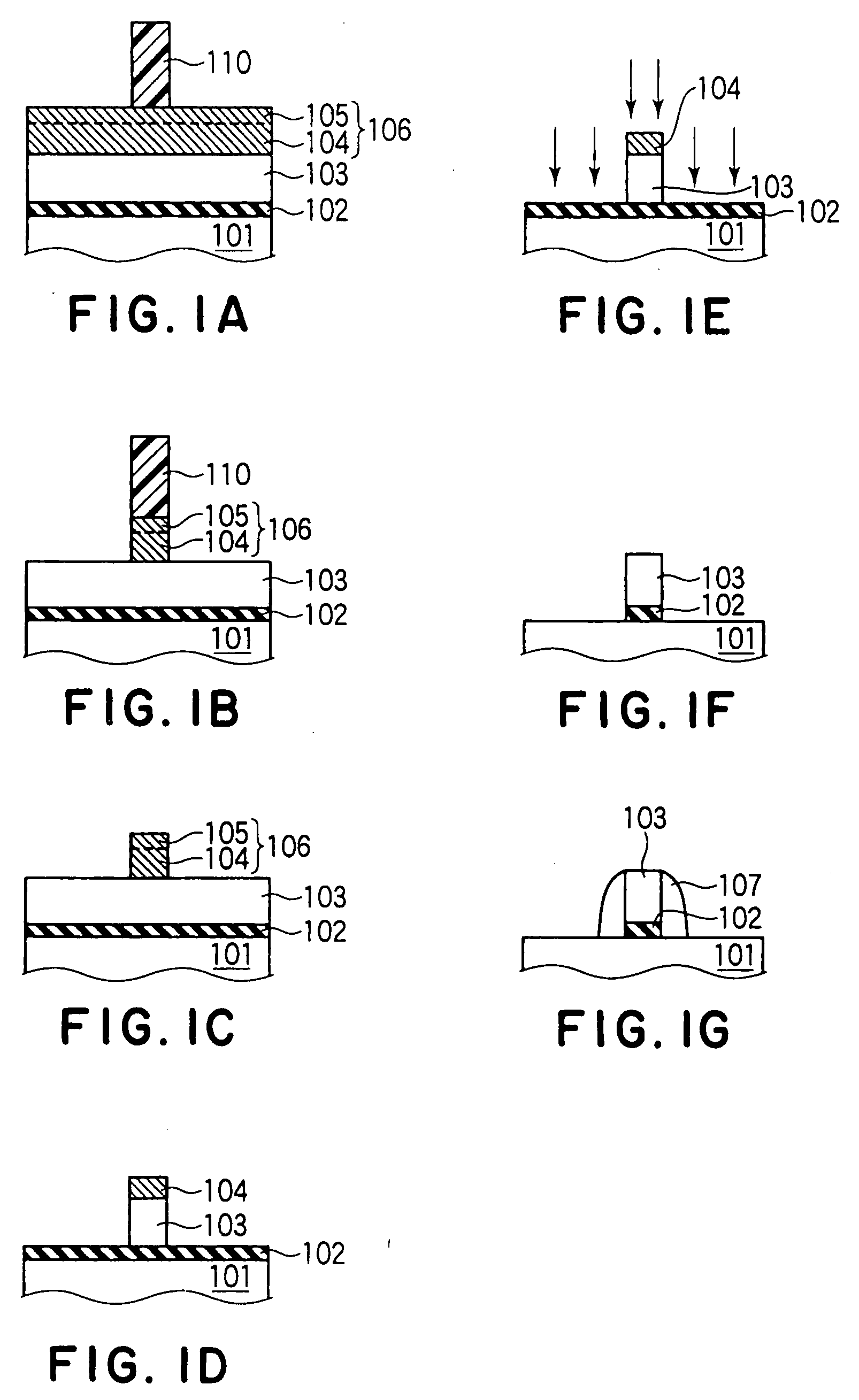

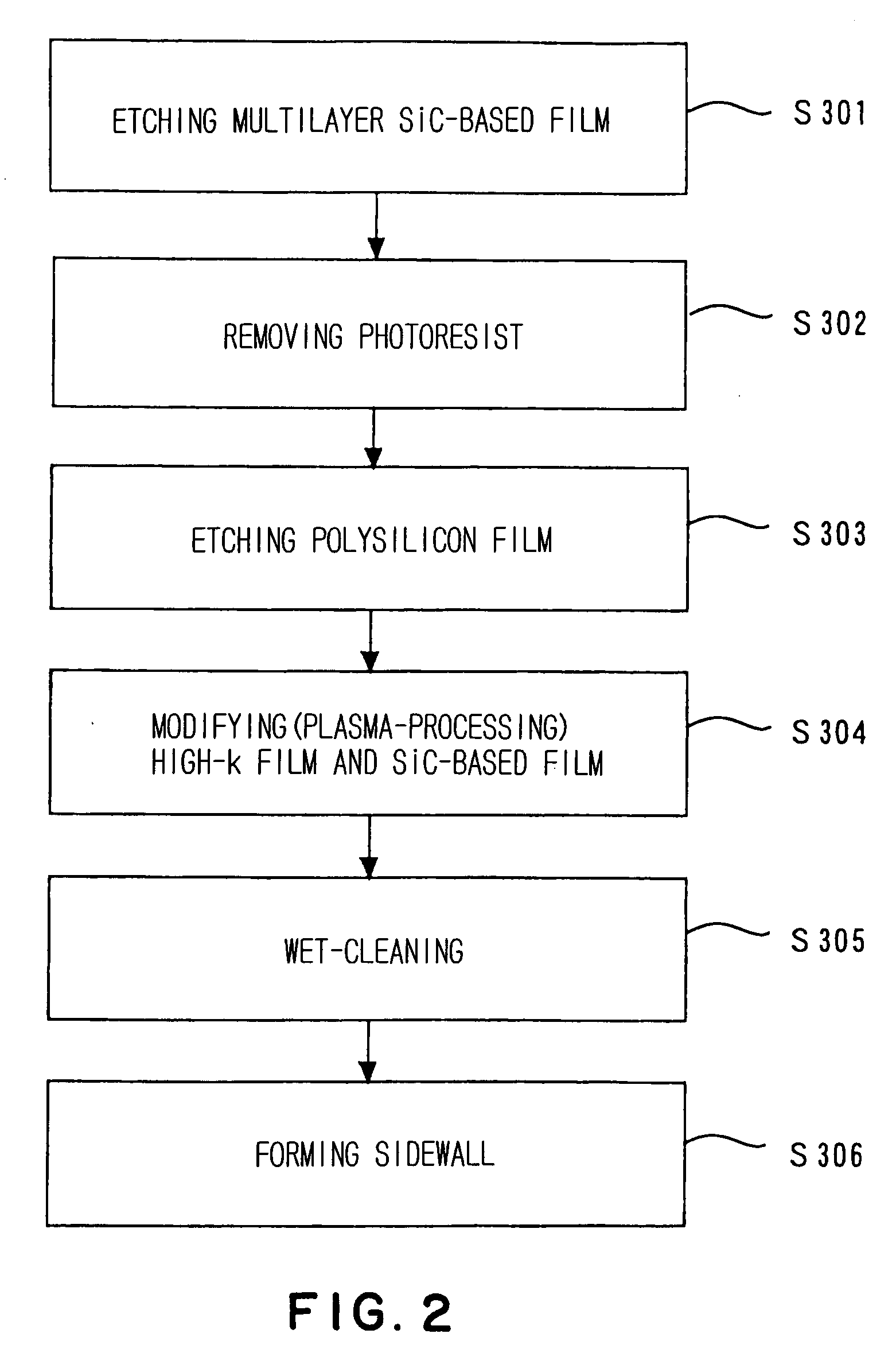

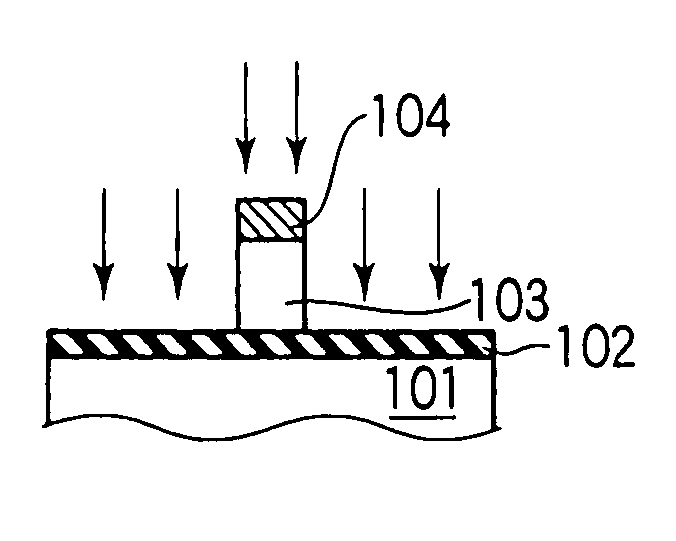

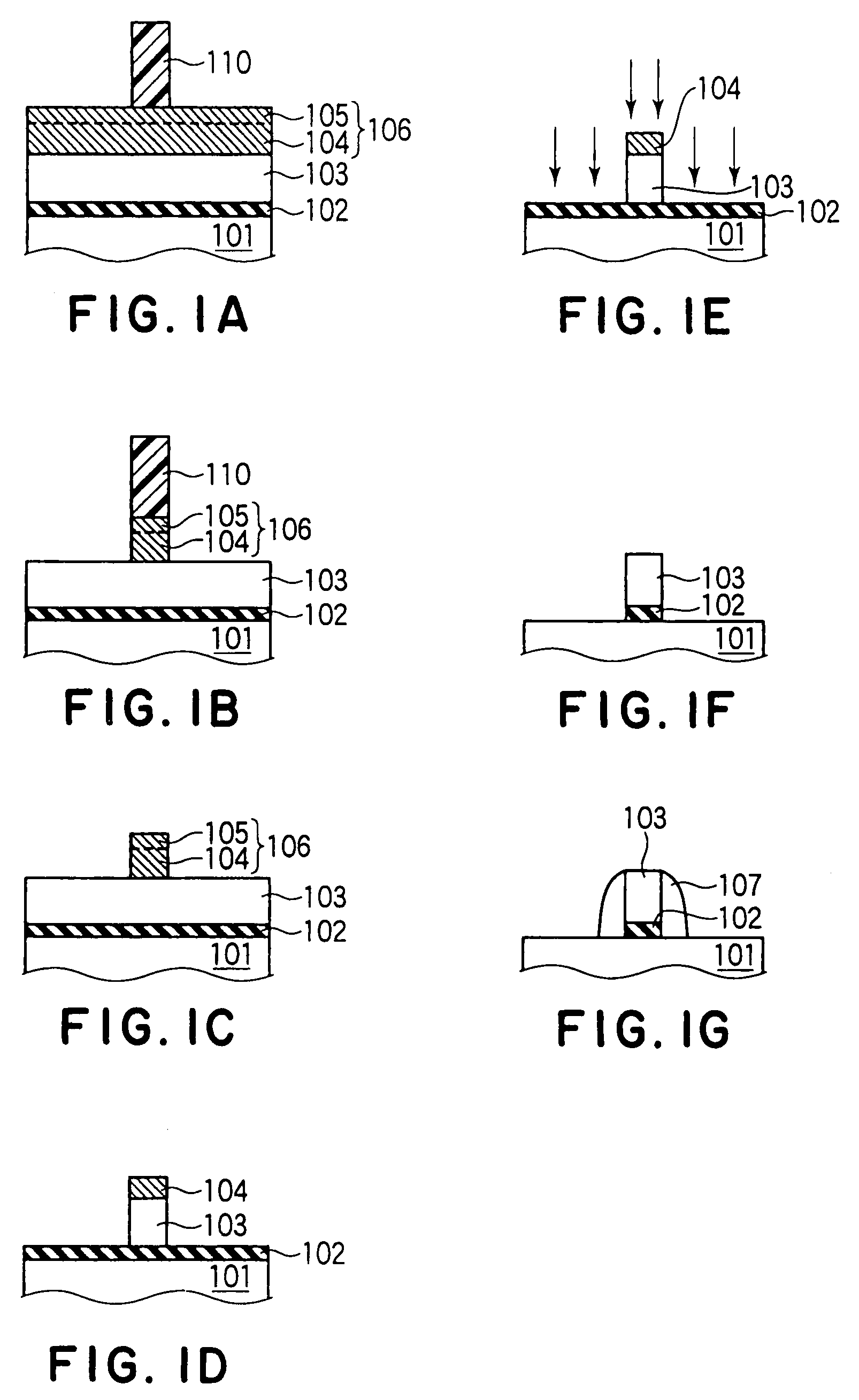

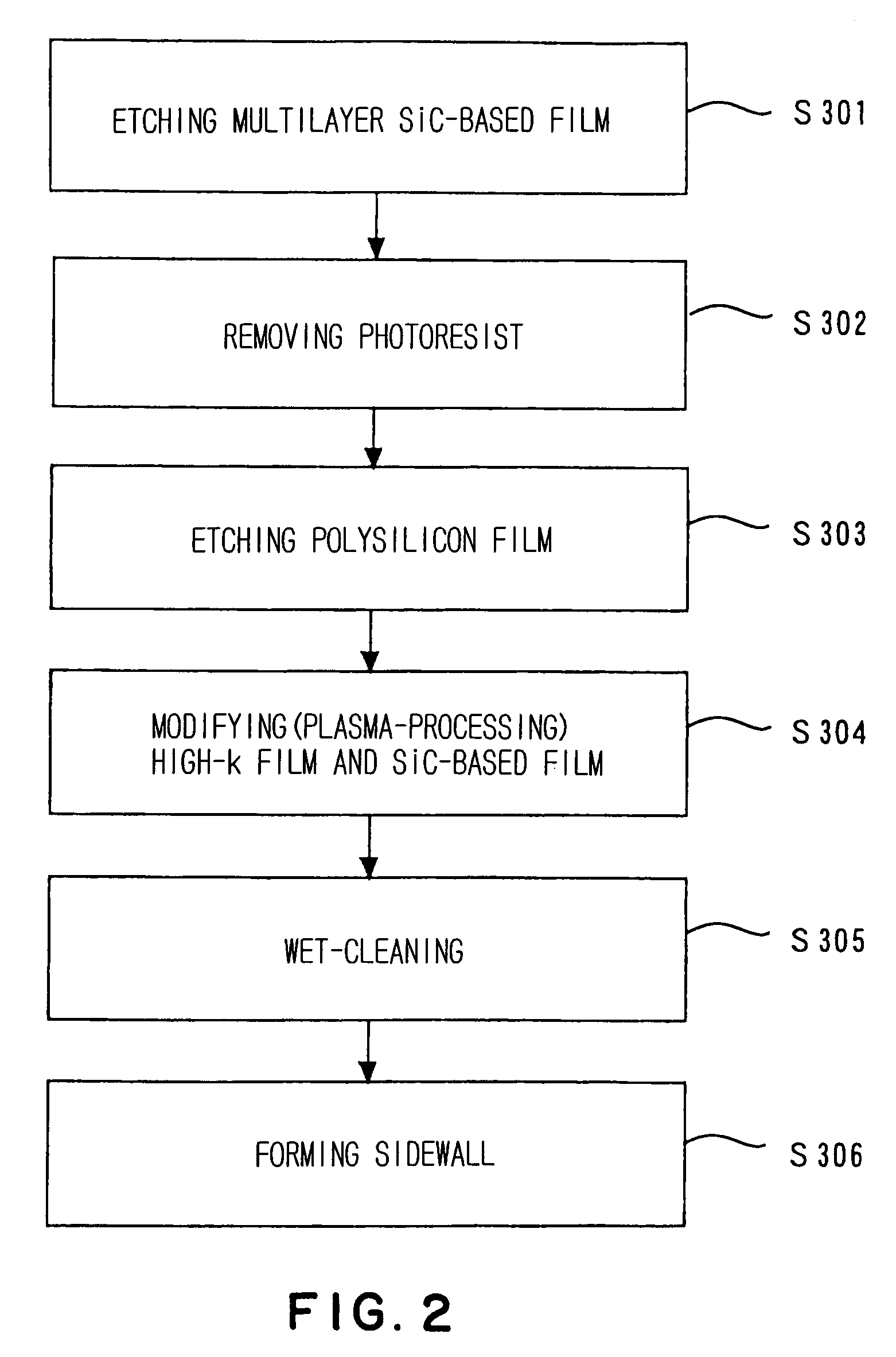

Method for Manufacturing Semiconductor Device

ActiveUS20080268655A1Efficient solutionExemption stepsSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

The present invention is a method of manufacturing a semiconductor device from a layered body including: a semiconductor substrate; a high dielectric film formed on the semiconductor substrate; and an SiC-based film formed on a position upper than the high dielectric film, the SiC-based film having an anti-reflective function and a hardmask function. The present invention comprises a plasma-processing step for plasma-processing the SiC-based film and the high dielectric film to modify the SiC-based film and the high dielectric film by an action of a plasma; and a cleaning step for wet-cleaning the SiC-based film and the high dielectric film modified in the plasma-processing step to collectively remove the SiC-based film and the high dielectric film.

Owner:TOKYO ELECTRON LTD

Method for treating electrophotographic carrier, method for producing electrophotographic carrier, core material and carrier

InactiveUS20110136057A1Efficient decompositionReliable separationSolvent extractionDevelopersMaterial SeparationChemistry

A method for treating an electrophotographic carrier, including treating, with supercritical pure water, the electrophotographic carrier containing at least a core material and a coating layer, so that the coating layer is separated from the core material, wherein the supercritical pure water is obtained by bringing, into a supercritical state, pure water having an electrical conductivity at 25° C. of 1 μS·cm or lower.

Owner:RICOH KK

Fish processing system and method

ActiveUS20130059512A1Efficient and reliable removalEasy to cleanFish processingFish processingEngineering

