Free forging intelligent production system and method

An intelligent production and free technology, applied in general control system, control/regulation system, drive device of forging press, etc., can solve obstacles to intelligent production of spindle free forging, difficulty in achieving consistent processing quality, and stable quality of engine spindle Improve the accuracy and assembly quality, shorten the assembly time, and reduce the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0044] The invention provides an intelligent free forging production unit aiming at the problem that the intellectualization process of the forging process of the engine main shaft is hindered, so as to improve the intellectualization degree of the forging production of the main shaft.

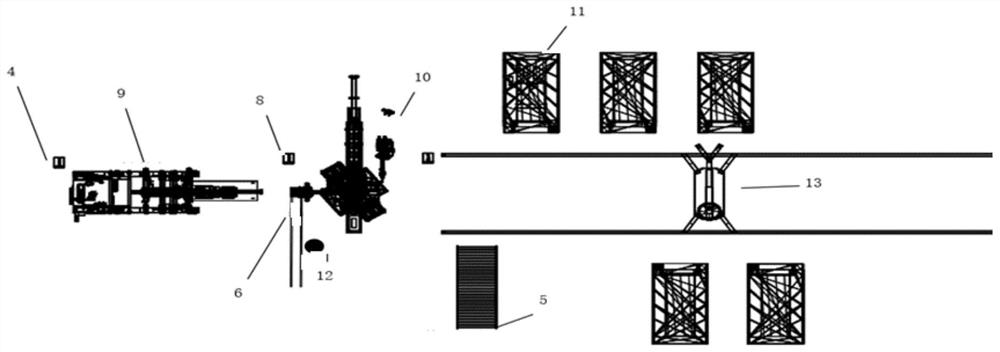

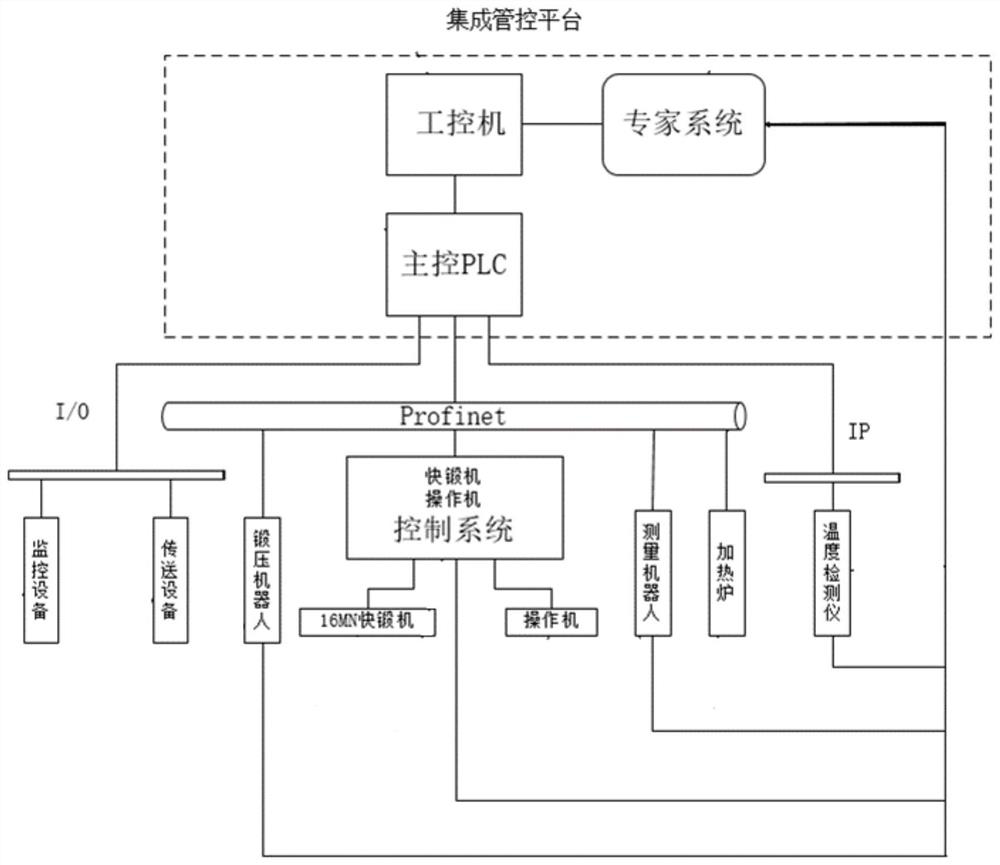

[0045] Such as figure 1 Shown is a schematic diagram of the spindle free forging production unit, including: industrial computer 1, expert system 2, master station PLC 3, monitoring equipment 4, transmission equipment 5, forging robot 6, fast forging machine operator control system 7, fast forging machine 8, Manipulator 9, measuring robot 10, heating furnace 11, temperature detector 12, trailer 13.

[0046] The industrial computer 1 is connected with the main station PLC3 through Ethernet, and the PLC control system is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com