Method for representing residual stress of film

A residual stress and thin film technology, applied in the field of thin film characteristic characterization, can solve problems affecting the performance of integrated circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

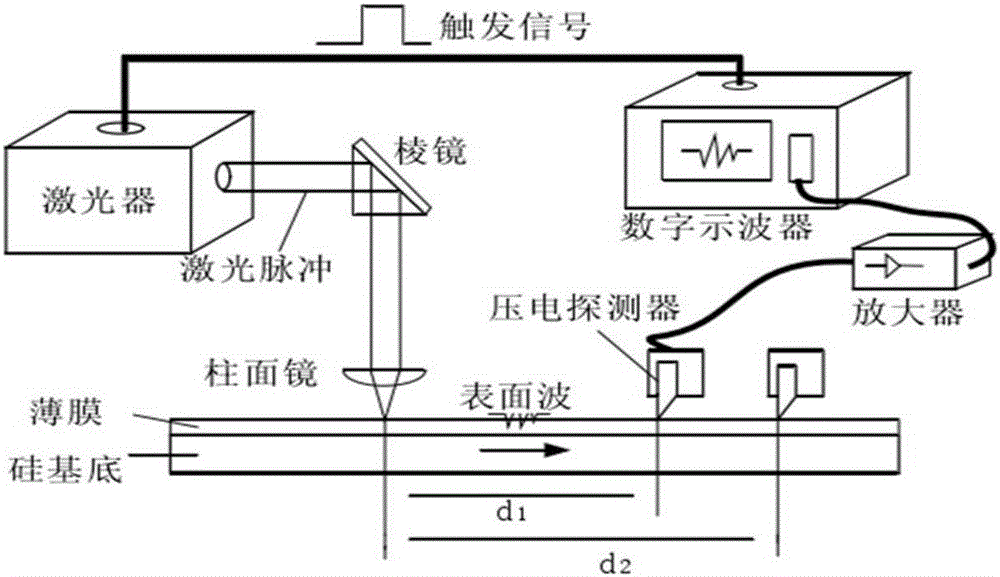

[0016] The test curve of the surface acoustic wave propagating on the sample surface was measured by the laser-excited surface acoustic wave experimental system, and the schematic diagram of the laser-excited surface acoustic wave detection system for residual stress of the film is as follows figure 1 As shown, the MNL 801S nitrogen molecular laser is used, the wavelength is 337.1nm, and the average pulse energy is 400uJ. The piezoelectric sensor consists of a polyvinylidene fluoride film (PVDF) and a self-made wedge probe. The amplifier is MITEQ AU-1338 type high frequency broadband voltage amplifier, the digital oscilloscope adopts Tektronics TDS3000B type, the bandwidth is 300MHz, and the highest sampling rate is 2.5GS / s. The sample used in the experiment is a film / substrate structure. In order to make the results more accurate, it is necessary to ensure that the measured samples belong to the same batch and have highly similar Young's modulus, density and Poisson's ratio. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com