Owner:RYCO EQUIP

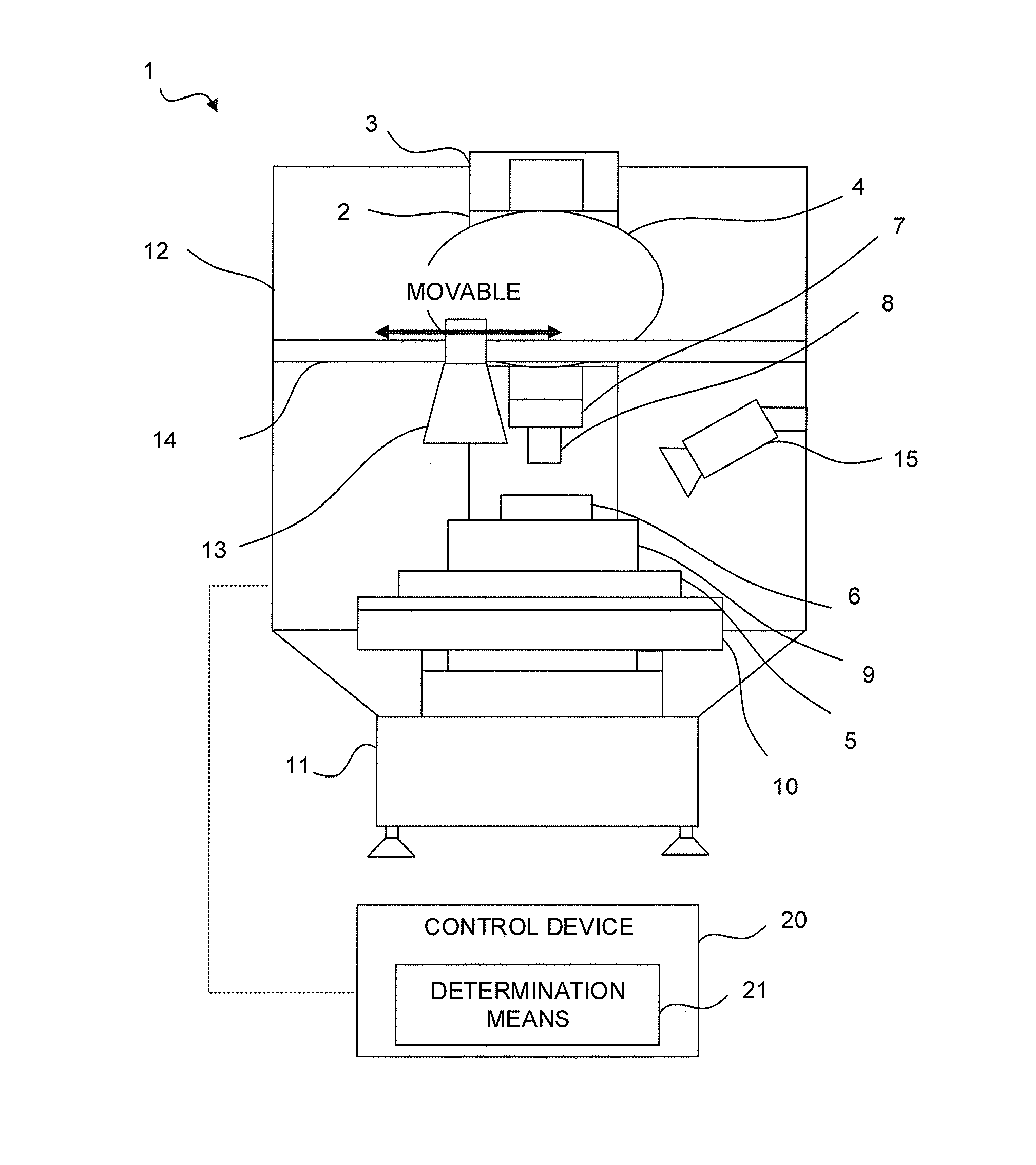

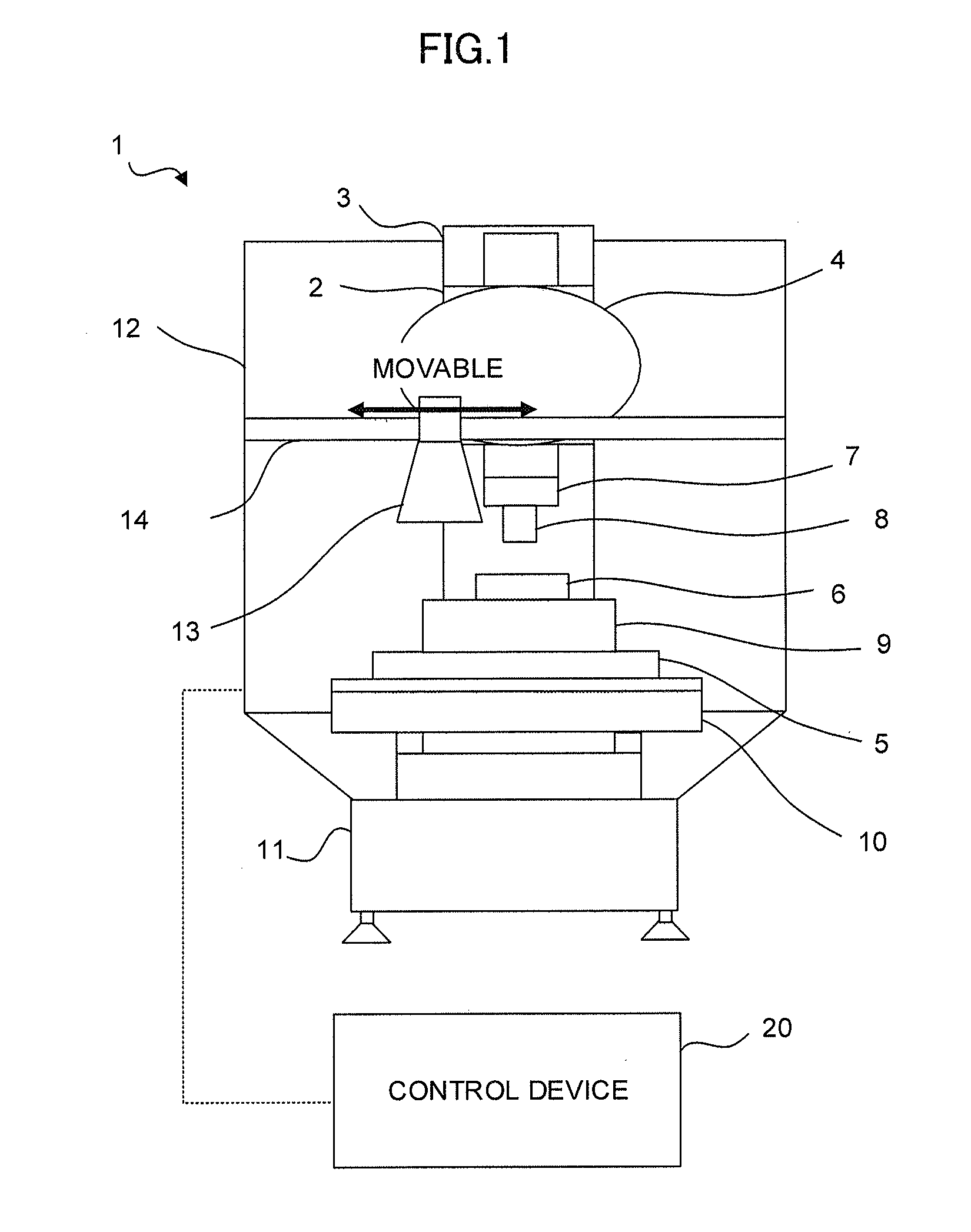

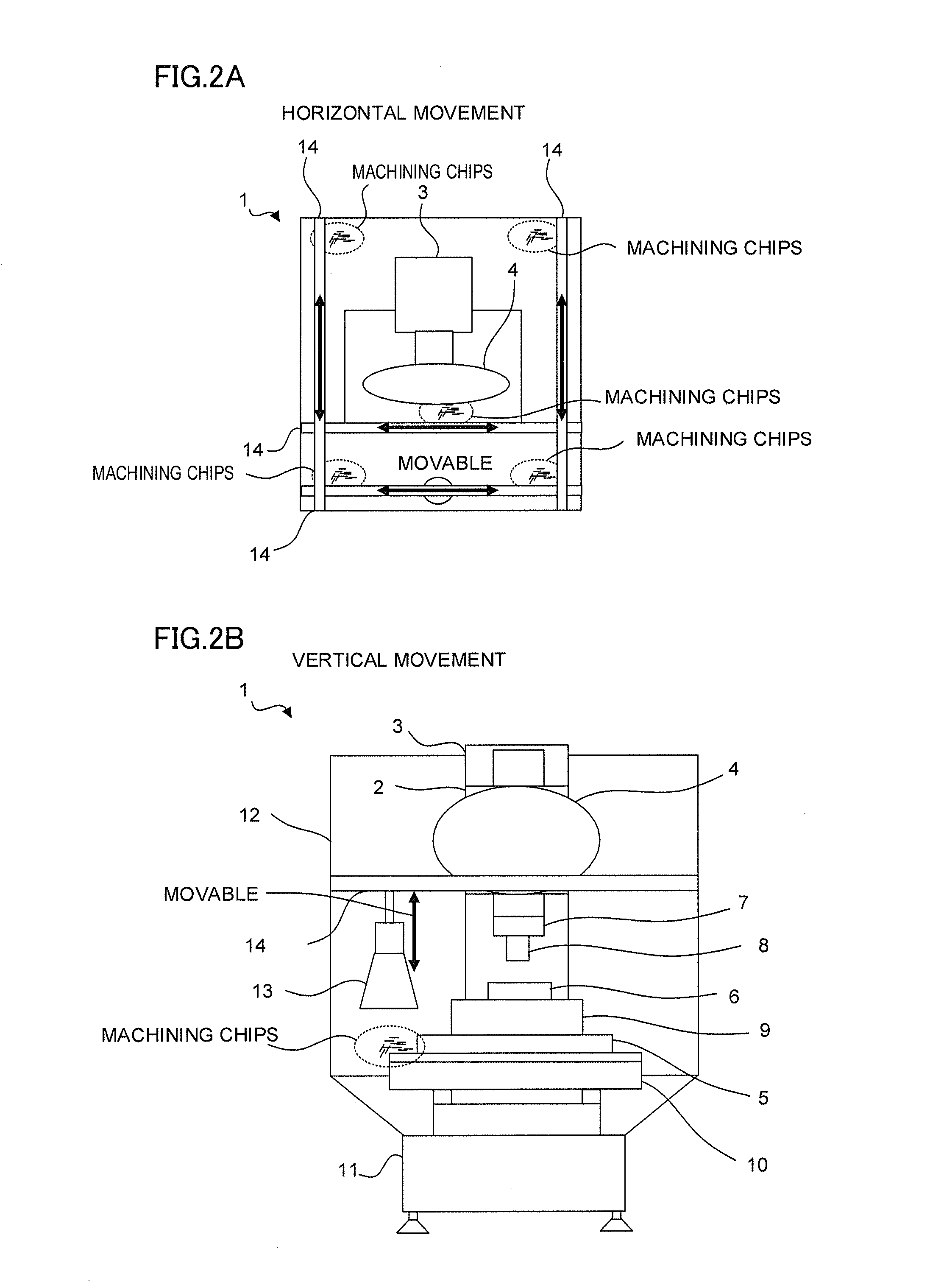

Processing machine including electric discharger

ActiveUS20170013700A1Efficient removalEfficient and reliable removalSemiconductor/solid-state device manufacturingMaintainance and safety accessoriesEngineeringMachining

In a processing machine according to the present invention, an electric discharger to remove static electricity from a charged work piece or charged machining chips is installed on a movement means including a beam supported by a constituting member of the processing machine and a power source installed in the beam. By making the electric discharger movable inside and outside the processing machine, the static electricity can be removed from machining chips and the like in a plurality of areas needing removal of the static electricity using a small number of the electric dischargers.

Owner:FANUC LTD

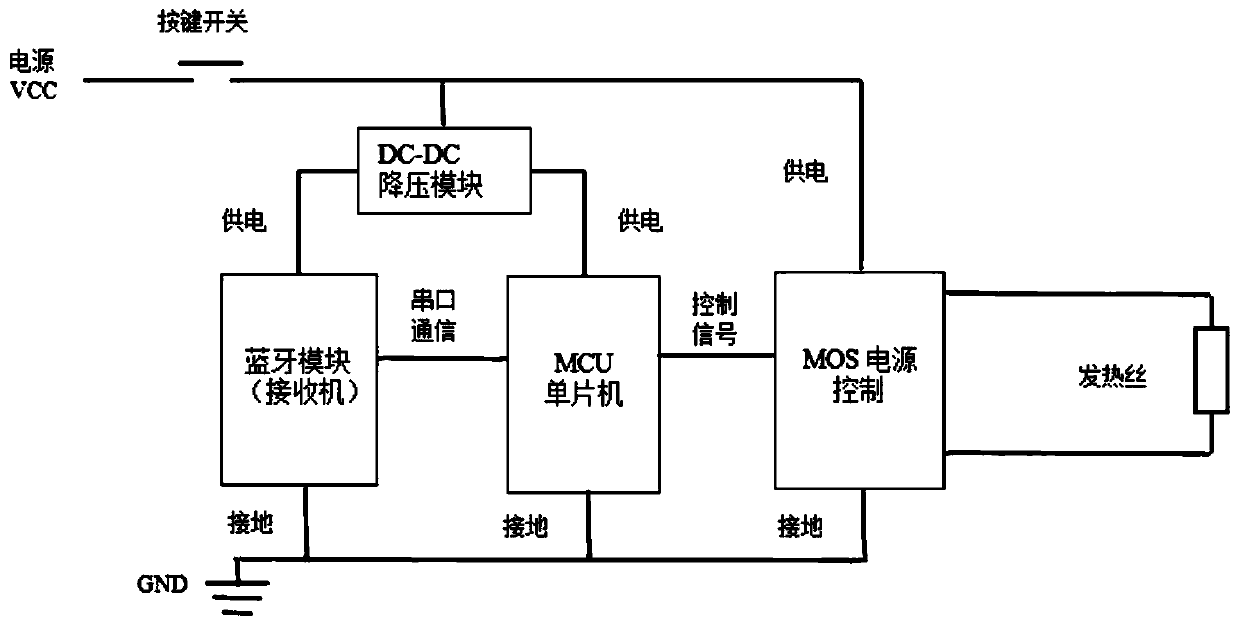

Hand-held power transmission line floating object removing device

InactiveCN110459981AEfficient and reliable removalQuick clearApparatus for overhead lines/cablesPower batteryElectricity

The invention provides a hand-held transmission line floating object removing device which comprises an insulated operating rod, a main device box of the device, a heating wire and a heating wire support frame. The tail end of the insulated operating rod is connected with the bottom of the main device box of the device. The top of the main device box of the device is mechanically connected with the heating wire support frame. Two ends of the heating wire are wound around the tail end of the heating wire support frame. The heating wire is electrically connected with the main device box of the device. The main device box of the device comprises a device control circuit and a power battery. The power battery is electrically connected with the device control circuit. The device control circuitis electrically connected with the heating wire. While being safe and convenient to operate, the device meets the requirement for efficiently cleaning floating objects on a line. The risk of an efficient trip is avoided. The operation reliability of the transmission line is improved.

