Large-sized high-temperature blade internal defect three-dimensional nondestructive detection method

A technology for internal defect and non-destructive testing, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., can solve problems such as difficult probe scanning detection, inability to measure, and high ray attenuation rate, so as to make up for three-dimensional information Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0041] A three-dimensional nondestructive testing method for internal defects of large high-temperature blades, comprising the following steps:

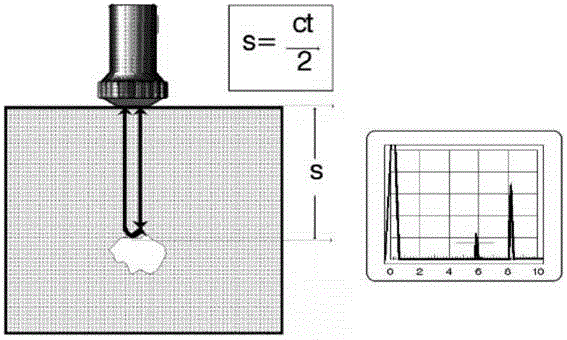

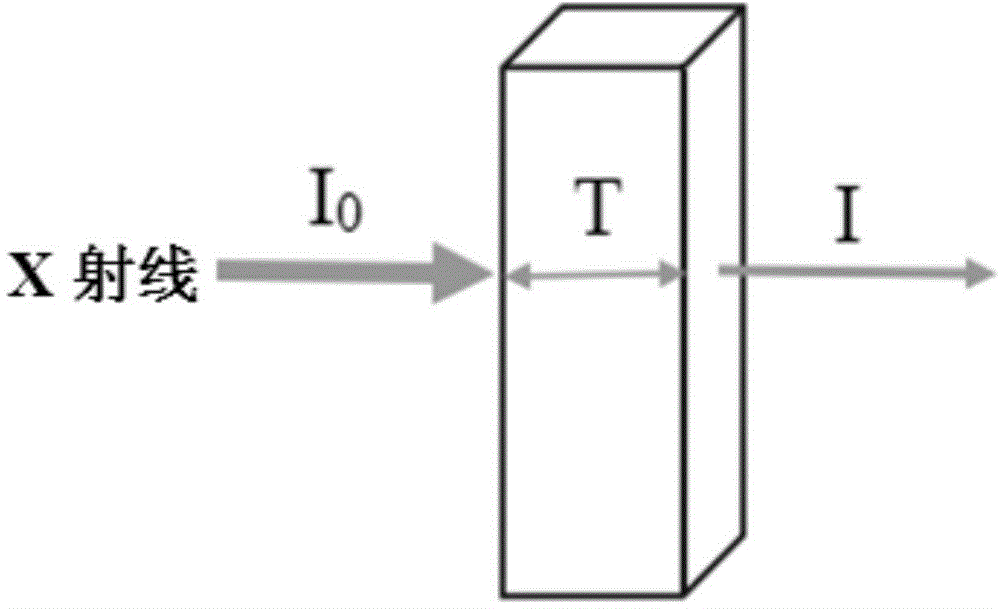

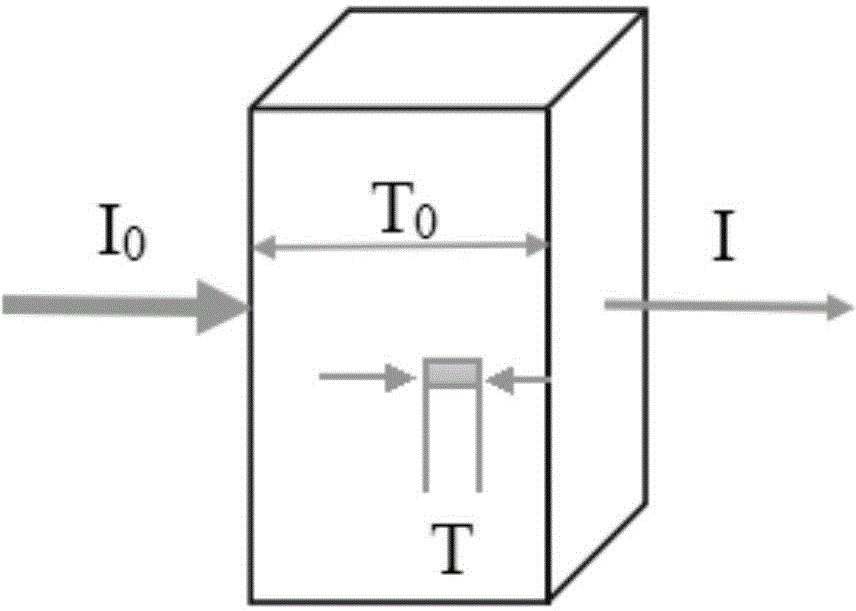

[0042] 1) Use digital ray equipment to conduct internal flaw detection on the front of the gas turbine blade to obtain a two-dimensional grayscale image, and obtain the two-dimensional size and position of the defect by processing the two-dimensional grayscale image, and use the defect attenuation law to process the position of the defect to obtain each For the depth information of a pixel point, the volume of the defect is obtained by using the finite element thinking area and depth calculation for each pixel point, so as to realize the measurement of the three-dimensional volume of the internal defect of the blade;

[0043] Three-dimensional volume measurement of blade internal defects:

[0044] X-rays wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com