Silicon dioxide solution preparation method, grinding fluid, and manufacture method of glass substrate

A silicon dioxide and solution technology, applied in chemical instruments and methods, record carrier manufacturing, other chemical processes, etc., can solve the problems of glass substrate damage, filter clogging, poor yield, etc., and achieve excellent smoothness, foreign matter and Damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] (Preparation of Silica Solution)

[0045] The method for preparing a silica solution of the present invention can be used to remove foreign matter in a silica solution (hereinafter also referred to as a solution) obtained by dispersing silica particles and foreign matter in a solvent such as water or an organic solvent. In the present invention, the silica particles and foreign matter mainly exist dispersed in the solvent, but they may be partially dissolved in the solvent. The silica solution may contain additives or impurities other than silica particles and foreign matter. The solvent is not particularly limited, and examples thereof include water, alcohols such as methanol and isopropanol, organic solvents such as ethylene glycol and propylene glycol, and the like. Water is preferable from the viewpoint of easily dispersing the silica particles, and pure water, ultrapure water, ion-exchanged water, and the like are preferable from the viewpoint of less influence on...

Embodiment

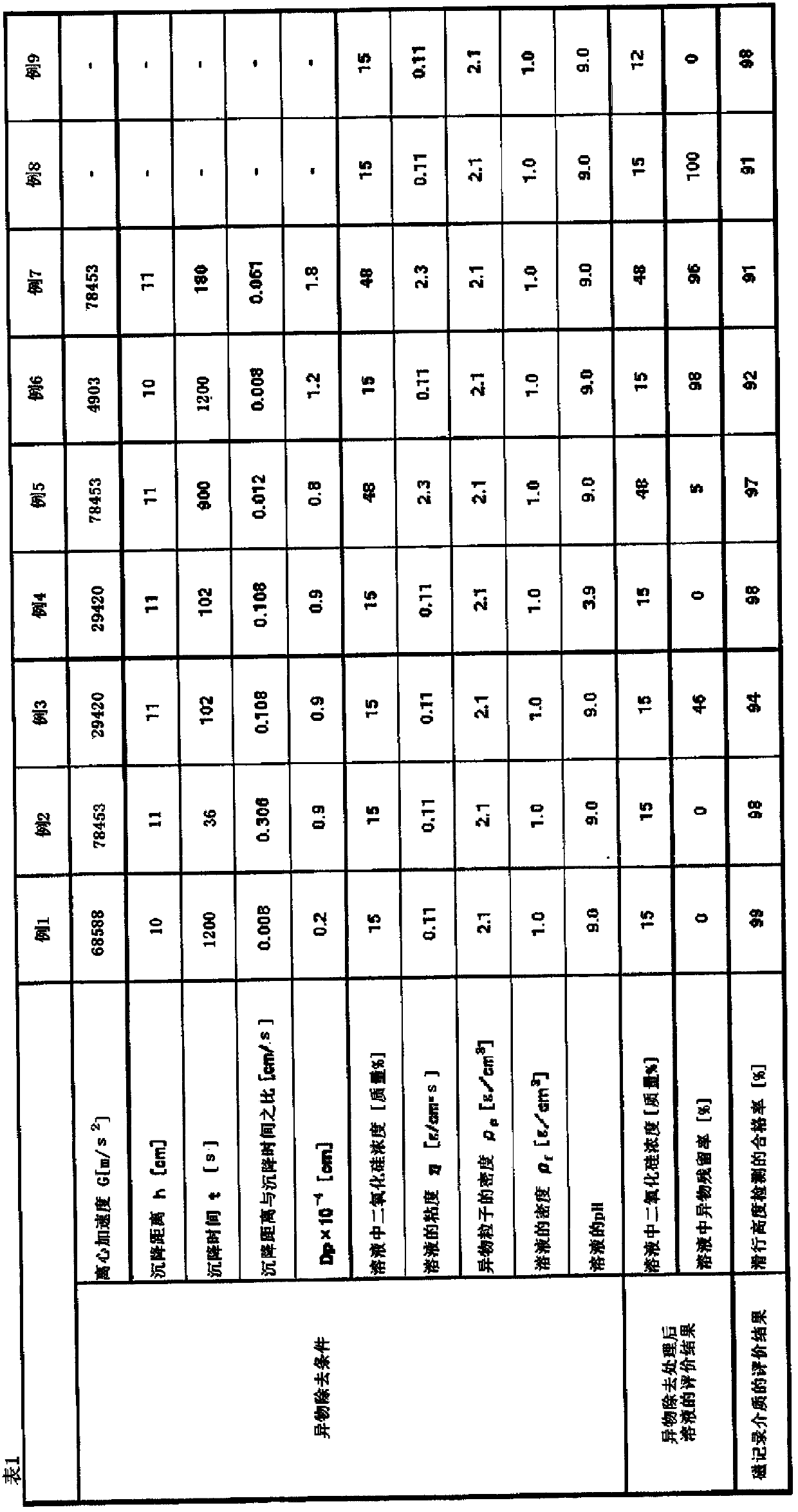

[0085] Hereinafter, examples of the present invention will be specifically described, but the present invention is not limited to the examples. In addition, among the following Examples 1 to 9, Examples 1 to 5 are examples of the present invention, and Examples 6 to 9 are comparative examples.

[0086] In Examples 1 to 9, the foreign matter to be removed is diatomite, and its density ρ p 2.1 (g / cm 3 ), the solvent is water, the density ρ f 1(g / cm 3 ).

[0087] (Preparation of Silica Solution)

[0088] In Examples 1 to 9, a solution obtained by diluting a colloidal silica solution (a silica solution having an average primary particle diameter of silica particles of 30 nm) with pure water was used as the silica solution.

[0089] (Foreign matter removal treatment)

[0090] The equipment used in the foreign matter removal treatment is shown below.

[0091] Centrifugal separator A: (batch processing type, large-capacity cooling centrifuge HL-7α (manufactured by Coxan Co., L...

example 1

[0094] The colloidal silica solution was diluted with pure water so that the concentration of silica in the solution was 15% by mass, and sodium hydroxide was added to adjust the pH to 9. Put this solution into the rotor of centrifuge A until the height is 10cm (equivalent to the sedimentation distance), at 68588 (m / s 2 ) for 20 minutes (corresponding to the settling time), and the resulting solution was referred to as silica solution 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com