Owner:GUANGDONG POWER GRID CO LTD +1

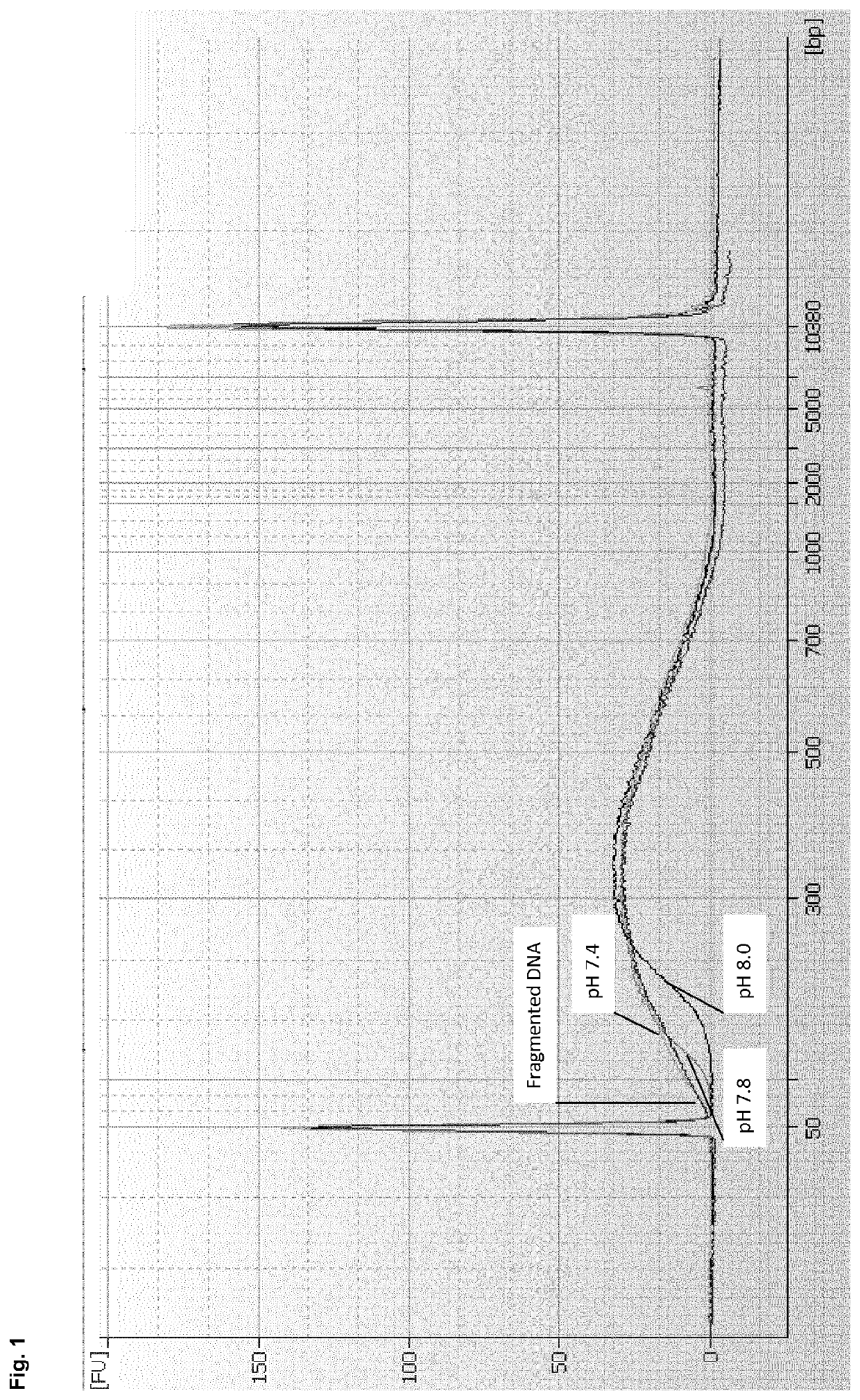

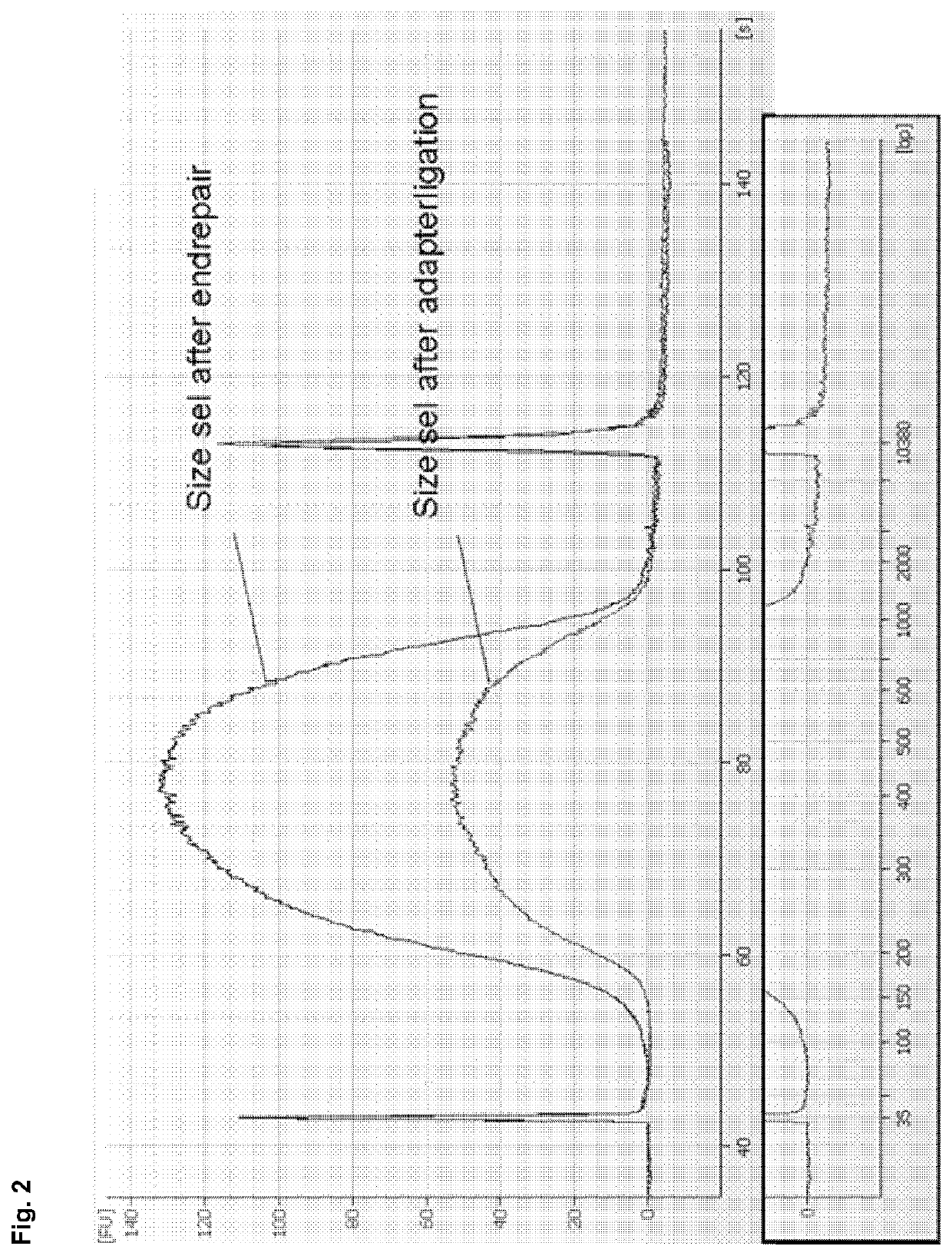

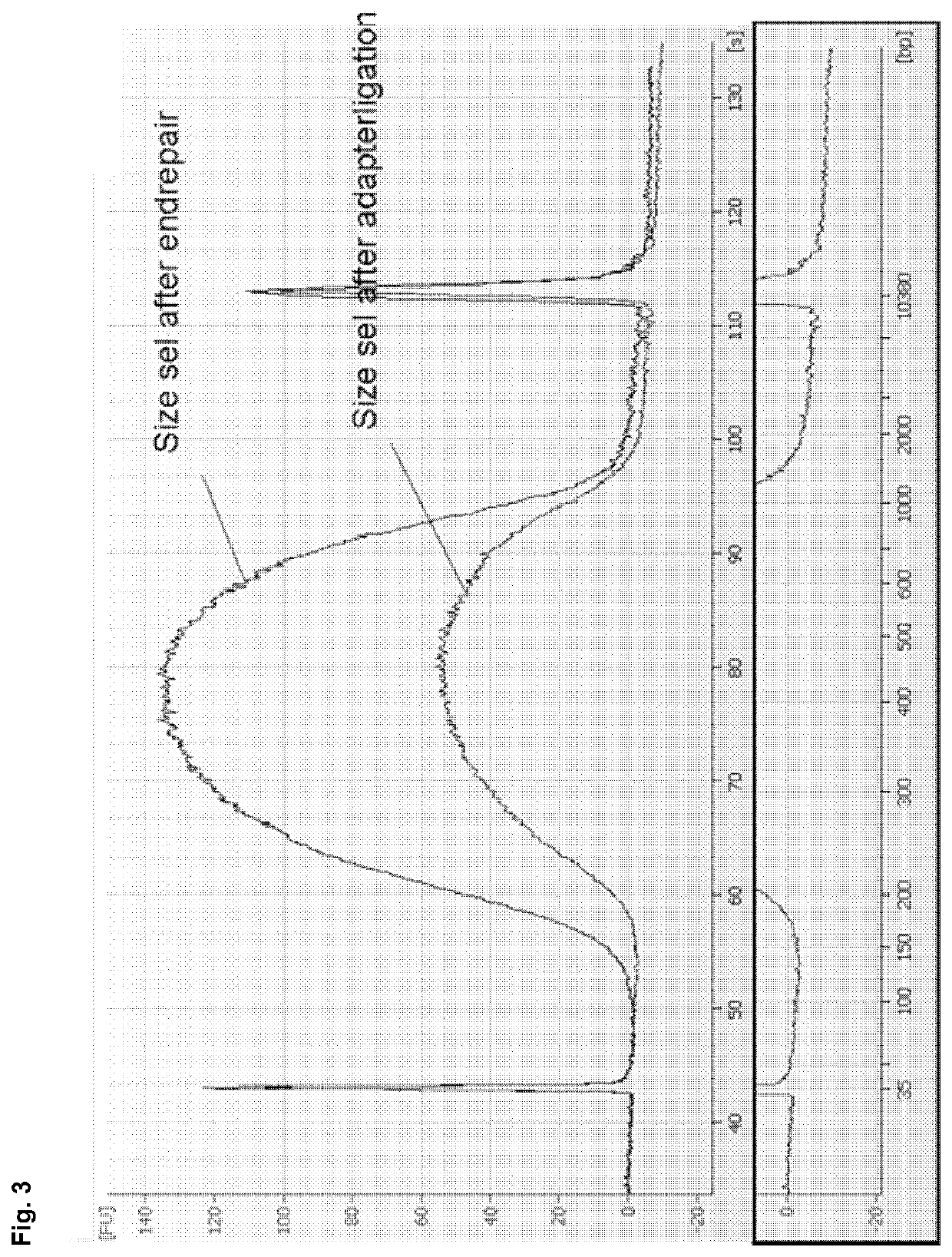

Method for separating DNA by size

ActiveUS10745686B2Proper selectionEfficient and reliable removalMicrobiological testing/measurementBiological testingBuffering agentChaotropic agent

