Method for accurate detection of material defect and thickness by using digital radiography transillumination technology

A digital ray and material detection technology, which is applied in the use of radiation for material analysis, measuring devices, and the use of wave/particle radiation, etc., can solve problems such as large residual height fluctuations, differences in final gray levels, and the inability of users to confirm precise positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Time: July 15, 2015

[0074] Workpiece condition: steel plate + slope test block + gradient step test block

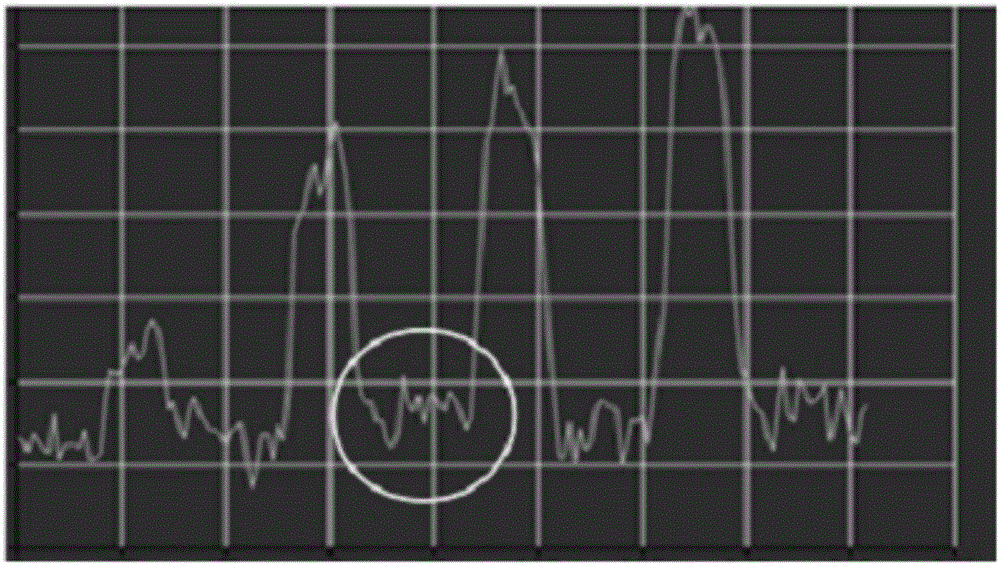

[0075] Test purpose: to verify the use of a fixed slope test block to measure the depth difference between two defects in a gradient test block with a (steel plate) background (simulate the height of the defect inside the weld)

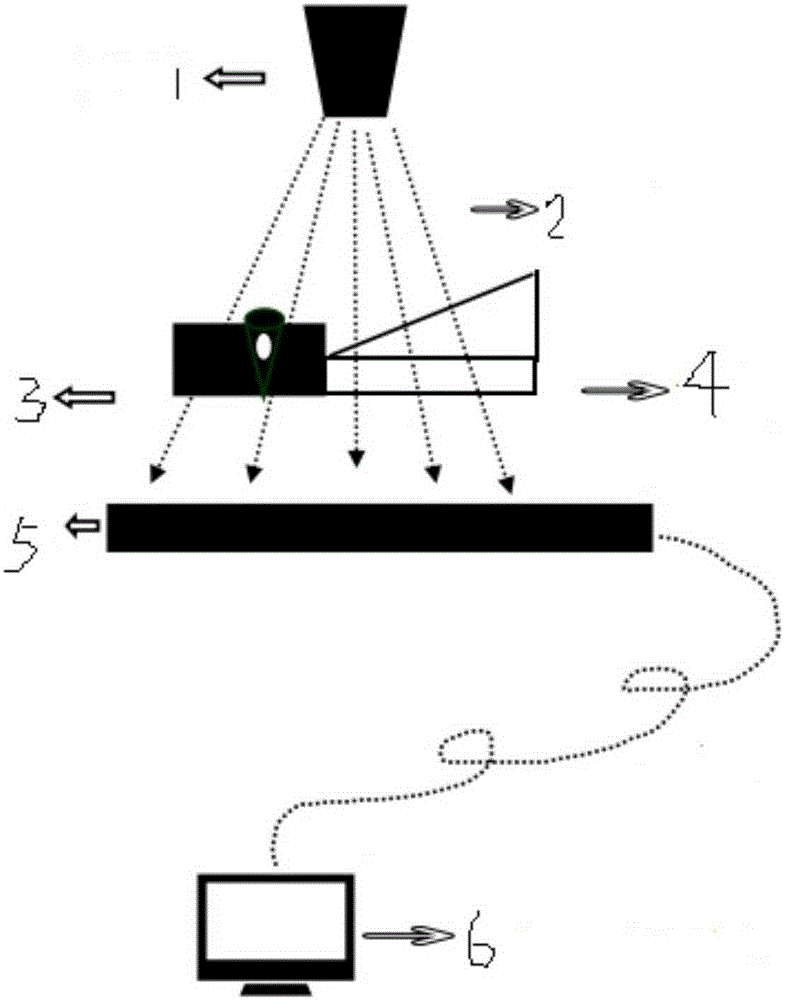

[0076] Introduction of the equipment used:

[0077] Equipment: U.S. Varian 2520 flat panel detector

[0078] Using CP160 radiographic machine from Belgium ICM

[0079] Description of workpiece and test block:

[0080] 1. 7mm thick steel plate as background (simulating the thickness of pipe or flat plate)

[0081] 2. 3.5mm thick test block with 5 step grooves (see the above table H.2II type comparison test block, the depth is 0.5, 1.0, 1.5, 2.0, 2.5), we only use the first defect (depth 0.5mm , The depth difference between the actual remaining thickness of the test block 3mm) and the second defect (depth 1mm, the actual remaining thickness of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com