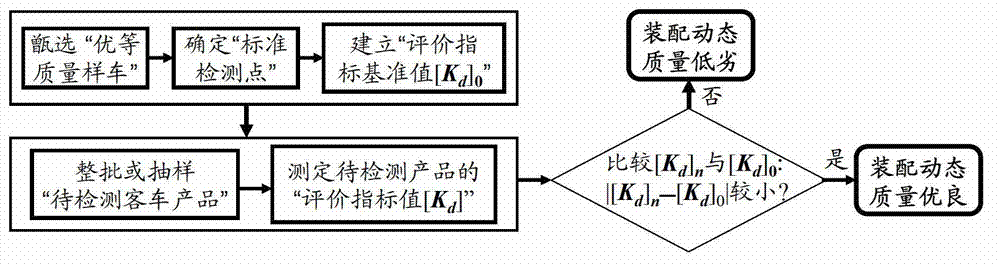

Dynamic quality detection method for whole assembly of automobile products

A quality inspection method and vehicle assembly technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as inability to dynamically control and guarantee quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

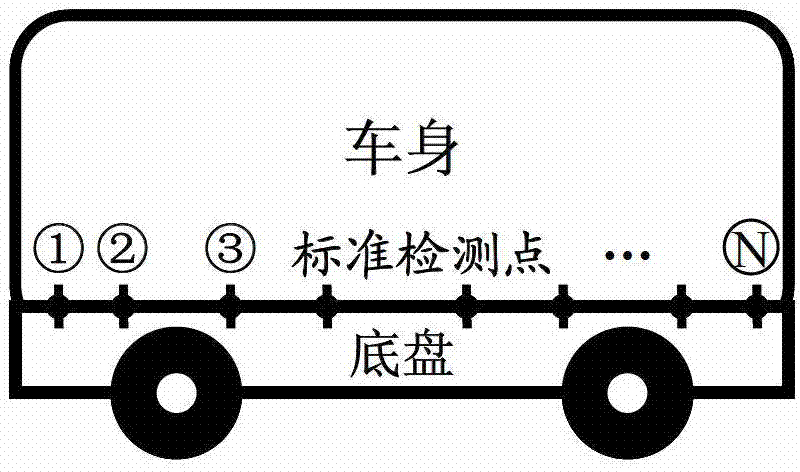

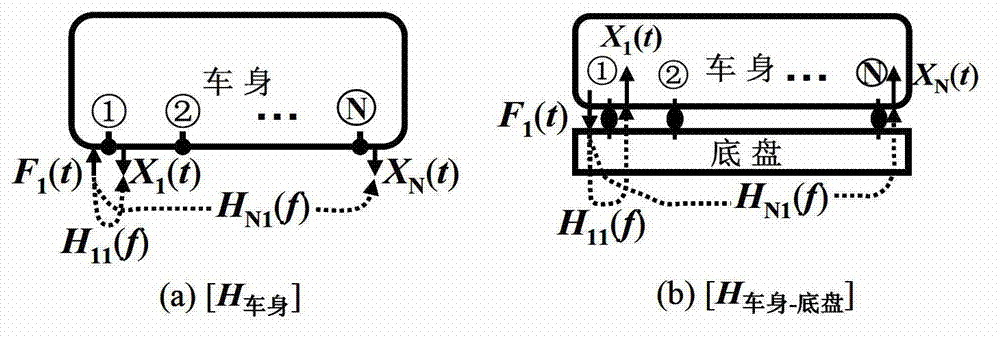

[0029] The present invention is as a kind of dynamic quality detection method of automobile product vehicle assembly, and its evaluation index, standard detection point, evaluation index calculation formula and evaluation index benchmark are respectively specifically as follows:

[0030] (1) Evaluation index: The "dynamic stiffness (Kd)" of the assembly coupling interface between the chassis part and the body part of the automobile is used as the evaluation index of the dynamic quality of the assembly.

[0031] Dynamic stiffness Kd=K+j(2πfC), where K is the static stiffness of the coupling interface (Newton / meter, N / m), C is the damping coefficient of the coupling interface (Newton s / meter, Ns / m), f is the dynamic force excitation frequency (Hz), is an imaginary unit. Dynamic stiffness has been proved by the theory of mechanical structure dynamics that it can be used to accurately and comprehensively describe the dynamic characteristic index of coupling stiffness (resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com