The present invention provides method for isolating DNA molecules having a size above a certain cut-off value from a DNA containing sample, comprising a) contacting the sample with a binding buffer which comprises a chaotropic agent and a buffering agent to provide a binding mixture and binding DNA molecules having a size above the cut-off value to a binding matrix which has a silicon containing surface, wherein the cut-off value is determined by the pH value of the binding mixture; b) separating the bound DNA from the remaining sample; c) optionally washing the bound DNA; and d) optionally eluting the bound DNA from the binding matrix. Said method allows the size selective purification of DNA molecules.

Owner:QIAGEN GMBH

Novel long-acting coating technology of oil and gas equipment

ActiveCN103537421AEfficient and reliable removalAvoid quality hazardsLiquid surface applicatorsCoatingsStructure of the EarthLacquer

Disclosed is a novel long-acting coating technology of oil and gas equipment. The novel long-acting coating technology includes the steps that first, surface treatment is conducted, an angular finishing grinder is used for treatment at the positions which are simple in structure, a pneumatic type steel needle impacting brush is used for treatment at the positions of cracks and dead angles for connection of the equipment, and old paint films and oxidation substances on the surface of the equipment can be efficiently and reliably removed; second, ground coat paint is sprayed, before spraying, in the first place, the dead angles and cracks of the equipment have to be painted through a writing brush and a row of brushes, and the film thickness of the positions is made to meet design requirements; third, plastering and leveling are carried out; fourth, intermediate paint is sprayed, and the intermediate paint is sprayed in the way of executing the second step repeatedly; fifth, defects are found visually, and supplementary plastering and one more leveling are achieved; sixth, finish paint is sprayed, and the finish paint is sprayed in the way of executing the second step repeatedly. Repeated painting is conducted at the dead angles and cracks of the equipment by the adoption of the writing brush, the row of brushes and the like, a paint protective film can be formed, hence, potential quality hazards caused by leaky spaying of the dead angles and cracks of the equipment or poor spraying can be eradicated, and therefore the service life of the equipment is greatly prolonged.

Owner:冯学良

Method for manufacturing semiconductor device

ActiveUS7897498B2Efficient solutionExemption stepsSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringReflection function

Owner:TOKYO ELECTRON LTD

Heating equipment of oil filtering machine

InactiveCN105771401AExtend heating timeImprove heating efficiencyFiltration circuitsTemperature controlOil can

The invention discloses heating equipment of oil filtering machine. The heating equipment comprises a heater and a particle type separator. The particle type separator is arranged in vacuum separating equipment of oil filtering machine and is externally connected to the heater; the other end of the heater is connected to an oil supply facility, and the heater is provided with a fuzzy temperature control instrument. By using a fuzzy temperature control technology, the heating time and technology for purifying oil are improved, the oil temperature can be controlled under 70 DEG C, the oil quality can be maintained, the structure of oil molecules is not destroyed, the heated oil can be effectively discharged by the particle type heater, the oil is stirred in the vacuum space of the vacuum separating equipment so as to separate impurities (water and gas) from oil, and the disqualified transformer oil is processed so as to obtain an oil product that can meet the national and international standards.

Owner:HARBIN HONGWANZHI SCI & TECH DEV

Reactor cleaning apparatus

ActiveUS7975709B2Easy and reliable removalEfficient and reliable removalLiquid surface applicatorsSiliconNuclear engineeringHigh pressure

In a reactor cleaning apparatus 1 which cleans an inner wall surface 72 of a reactor 70 which generates polycrystalline silicon, a bell jar of the reactor 70 has a dual structure, a through hole 11 is formed along a vertical direction at a central portion of a substantially disc-like tray 10 placed in a horizontal state, a flange portion 13 in which an opening edge of the reactor 70 is placed is formed at an outer peripheral portion of the tray 10, a shaft 20 is provided through the through hole 11 of the tray 10 so as to be rotatable and movable in the vertical direction, a nozzle device 50 which sprays a cleaning water at high pressure in three-dimensional directions is provided at an upper end of the shaft 20, a drive mechanism 30 which rotates the shaft 20 and moves the shaft in the vertical direction is provided at a base end of the shaft 20, and steam piping 62 capable of supplying the steam within the bell jar of the reactor 70 is provided.

Owner:HIGH-PURITY SILICON CORP

Long-term coating process for metal surface of oil and gas equipment

ActiveCN103537421BEfficient and reliable removalAvoid quality hazardsLiquid surface applicatorsCoatingsStructure of the EarthPetroleum

Disclosed is a novel long-acting coating technology of oil and gas equipment. The novel long-acting coating technology includes the steps that first, surface treatment is conducted, an angular finishing grinder is used for treatment at the positions which are simple in structure, a pneumatic type steel needle impacting brush is used for treatment at the positions of cracks and dead angles for connection of the equipment, and old paint films and oxidation substances on the surface of the equipment can be efficiently and reliably removed; second, ground coat paint is sprayed, before spraying, in the first place, the dead angles and cracks of the equipment have to be painted through a writing brush and a row of brushes, and the film thickness of the positions is made to meet design requirements; third, plastering and leveling are carried out; fourth, intermediate paint is sprayed, and the intermediate paint is sprayed in the way of executing the second step repeatedly; fifth, defects are found visually, and supplementary plastering and one more leveling are achieved; sixth, finish paint is sprayed, and the finish paint is sprayed in the way of executing the second step repeatedly. Repeated painting is conducted at the dead angles and cracks of the equipment by the adoption of the writing brush, the row of brushes and the like, a paint protective film can be formed, hence, potential quality hazards caused by leaky spaying of the dead angles and cracks of the equipment or poor spraying can be eradicated, and therefore the service life of the equipment is greatly prolonged.

Owner:冯学良

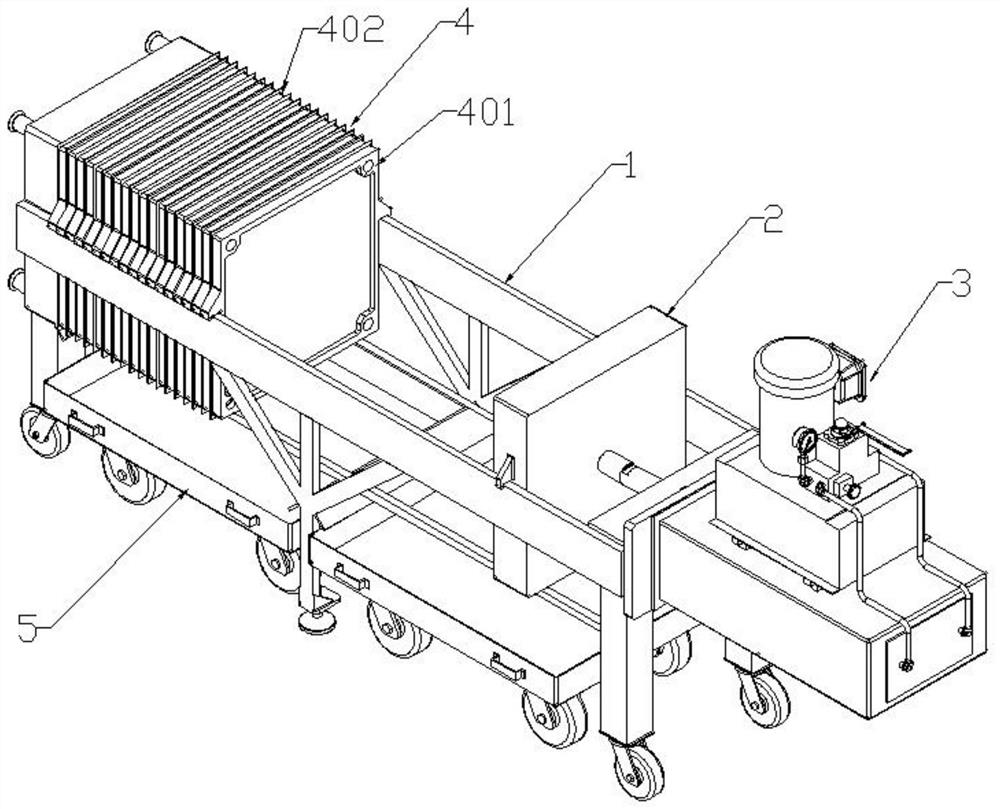

Refining method of rice bran oil retaining oryzanol

PendingCN112899078ATransparent colorHigh in oryzanolFatty-oils/fats refiningFiltrationProcess engineering

The invention discloses a refining method of rice bran oil retaining oryzanol. The refining method comprises the steps of 1, conducting filter pressing impurity removal; 2, degumming with acid and alkali in sequence; 3, pre-decolorizing by using a small amount of activated clay, and then adding a large amount of activated clay under vacuum and high temperature for re-decolorizing; 4, performing low-temperature crystallization, filtration and dewaxing; 5, performing high-temperature steam stripping deacidification and deodorization; and 6, performing low-temperature low-speed stirring crystallization filter pressing degreasing. Filter pressing impurity removal equipment used in the first step comprises a machine frame component, a material pressing plate assembly, a pneumatic mechanism, a filter frame assembly and a material receiving trolley, the pneumatic mechanism is located on one side of the machine frame component, the filter frame assembly is located above the other side of the machine frame component, the material pressing plate assembly is located between the pneumatic mechanism and the filter frame assembly, and the material receiving trolley is oppositely arranged below the machine frame component. The problems that rice bran oil is large in acidity, and a large amount of oryzanol is decomposed and consumed in the refining process in the prior art are solved, and the nutritive value of the rice bran oil is increased.

