A dynamic fault diagnosis method for mechanical assembly of vehicle products

A fault diagnosis and dynamic technology, which is applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems that there is no complete set of dynamic detection and diagnosis technical specifications and standard requirements, and achieve the level of mechanical assembly quality assurance , Intuitive assembly cause and position discrimination, quantification of the effect of dynamic characteristic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

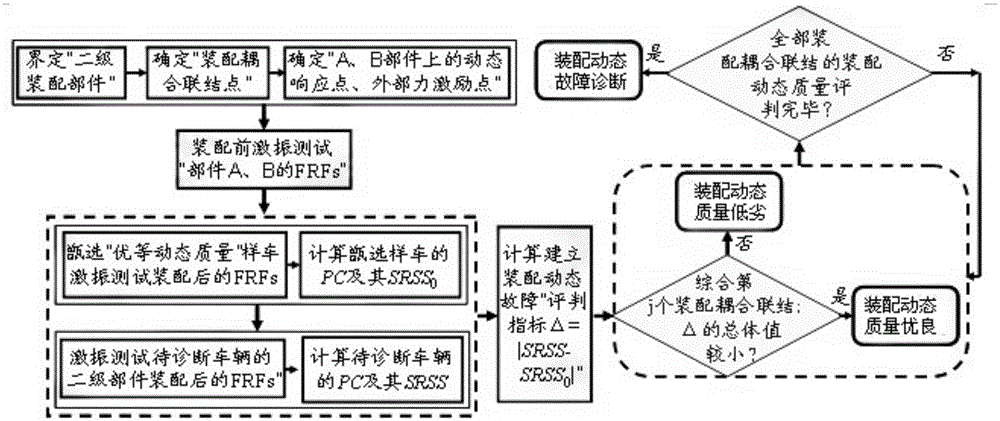

[0035] Such as figure 1 , 2 , 3, a dynamic fault diagnosis method for mechanical assembly of vehicle products, comprising steps in the following order:

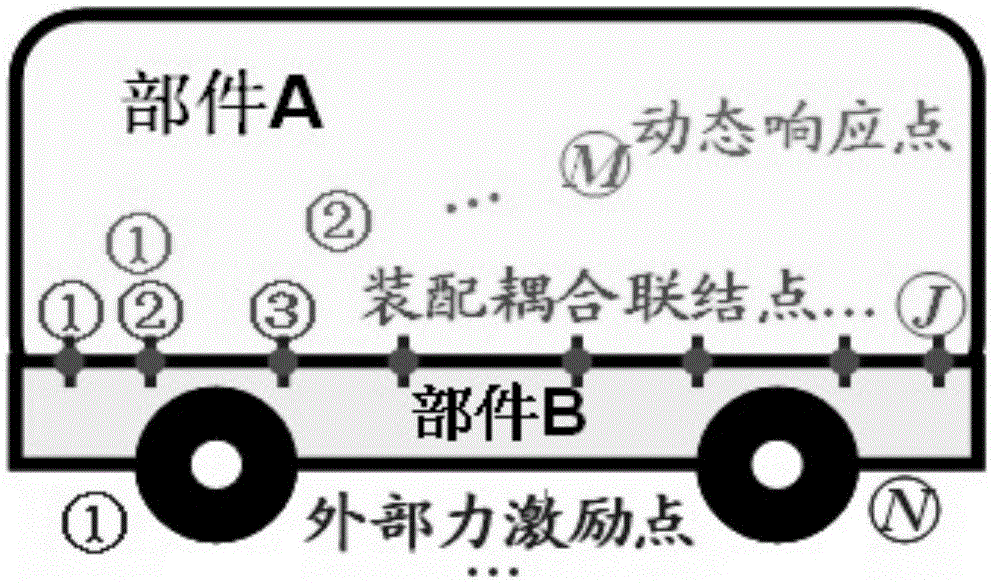

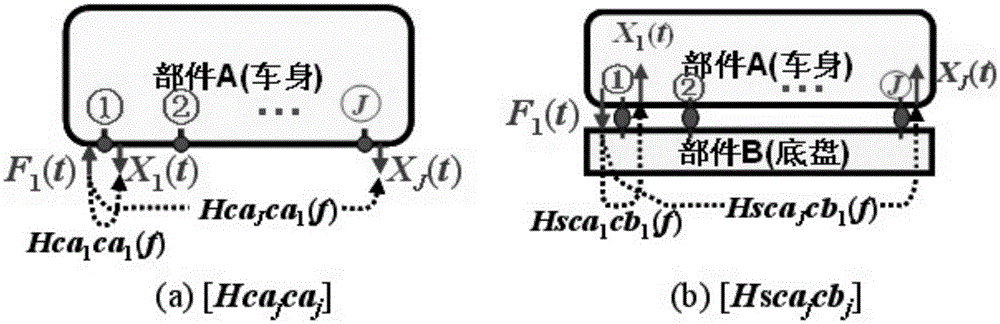

[0036] (1) Define M dynamic response points oa on the component A to be assembled of the vehicle product m (m=1,2,3,...,M), N external dynamic force excitation points ib on component B to be assembled n (n=1, 2, 3,..., N) and J mechanical assembly coupling points ca between parts A and B j 、cb j (j=1,2,3,...,J);

[0037] According to the structural design of this type of vehicle product, it is assumed that the "secondary assembly parts" concerned are the body (A part) and the chassis (B part), and a series of mechanical assembly (welding, bolting, riveting or bonding ), where the number of key assembly coupling points is J=8 (4 on the left and right sides); select and mark the test locations of “dynamic force excitation” and “vibration response” and their number (j=1,2,...,8), they should be as close as possible to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com