Owner:BENGBU QIONGHUAI GRAIN & OIL

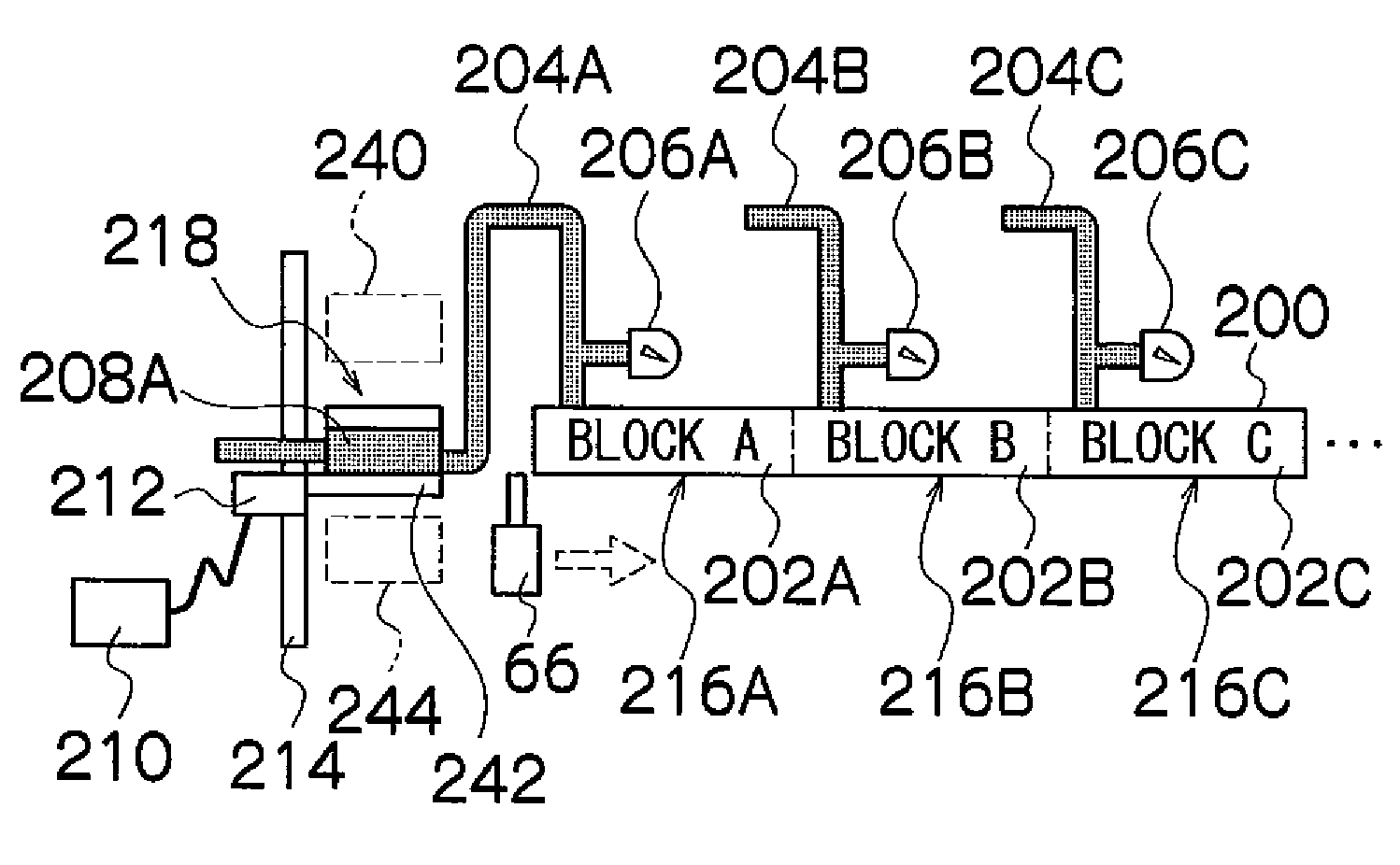

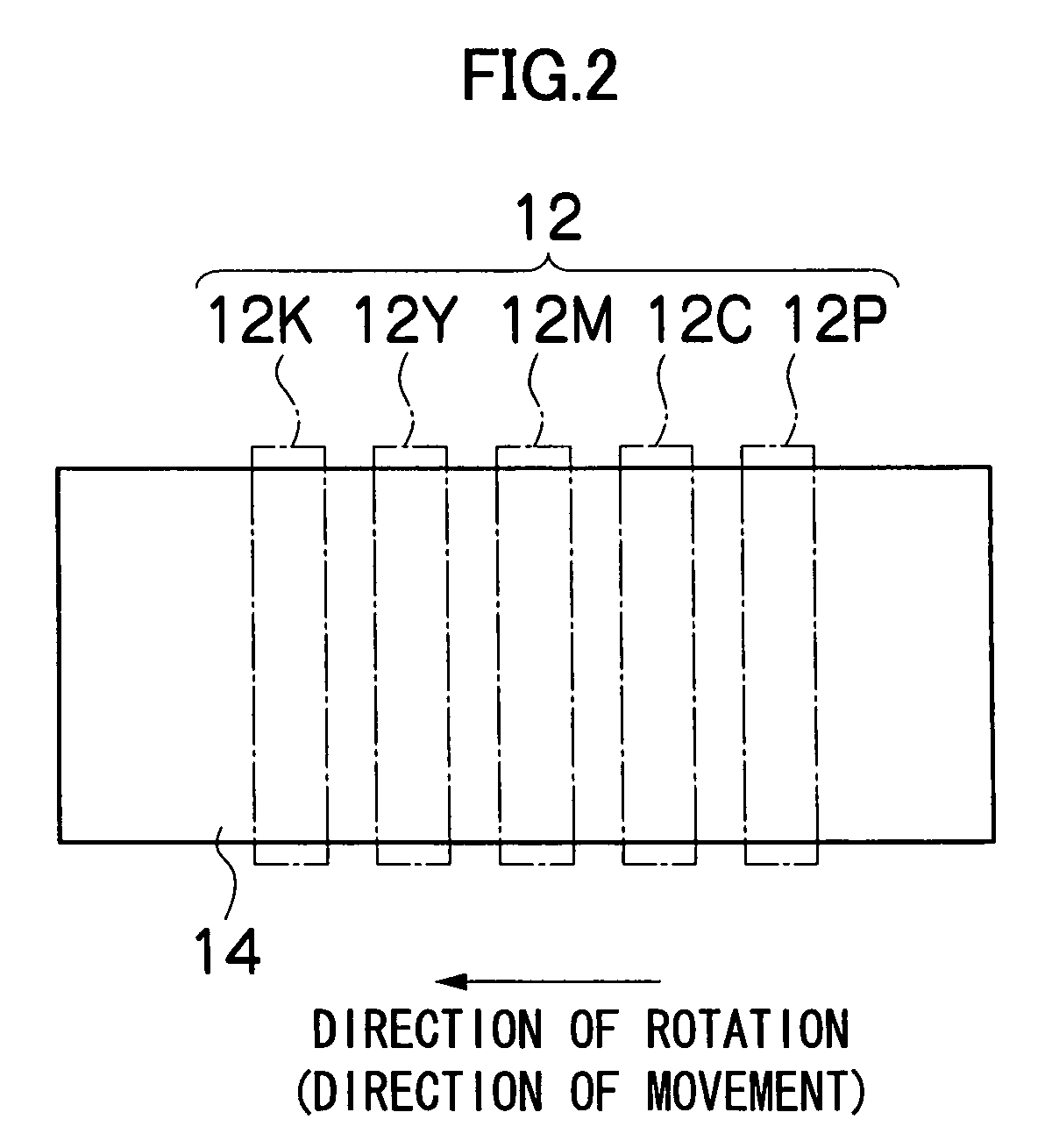

Inkjet recording apparatus and cleaning method

An inkjet recording apparatus that includes an intermediate transfer body that has an image forming surface including an image forming region on which an image is formed by means of the ink droplets ejected from an ink ejection head and a cleaning device which makes contact with the image forming surface of the intermediate transfer body to wipe off and remove adhering material attached to the intermediate transfer body. A second cleaning device makes contact with the first cleaning device to remove adhering material attached to the first cleaning device. An ejection control device controls ink ejection from the head and a recovery device is provided which recovers the adhering material removed by the second cleaning device.

Owner:FUJIFILM CORP

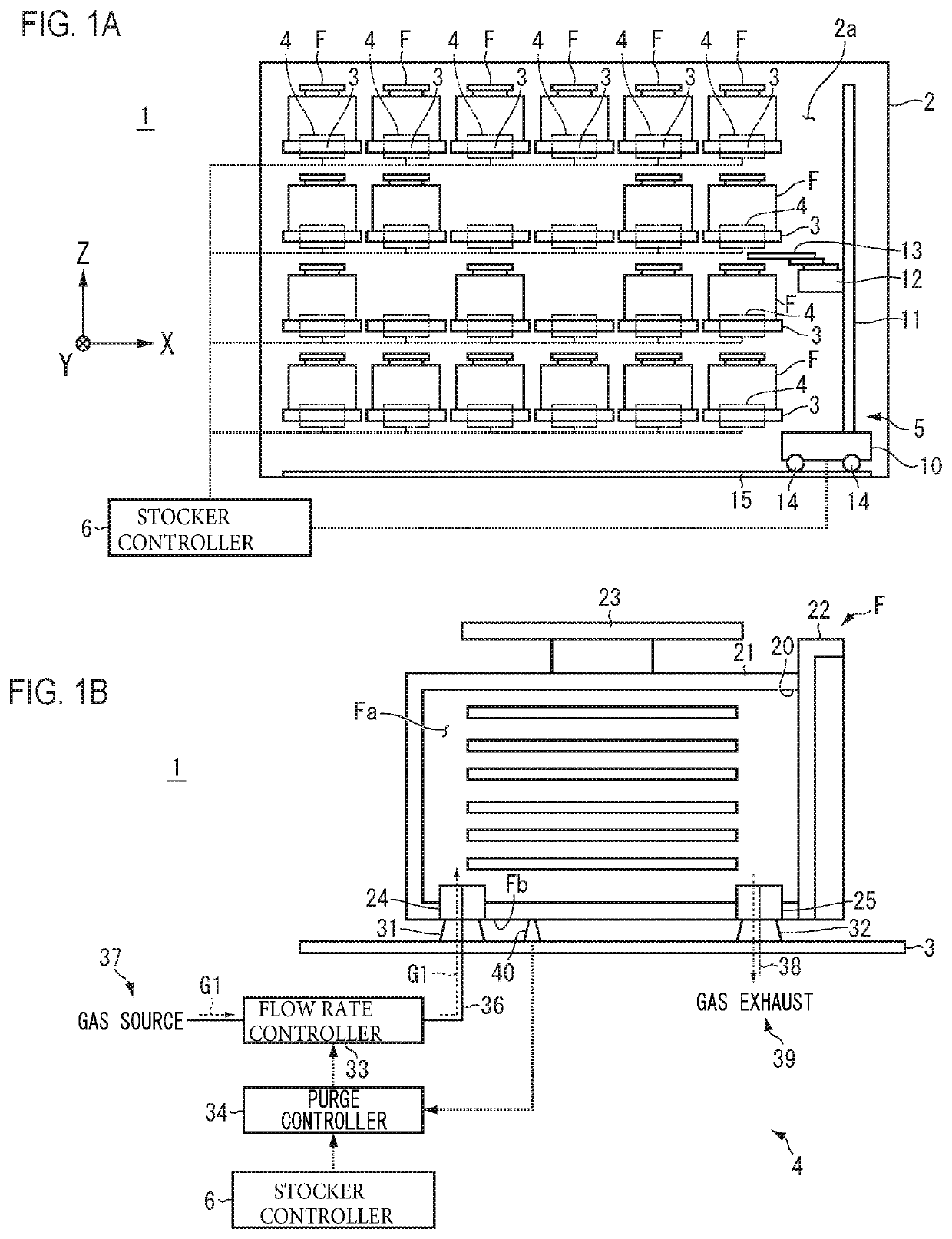

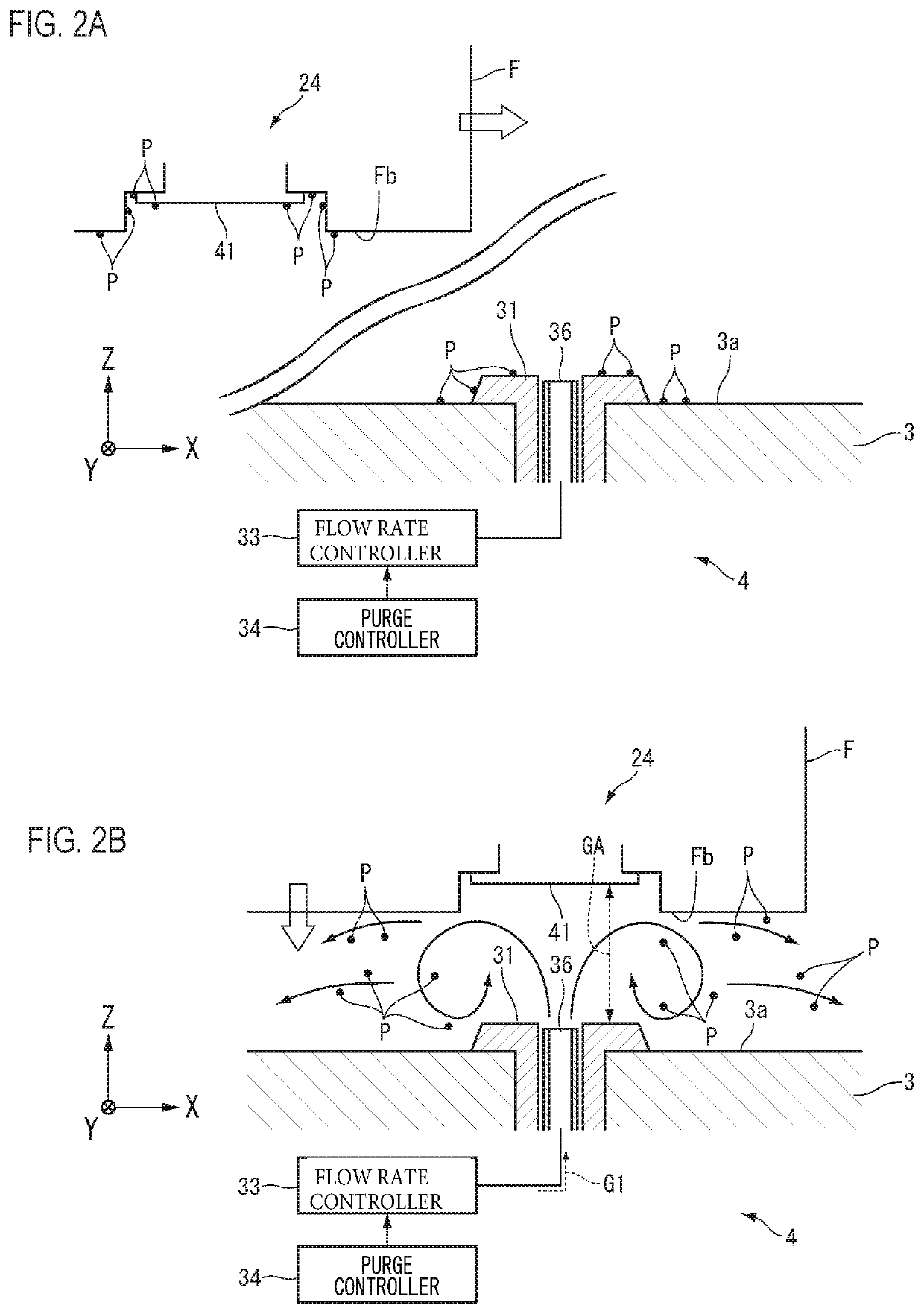

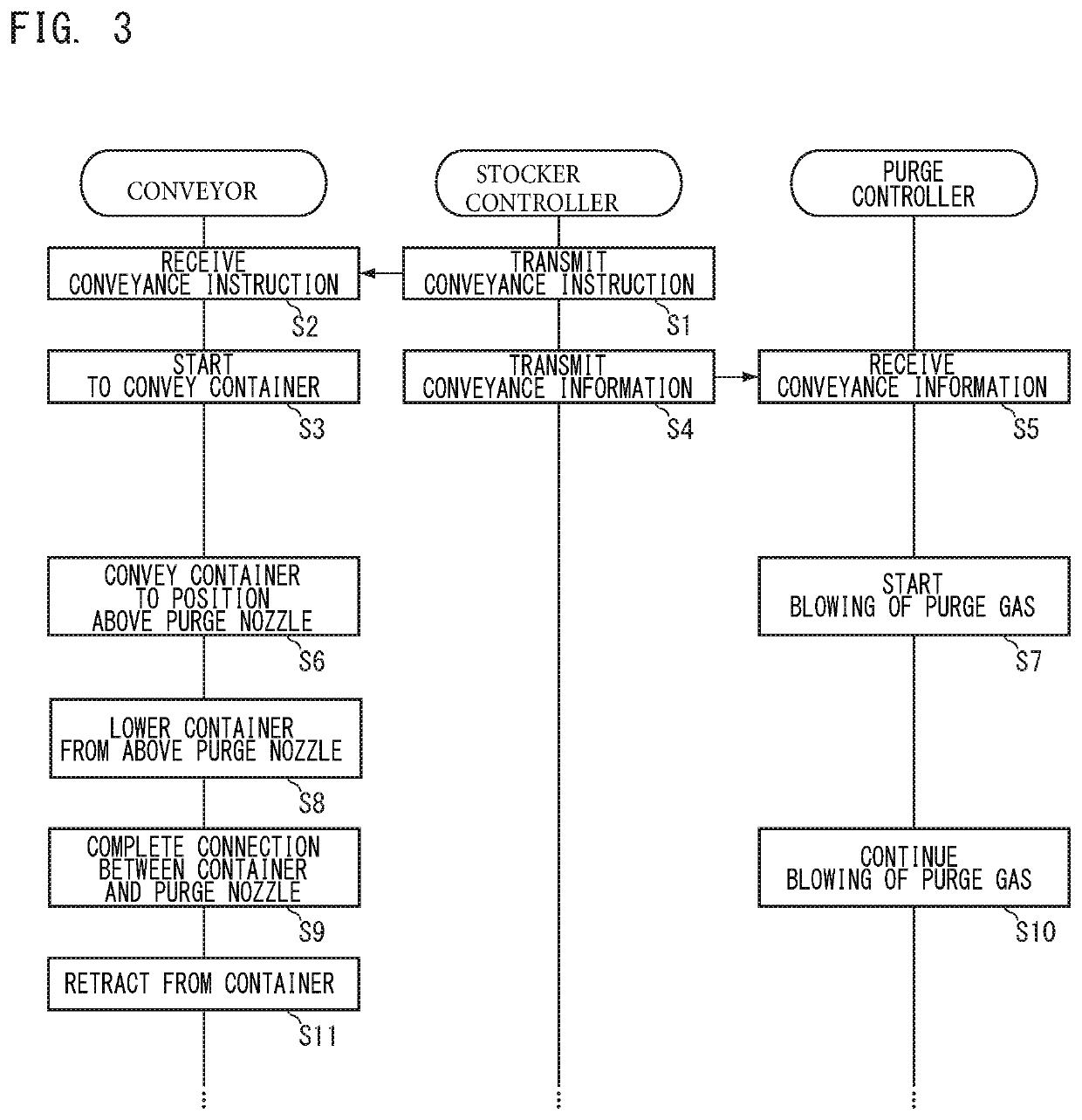

Purge device, purge stocker, and cleaning method

ActiveUS10610905B2Simplify device configurationHigh purityConveyorsHollow article cleaningEngineeringMechanics

A purge device is capable of removing particles adhering to a gas introduction port in a container or on surrounding areas of a purge nozzle. The purge device includes a nozzle that is able to blow a gas, and a purge controller that controls the nozzle to blow the gas therethrough in a state in which a bottom surface of a container to be purged faces the nozzle.

Owner:MURATA MASCH LTD

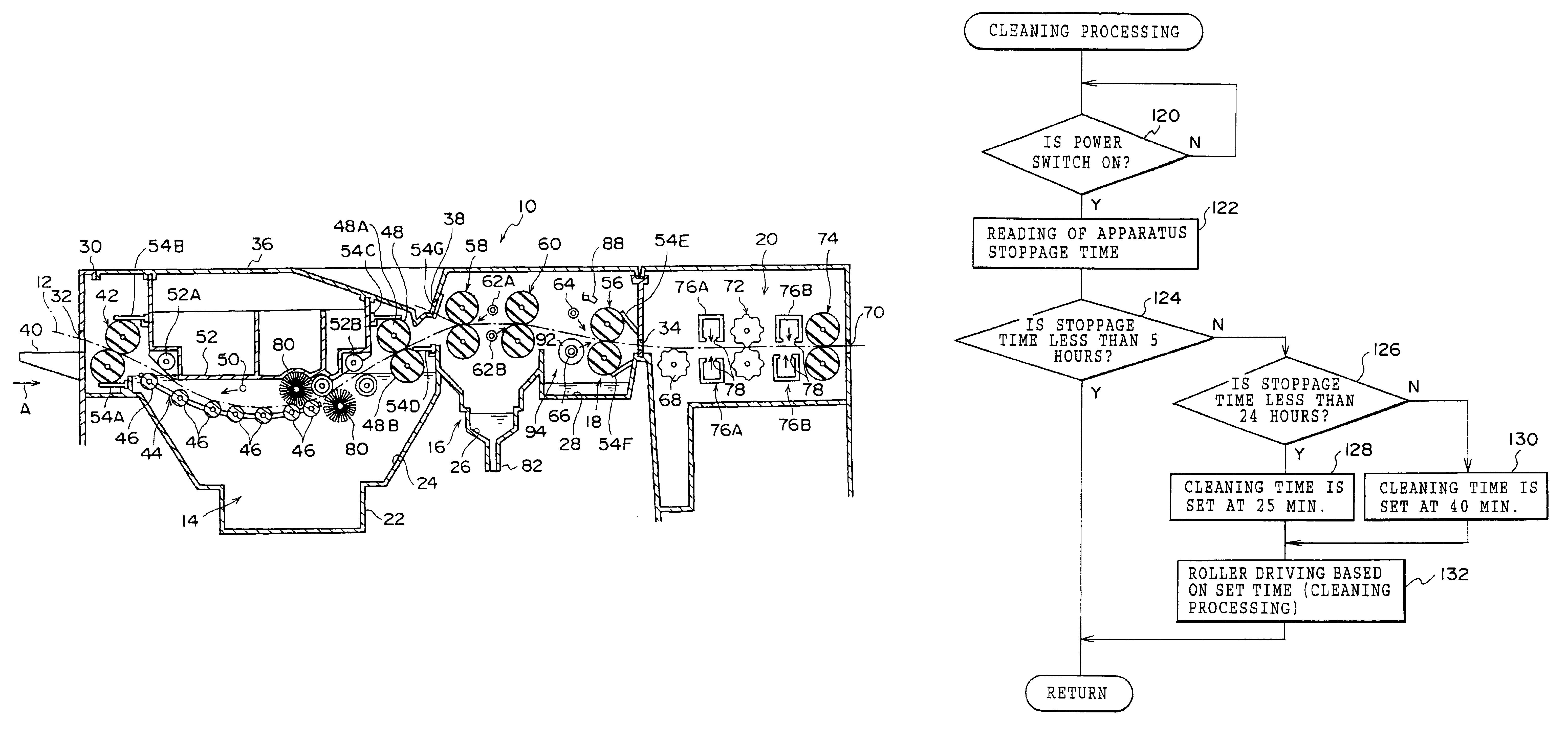

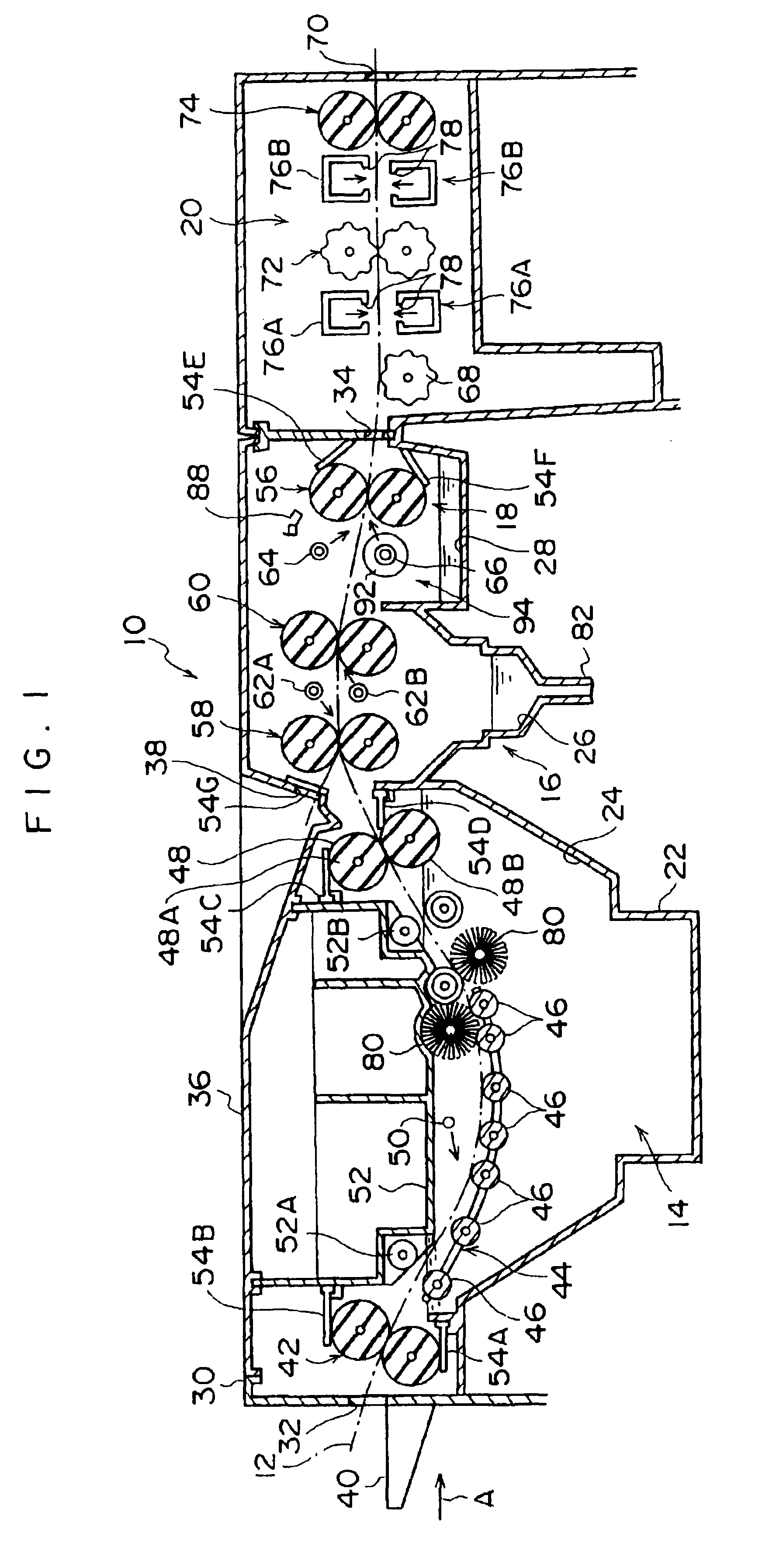

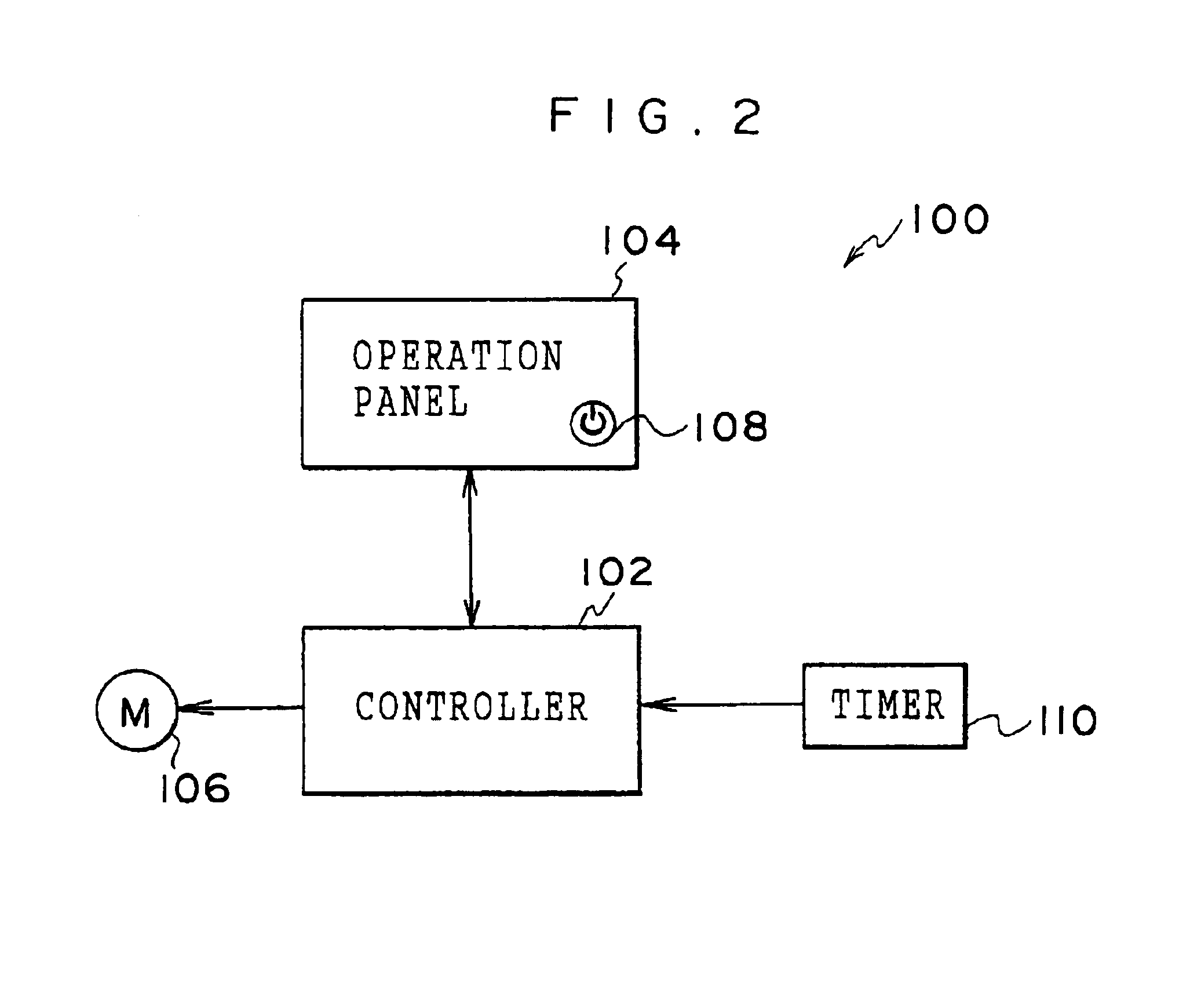

Printing plate processing apparatus

InactiveUS6902330B2Finish quality be deteriorateEfficient and reliable removalLiquid processing by liquid spraysAddressographsEngineeringMechanical engineering

A printing plate processing apparatus provides a step in which a printing plate which has undergone image exposure is processed by being immersed in a developing solution, and the printing plate is delivered while the developing solution is being squeezed out from the printing plate by a conveying roller pair which is partially immersed in the developing solution. A stoppage time of the apparatus is measured, and the conveying roller pair is driven to rotate for an amount of time set in accordance with a measured result of the stoppage time when operation of the apparatus is started, thereby allowing the conveying rollers to be cleaned. A concentration of carbon dioxide in an environment in which the apparatus is installed is detected, and based on the detected result and the measured result of the apparatus stoppage time, the driving time of the conveying roller pair is set.

Owner:FUJIFILM CORP +1

Manufacturing method of leadframe and semiconductor device

ActiveUS8349656B2Avoid deformationEfficient and reliable removalSemiconductor/solid-state device detailsSolid-state devicesResistEtching

In order to remove plating burrs generated in etching step, there is provided a manufacturing method of semiconductor devices on each of unit leadframes in a leadframe material in which a plurality of the unit leadframes are arranged in plural rows or a single row, wherein at least two types of plating burr removals are conducted after a half-etching is performed onto a front surface side of the leadframe material, using a first plating layer as resist film.

Owner:ADVANCED SEMICON ENG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com